Chuck structure for rapidly clamping shaft workpieces

A shaft workpiece and chuck structure technology, applied in the field of machinery, can solve the problems affecting the processing efficiency and processing accuracy, the workpiece is easy to loosen, and the processing efficiency is greatly affected, and achieves high firmness and coaxiality, reliable clamping, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

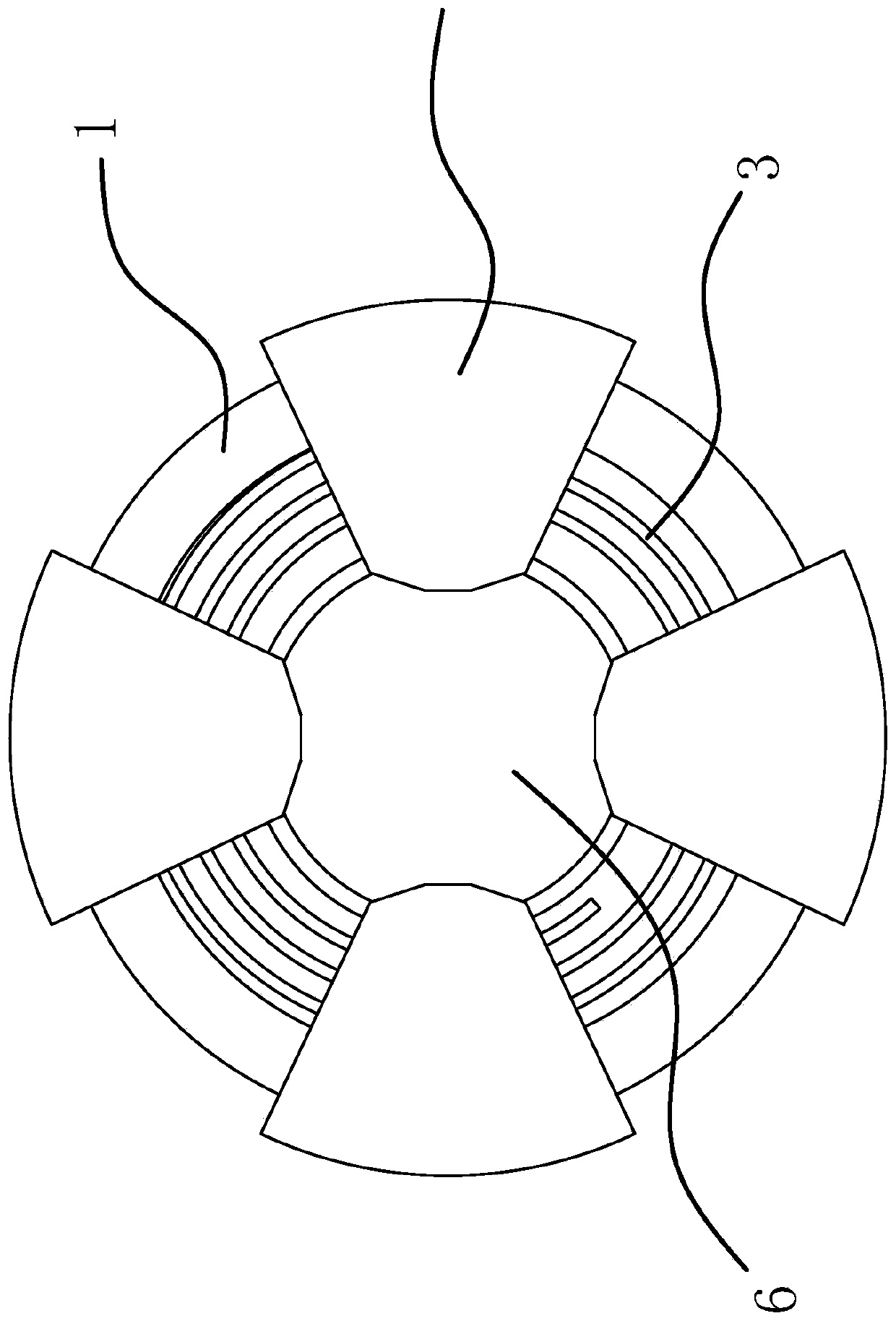

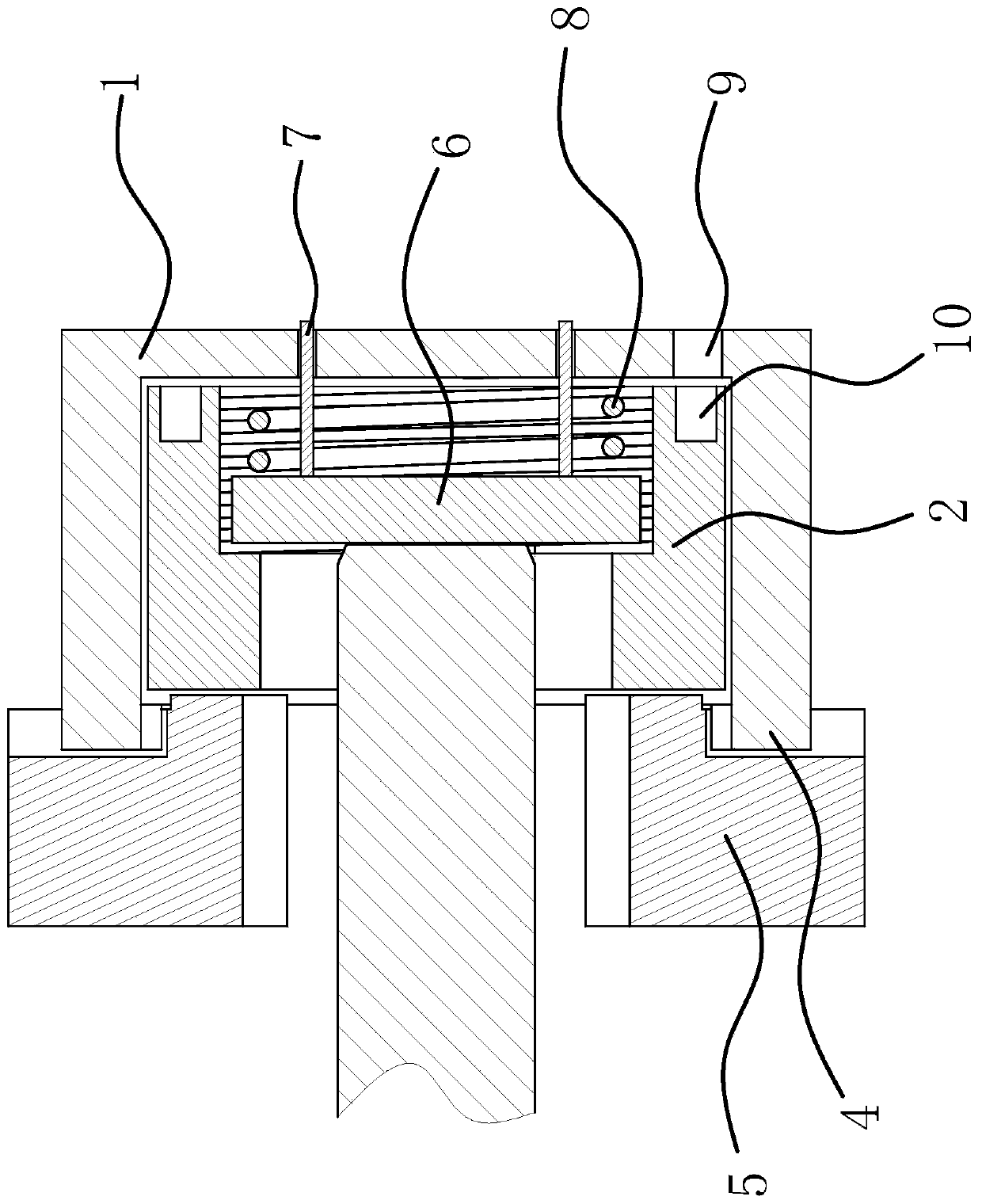

[0016] Such as figure 1 and figure 2 As shown, the chuck structure has a cylindrical body 1, one end of the body 1 is open, and a hollow sleeve 2 is arranged inside the body 1, the peripheral surface of the sleeve 2 is connected with the thread in the middle of the inner wall of the body 1, and the sleeve 2 is close to the body 1 There is a spiral groove 3 on the end surface of the opening end, and a number of guide blocks 4 are evenly arranged on the upper surface of the body 1 close to the end surface of the opening, and a caliper 5 is slidably connected to the guide block 4 along the radial direction of the body 1. The caliper 5 has a A number of threaded ribs corresponding to the spiral groove 3, the end of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com