Apparatus and method for assembling a strip to a tread

A strip and tread technology, applied in tires, applications, household appliances, etc., can solve problems such as difficult to handle conductive strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the context of this application, a material or compound that is a very weak conductor means a material or compound with a resistance greater than or equal to 10 8 Ohmic material, conductive material or compound is one with a resistance of less than 10 6 ohmic material.

[0047] In the present invention, the term longitudinal or longitudinally is used to denote the direction corresponding to the longitudinal direction of the tread, which is in the form of a flat strip before being added to the green annular tire assembly. The term transverse means a direction perpendicular to the longitudinal direction of the tread.

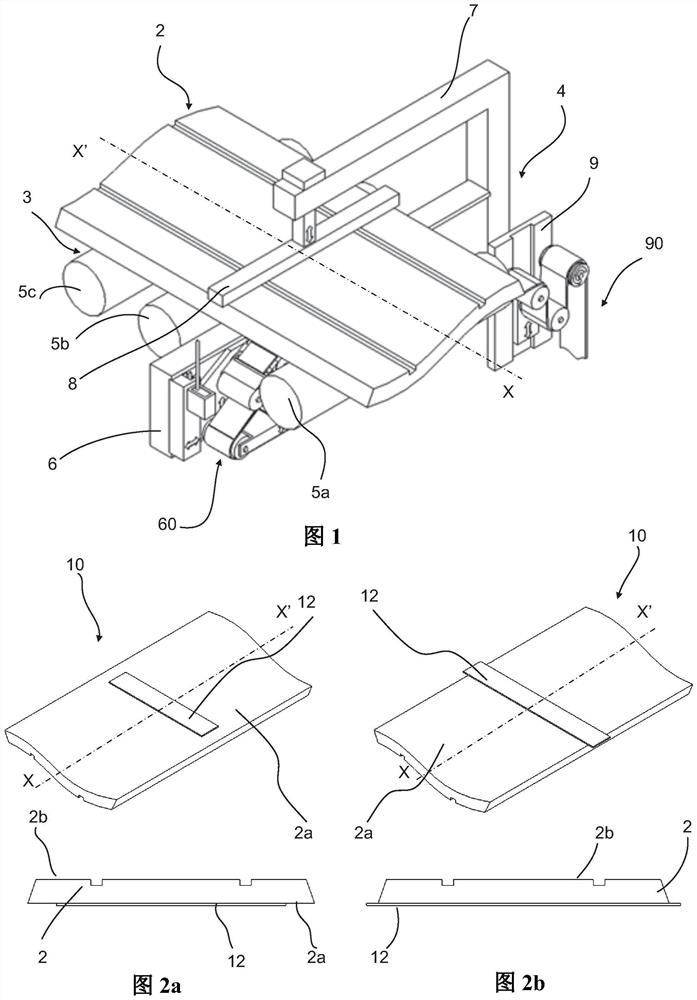

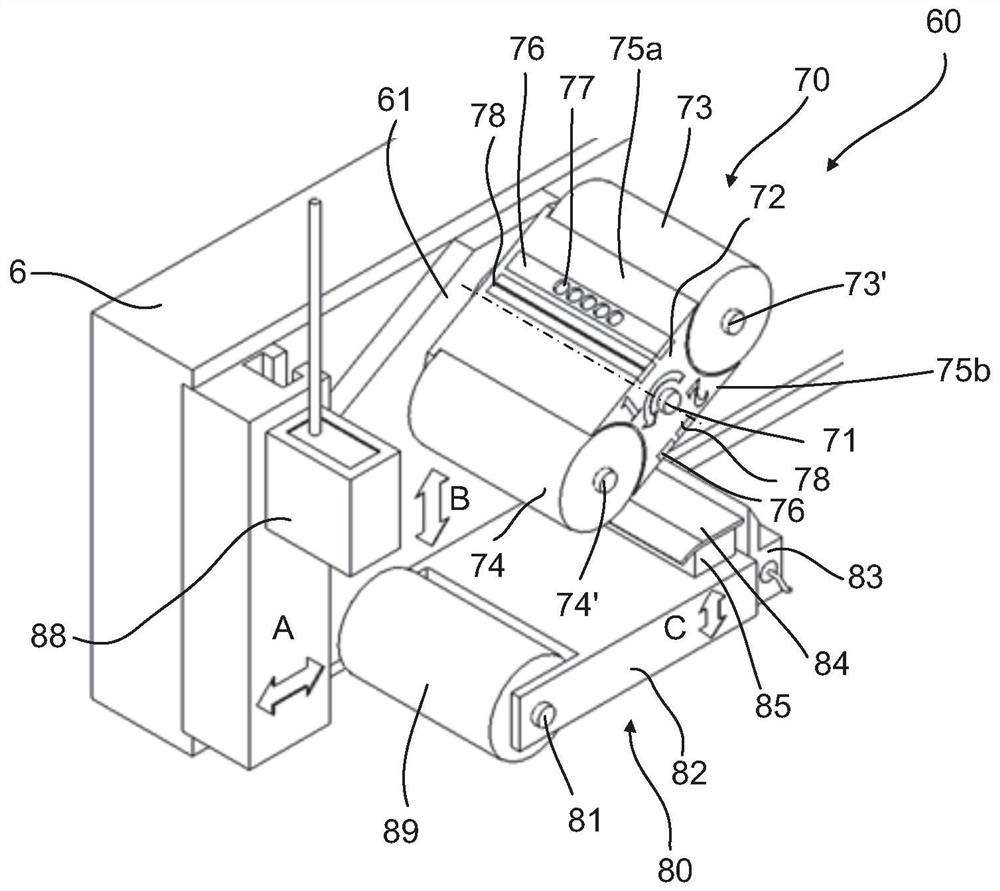

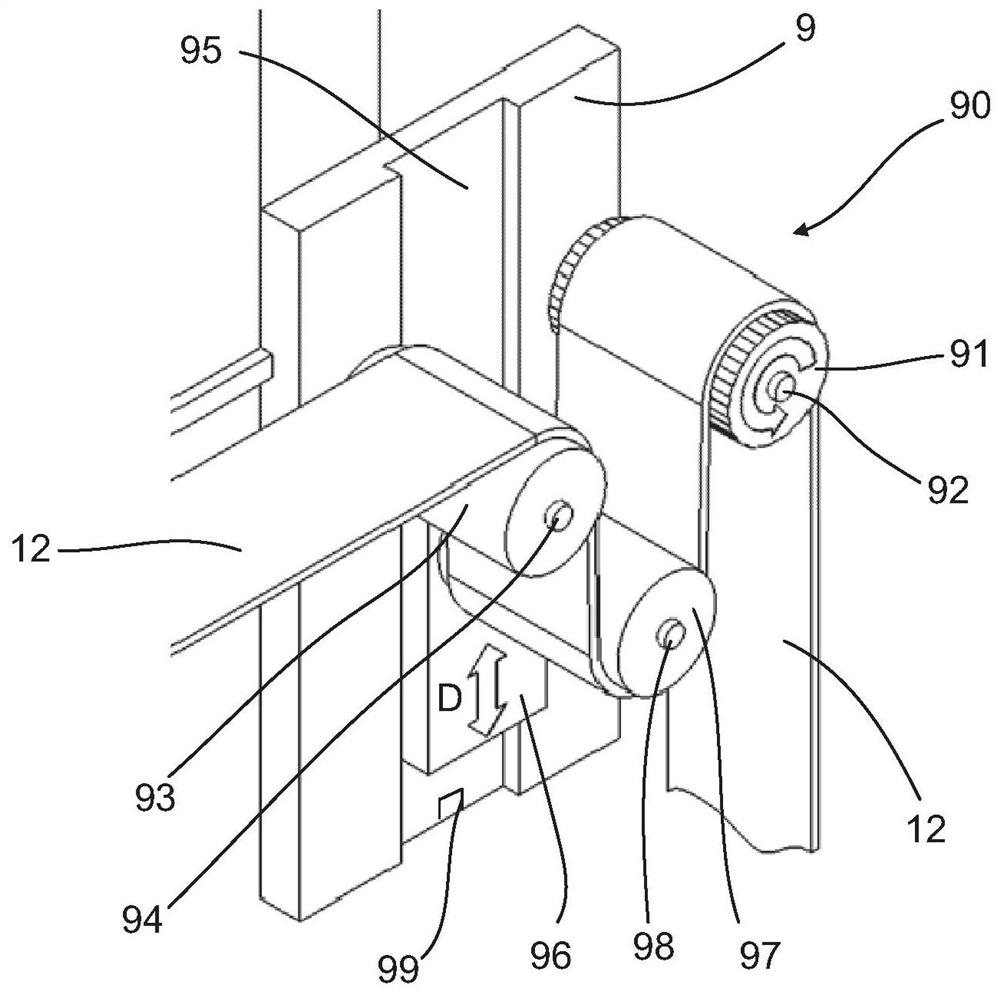

[0048] figure 1A strip laying device according to a first embodiment of the invention is shown. The device comprises means 3 for supporting the tread 2 and a frame 4 for supporting the components of the device. The mechanism 3 comprises a plurality of support rollers 5a, 5b, 5c mounted at a distance from each other and free to rotate about axes paral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com