High-temperature molten flow destroying unexploded ordnance system

A technology of unexploded ammunition and melt flow, applied in blasting and other directions, can solve the problems of not fully guaranteeing the normal function of ammunition, reducing the stability and safety of ammunition, and limited life of ammunition, so as to improve safety and operational efficiency, reduce Explosion hazard, highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the text of the description.

[0033] It should be understood that terms such as "having", "including" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

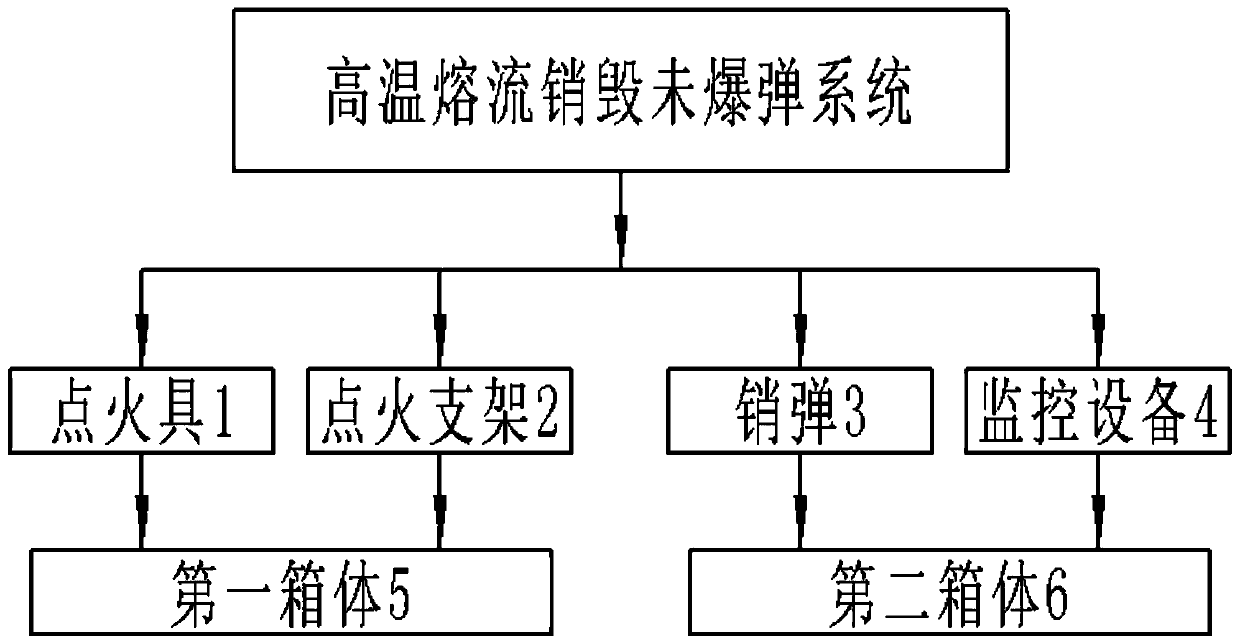

[0034] Such as figure 1 , figure 2 As shown, the present invention provides a high-temperature molten stream destroying unexploded ordnance system, including:

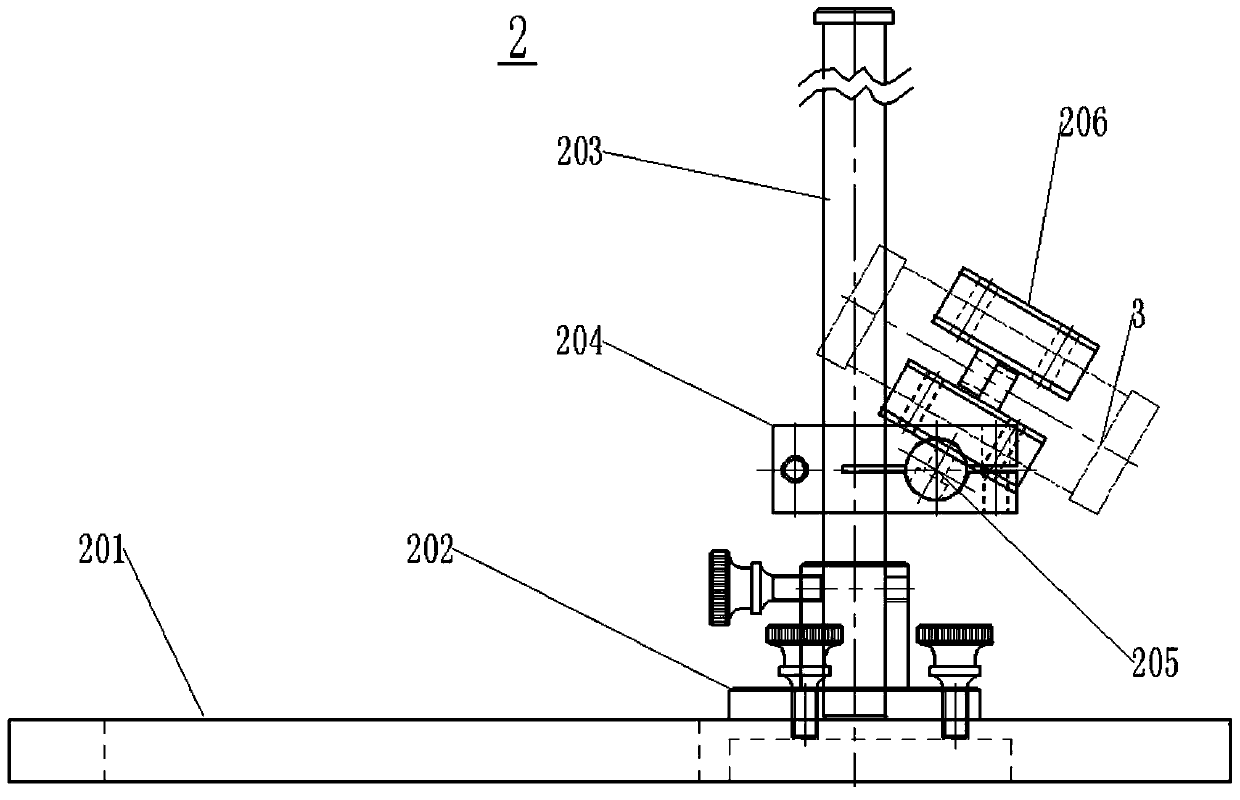

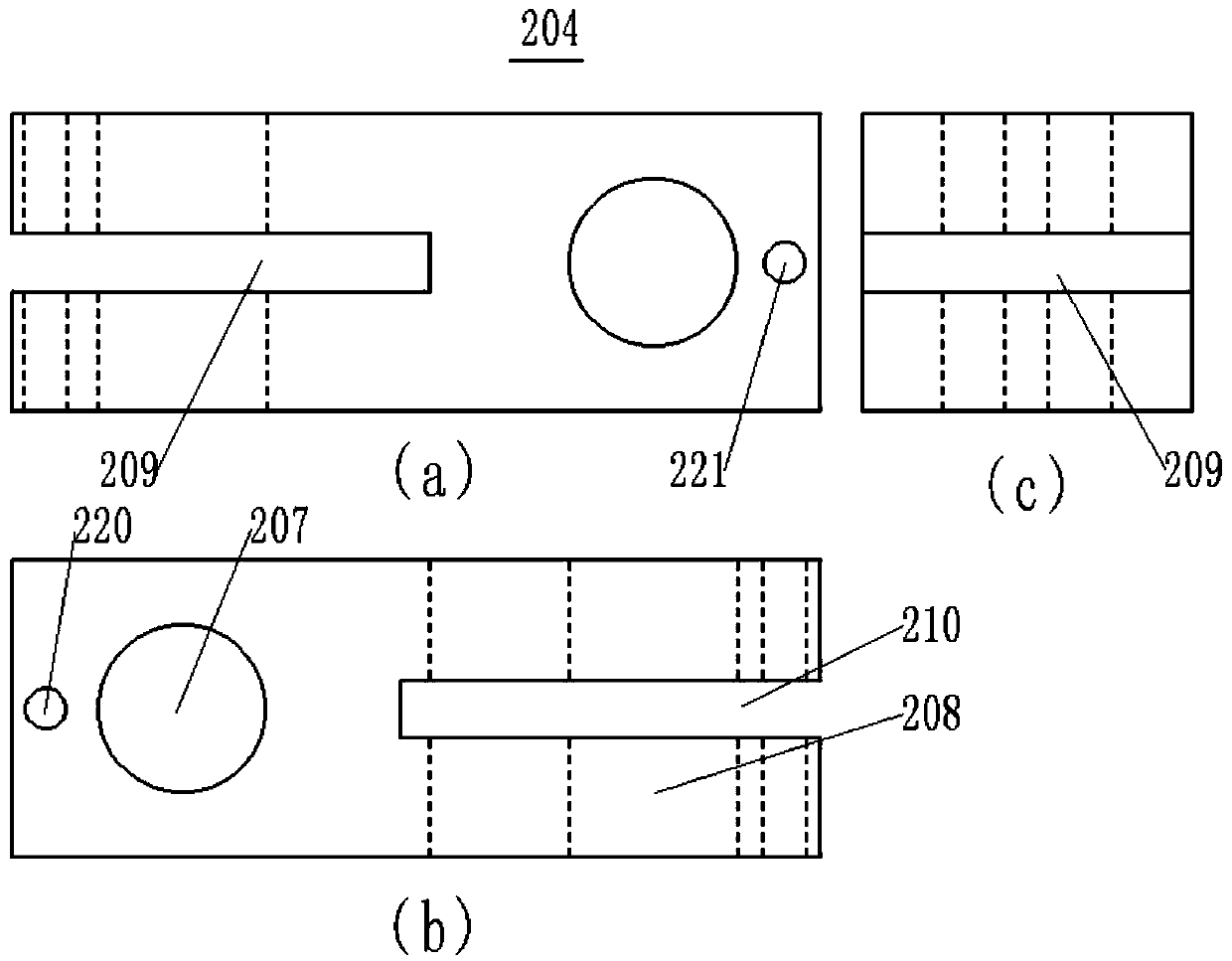

[0035] The ignition device 1, the ignition support 2, the pin bullet 3, and the monitoring device 4. The ignition device 1, the ignition support 2 can be selectively arranged in the first case 5, the pin bomb 3, the monitoring device 4 can be selectively arranged in the second box 6; wherein, when in use, the pin bomb 3 is erected on the ignition support 2, and the ignition device 1 is electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com