Self-defoaming electric cooker

A rice cooker and defoaming technology, which is applied in the directions of preventing overflow, cooking utensils, household utensils, etc., can solve the problems of liquid overflow, residual bubbles, poor foam breaking effect of convex ribs, etc., and achieves the effect of improving efficiency and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

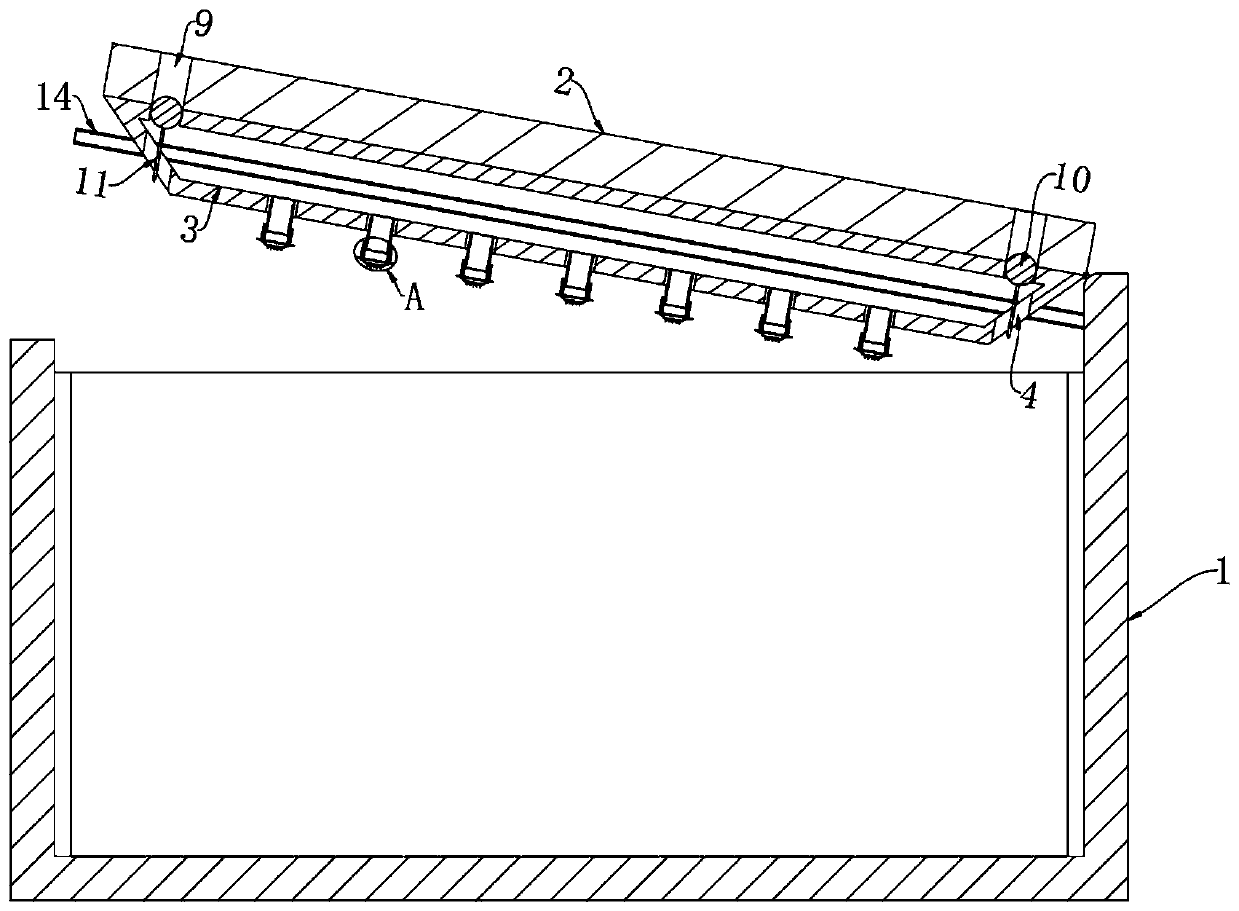

[0023] Such as Figure 1-2 As shown above, the self-defoaming rice cooker includes a rice cooker body 1, a cover plate 2 is arranged on the rice cooker body 1, and two second through holes 9 opposite to the first through holes 4 are opened on the cover plate 2. Hole 9 is provided with airtight ball 10, the lower end opening diameter of the second through hole 9 is slightly smaller than the diameter of airtight ball 10, the width of the upper end opening of the second through hole 9 is slightly less than the diameter of airtight ball 10, and the length of upper end opening is greater than The diameter of the airtight ball 10 and the structural design of the second through hole 9 can ensure that the air pressure is too high, and the airtight ball 10 will not be pushed out of the second through hole 9 when the airtight ball 10 is pushed up, and the airtight ball 10 can rise. During the process, a gap is formed in the second through hole 9 to facilitate pressure relief. When the s...

Embodiment 2

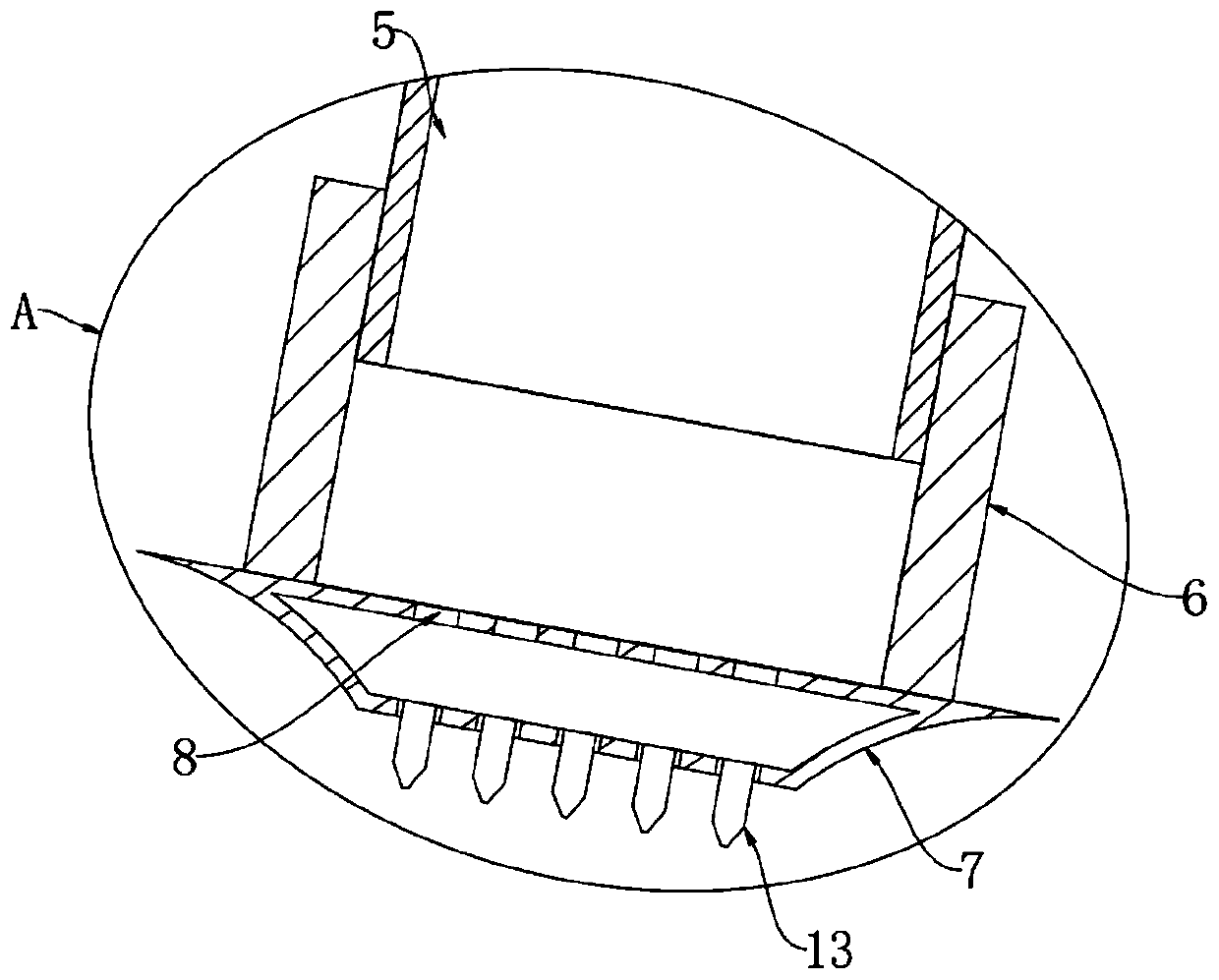

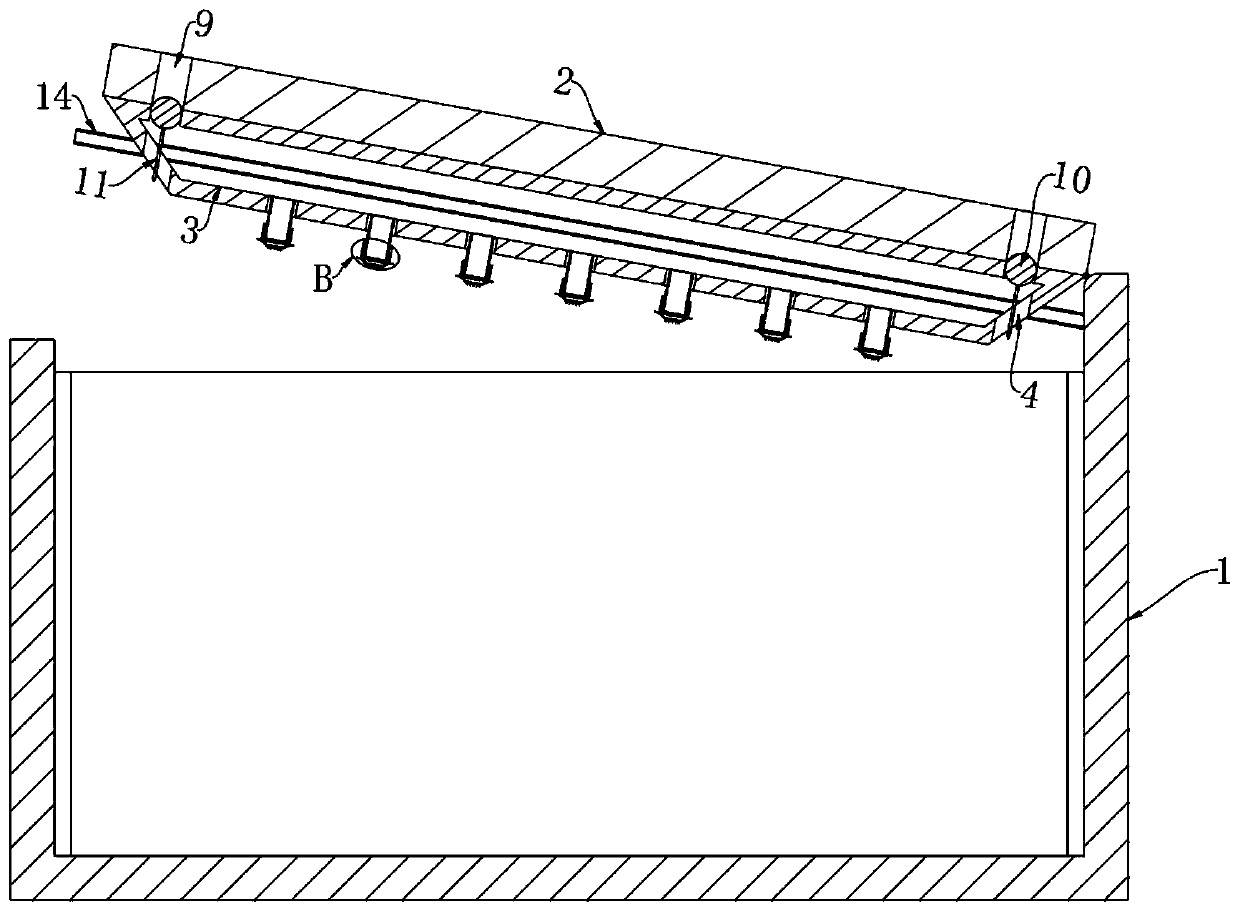

[0026] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the hollow tube 6 is sleeved on the communicating tube 5, and the hollow tube 6 is slidably connected with the communicating tube 5, and the baffle plate 7 and the communicating tube 5 are fixedly connected with a A plurality of return springs 12, when the steam acts on the baffle 7 through the connecting pipe 5, the baffle 7 will slide down through the hollow tube 6, and pull the return spring 12 at the same time, while the baffle 7 is sliding down, the needle-shaped tube 13 can be used to Structural features, puncture the air bubbles in the attachment, when the airtight ball 10 rises, when the pressure is released, the force of the steam weakens, and the baffle 7 will slide up the baffle 7 under the reaction force of the return spring 12, due to the return spring 12, the baffle 7 will vibrate up and down to a certain extent after returning to its position, and then drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com