Flangeless Forming Method for Thin-Wall Metal Sheet Metal Components

A metal component without flange technology, which is applied in the field of thin-walled metal component forming and manufacturing. It can solve the problems of slab size and width not meeting the requirements, wrinkling or cracking in the flange area, and metal thin-walled sheet metal components without flanges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

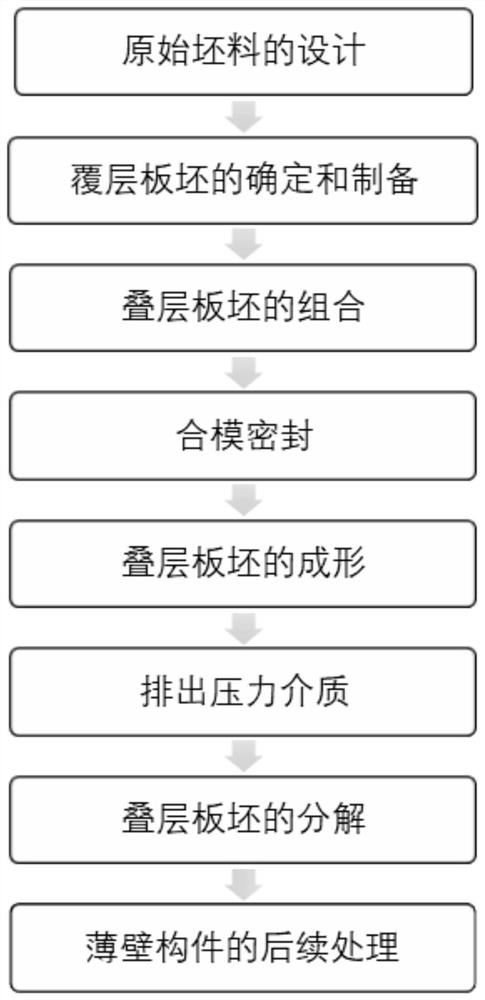

[0030] Example 1: Combining figure 1 , figure 2 , image 3 ,Figure 4, Figure 5 , Figure 6 Illustrate, the non-flange forming method of the thin-walled metal sheet metal component that the present invention proposes, this method is to carry out according to the following steps:

[0031] The invention provides a flangeless forming method of a thin-walled metal sheet metal member, comprising the following steps:

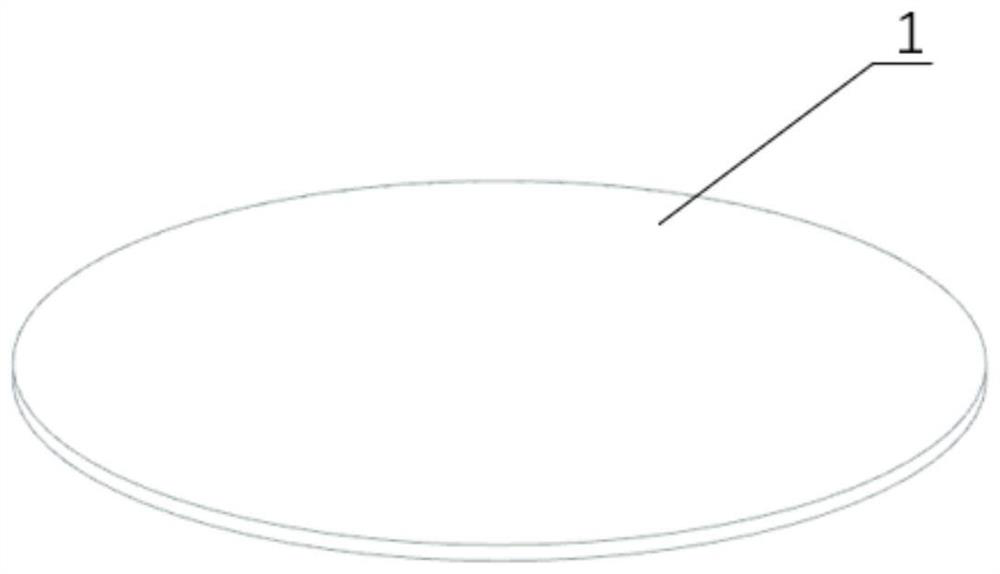

[0032] Step 1, the design of the original blank. Carry out feature analysis on thin-walled metal components, and determine the material and outline dimensions of the original slab required by theoretical calculation or simulation methods. Since the forming of the original slab does not require a flange area, the size of the original slab is selected It is consistent with the maximum cross-sectional size of the parting surface of the mold, and then it is prepared by cutting with a blank cutting machine or punching through a blanking die;

[0033] Step 2: Determi...

Embodiment 2

[0041] Example 2: Combining figure 1 Note that in step 1, the selected original slab is made of 5A06 aluminum alloy with a thickness of 2mm and a circle with a diameter of 150mm for the outer dimensions. Other steps are the same as in embodiment 1.

[0042] The beneficial effects of this embodiment are: the 5A06 aluminum alloy has high specific strength, strong corrosion resistance and good weldability, and is widely used in parts such as fairings and fuel storage tanks in aviation and aerospace fields.

Embodiment 3

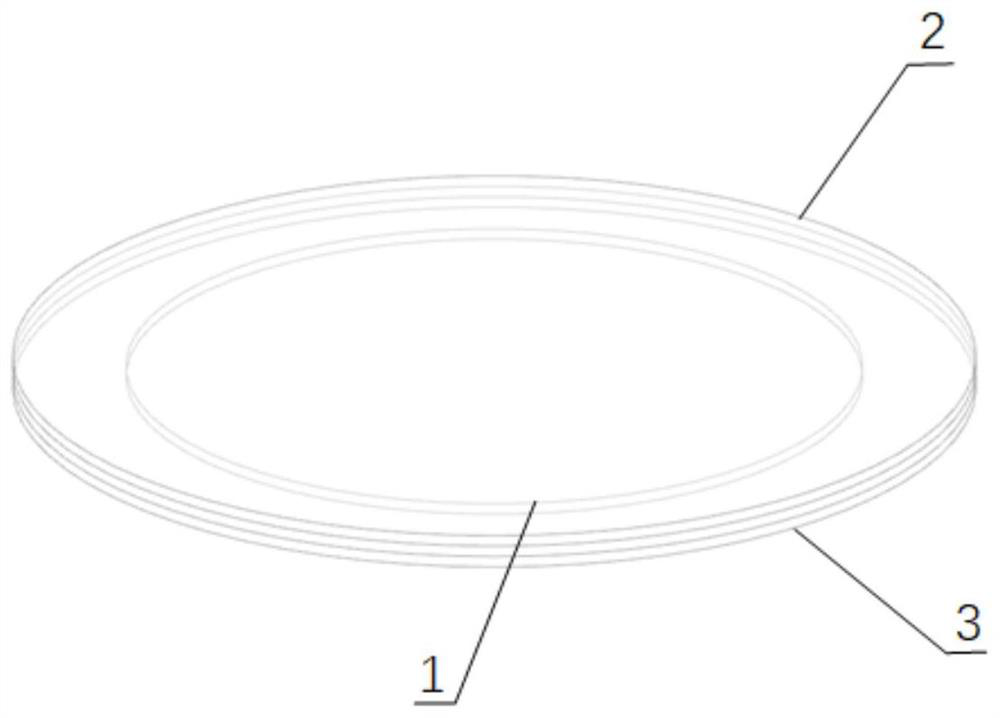

[0043] Example 3: Binding figure 2 Note that in step 2, the material of the upper cladding slab and the lower cladding slab is 1Cr18Ni9Ti stainless steel plate with a thickness of 1mm, and a circle with a diameter of 200mm is selected as the outer dimension. The other steps are the same as in Example 1.

[0044] The beneficial effects of this embodiment are: 1Cr18Ni9Ti has good overall performance, high plasticity and toughness, and its elongation, reduction of area and impact value are all high, and the elongation of 1Cr18Ni9Ti is 40%. Through the upper and lower stainless steel clad slabs , reducing the two-way tensile stress at the top and bottom of the original slab, reducing the stress and strain gradients in the deformation zone of the original slab, and making the stress and strain distribution in the entire bulging zone more uniform, thereby making the bulging deformation more uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com