Reaction temperature stability maintaining system of system for producing adipic acid by nitric acid oxidation method

A nitric acid oxidation method and reaction temperature technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as temperature unevenness, achieve improved cooling effect, good economy Benefits, the effect of achieving stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

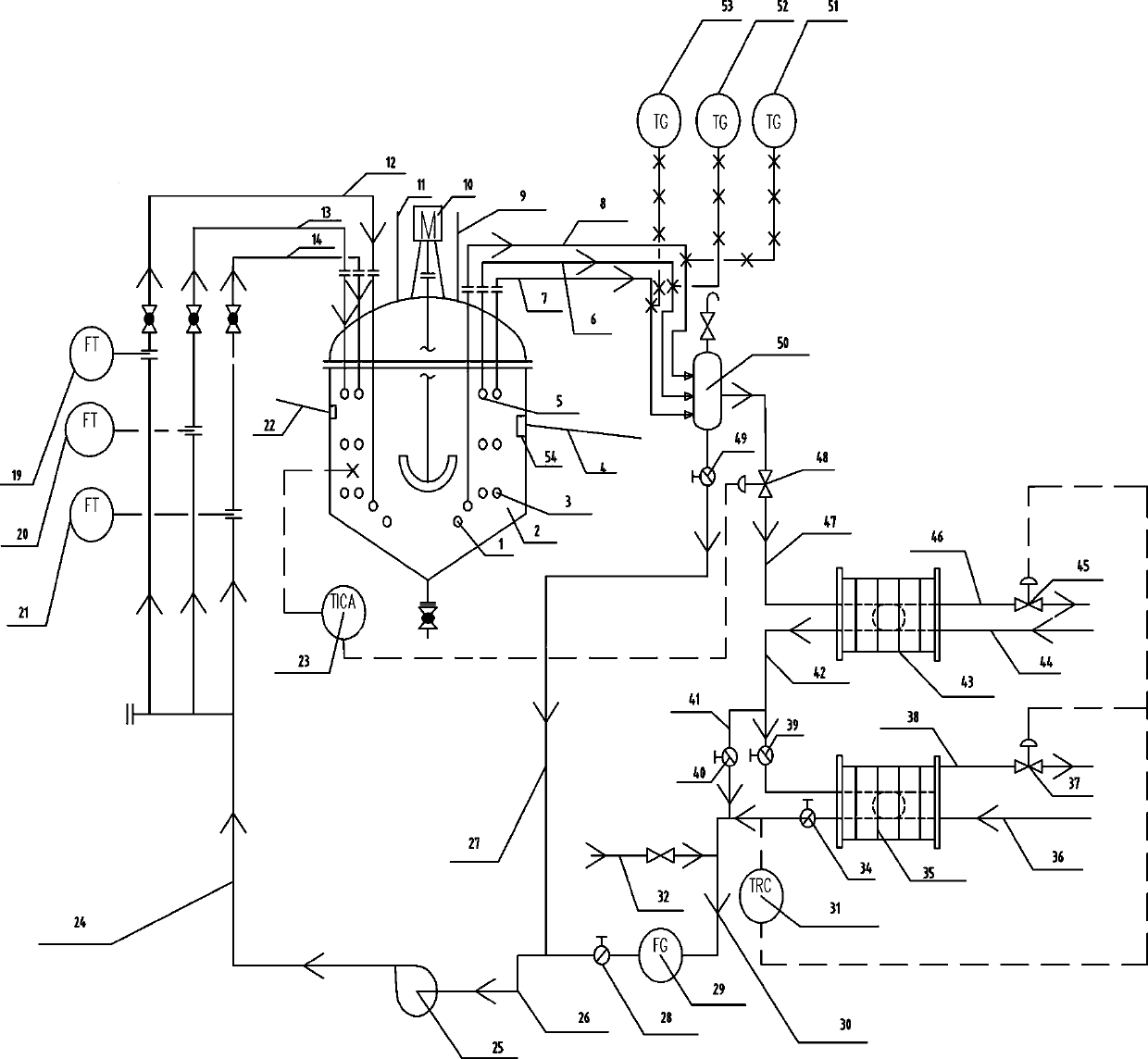

[0026] Such as figure 1 As shown, a reaction temperature maintenance system for producing adipic acid system by nitric acid oxidation method includes a reactor 2, the reactor 2 adopts the adipic acid reactor in the prior art, and the reactor 2 is provided with a gas phase port 9. The stirring paddle 10 and the second feeding pipe 11, the middle part of the reaction kettle 2 is provided with a first feeding pipe 22 and a discharge pipe 4, the outlet of the first feeding pipe 22 and the inlet of the discharge pipe 4 are provided with a baffle 54, And same as the prior art, the inner coil pipe 5 and the outer coil pipe 3 which are all spirally extending along the axial direction of the reactor are provided in the reactor 2 from the inside to the outside, and the bottom of the reactor is provided with There is a lower coil 1, cooling water circulates in the inner coil 5, outer coil 3 and lower coil 1, and the outlets of the inner coil 5, outer coil 3 and lower coil 1 are respectiv...

Embodiment 2

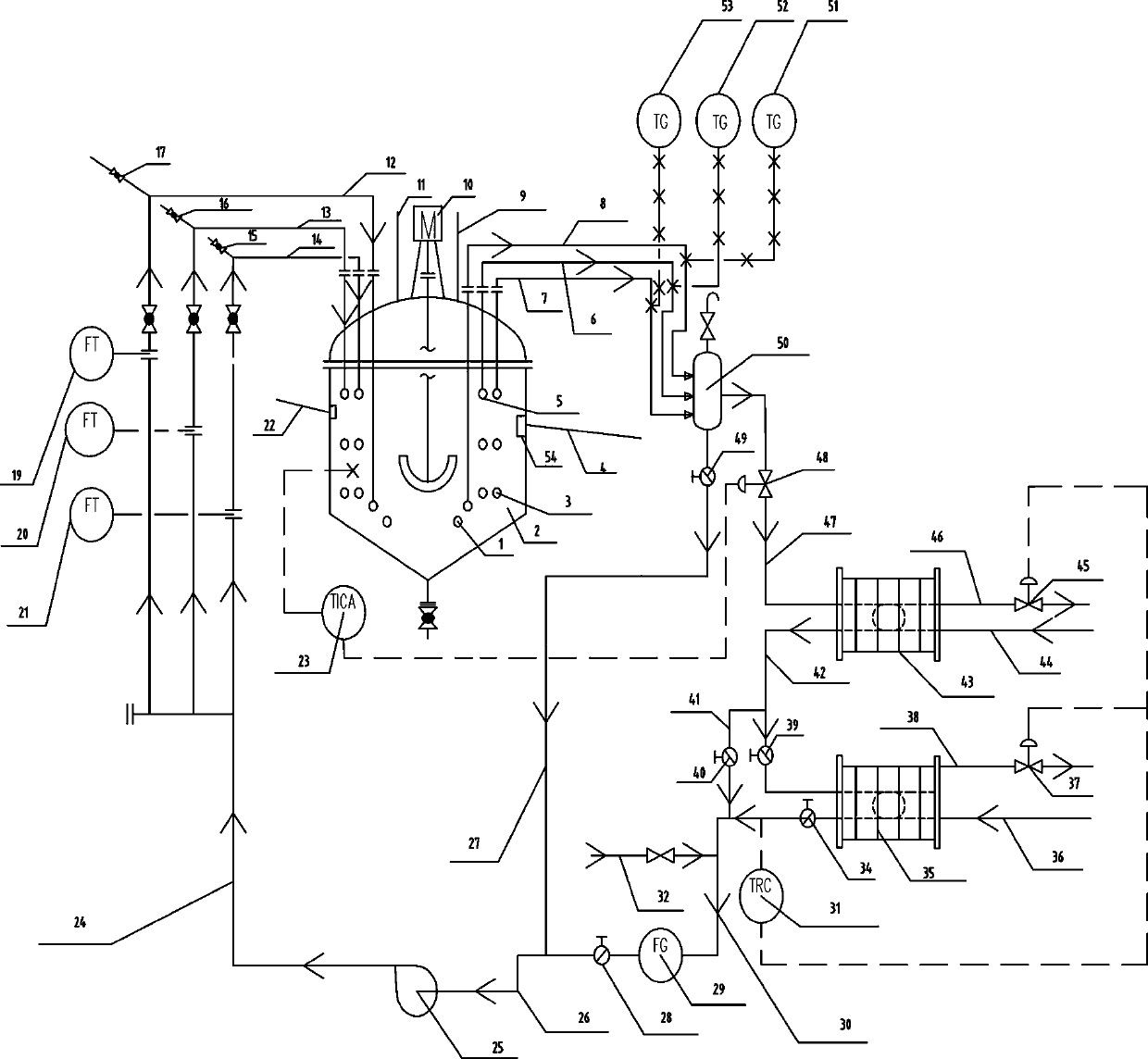

[0037] Such as figure 2 As shown, a reaction temperature maintenance system for producing adipic acid system by nitric acid oxidation method includes a reactor 2, the reactor 2 adopts the adipic acid reactor in the prior art, and the reactor 2 is provided with a gas phase port 9. The stirring paddle 10 and the second feeding pipe 11, the middle part of the reaction kettle 2 is provided with a first feeding pipe 22 and a discharge pipe 4, the outlet of the first feeding pipe 22 and the inlet of the discharge pipe 4 are provided with a baffle 54, And same as the prior art, the inner coil pipe 5 and the outer coil pipe 3 which are all spirally extending along the axial direction of the reactor are provided in the reactor 2 from the inside to the outside, and the bottom of the reactor is provided with There is a lower coil 1, cooling water circulates in the inner coil 5, outer coil 3 and lower coil 1, and the outlets of the inner coil 5, outer coil 3 and lower coil 1 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com