A kind of graphene anticorrosion primer for heat exchanger in marine environment and preparation method thereof

A marine environment, anti-corrosion primer technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of performance that cannot meet the new generation of high-end equipment, performance degradation, easy oxidation, etc., and achieve large-scale industrial production , optimize thermal conductivity, enhance the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

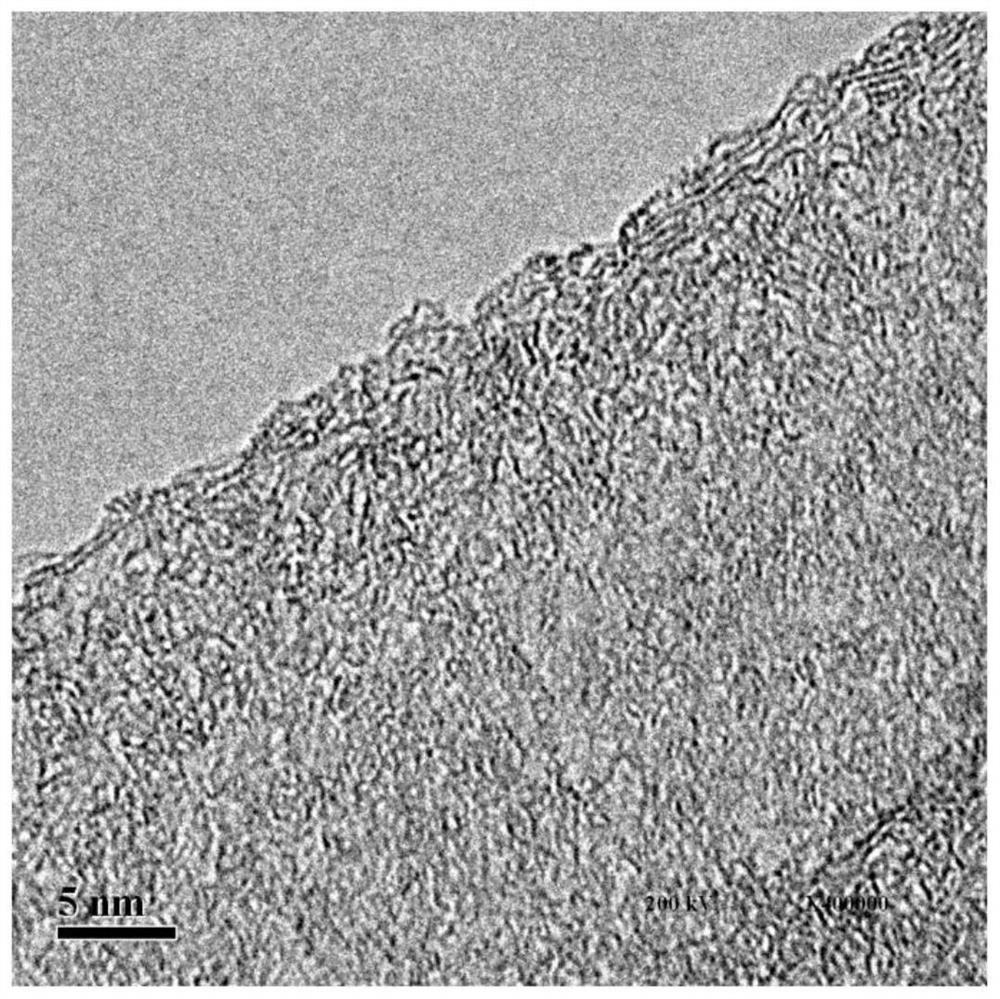

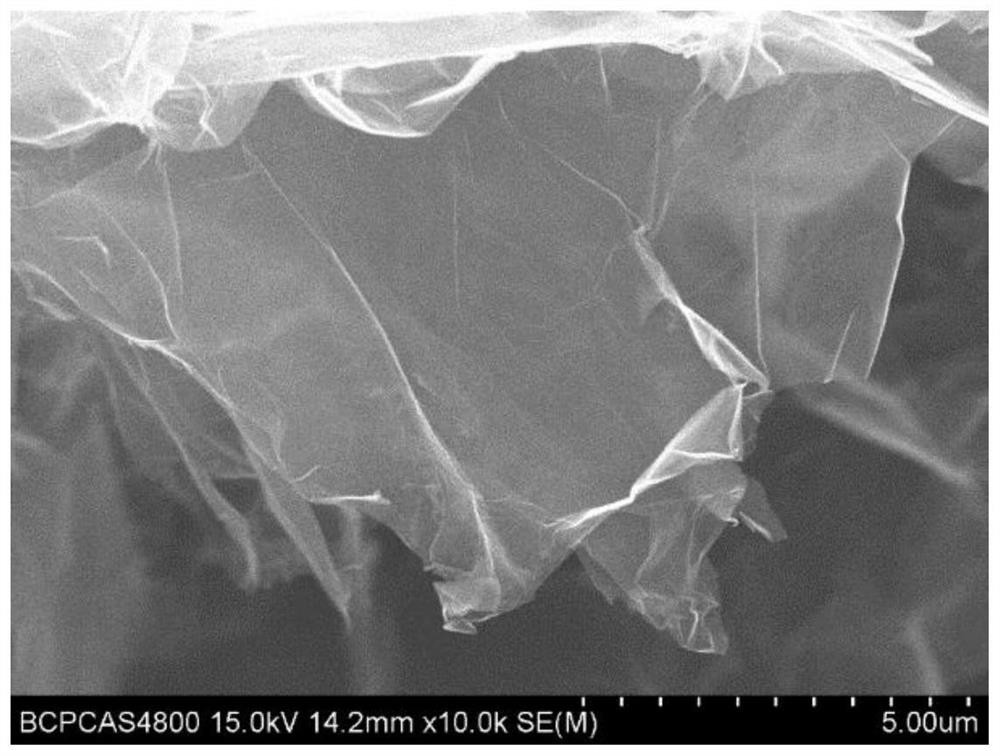

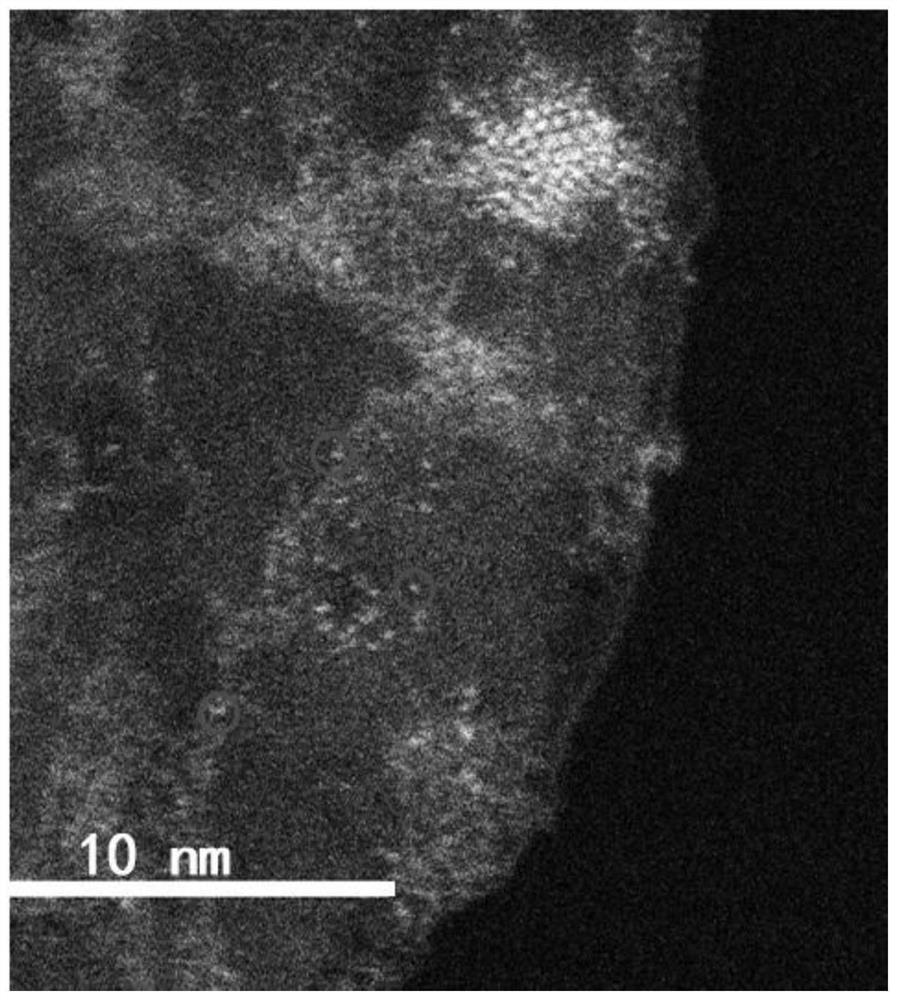

[0101] 1. Preparation of atomic metal-covered graphene

[0102] The dimethyl carbonate solution added with ferric chloride and perchloric acid is used as the electrolyte, the mass fraction of ferric chloride is 1%, and the mass concentration of perchloric acid is 30%; the flexible graphite paper with a thickness of 1mm is used as the positive electrode Plates and negative electrode plates are placed in a 100L small electrolytic cell in the form of positive and negative arrays; a 5.0V voltage is applied through a DC power supply to form a strong electric field between the positive electrode plate and the negative electrode plate, and perchlorate ions are used for intercalation exfoliated graphene.

[0103] After 60 hours of electrolysis, filter the electrolyte, collect the precipitate, put it in ultrapure water for ultrasonic washing, the ultrasonic frequency is 30kHz, and the ultrasonic time is 2h; the ultrasonic product is collected again, centrifuged and enriched at 6000r / mi...

Embodiment 2

[0116] 1. Preparation of atomic metal-covered graphene

[0117] The dimethyl carbonate solution added with ferric chloride and perchloric acid is used as the electrolyte, the mass fraction of ferric chloride is 1%, and the mass concentration of perchloric acid is 30%; the flexible graphite paper with a thickness of 1mm is used as the positive electrode Plates and negative electrode plates are placed in a 100L small electrolytic cell in the form of positive and negative arrays; a 5.0V voltage is applied through a DC power supply to form a strong electric field between the positive electrode plate and the negative electrode plate, and perchlorate ions are used for intercalation exfoliated graphene.

[0118] After 60 hours of electrolysis, filter the electrolyte, collect the precipitate, put it in ultrapure water for ultrasonic washing, the ultrasonic frequency is 30kHz, and the ultrasonic time is 2h; the ultrasonic product is collected again, centrifuged and enriched at 6000r / mi...

Embodiment 3

[0130] 1. Preparation of atomic metal-covered graphene

[0131] The dimethyl carbonate solution added with ferric chloride and perchloric acid is used as the electrolyte, the mass fraction of ferric chloride is 2%, and the mass concentration of perchloric acid is 30%; the flexible graphite paper with a thickness of 1mm is used as the positive electrode plate And the negative electrode plate is placed in a small 100L electrolytic cell in the form of positive and negative arrays; a 5.0V voltage is applied through a DC power supply to form a strong electric field between the positive electrode plate and the negative electrode plate, and perchlorate ions are used for intercalation and stripping Graphene.

[0132] After 60 hours of electrolysis, filter the electrolyte, collect the precipitate, put it in ultrapure water for ultrasonic washing, the ultrasonic frequency is 30kHz, and the ultrasonic time is 2h; the ultrasonic product is collected again, centrifuged and enriched at 6000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com