Functional completeness testing platform and testing method for circuit board

A test platform and circuit board technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of single project and test circuit board not being universal, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the connector of the circuit board under test matches the connector of the test signal output unit of the circuit board under test and the output signal receiving unit of the circuit board under test.

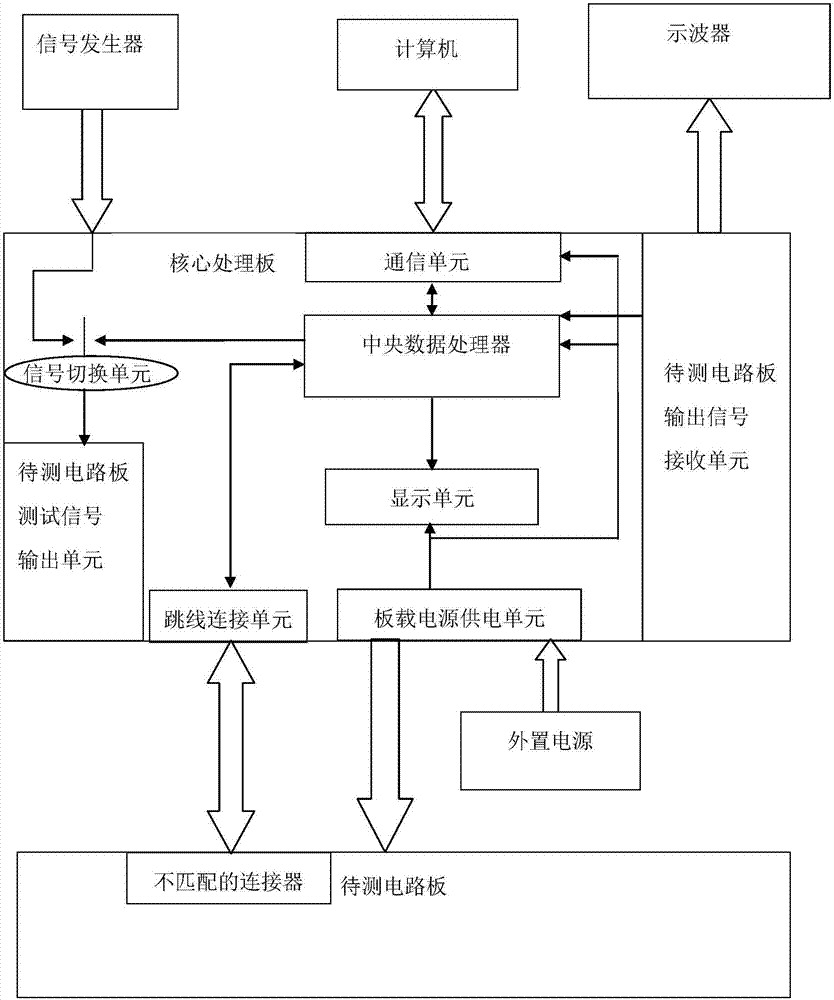

[0050] like figure 1 As shown, the circuit board functional integrity testing platform of the present embodiment includes: a core processing board, a computer, an external power supply, a signal generator and an oscilloscope; wherein, the core processing board includes a central data processor, a communication unit, a circuit board to be tested The test signal output unit, the output signal receiving unit of the circuit board under test, the signal switching unit, the display unit, the jumper connection unit and the onboard power supply unit; the external power supply is connected to the onboard power supply unit of the core processing board through a power cable The central data processor, communication unit and display unit of the circuit board to b...

Embodiment 2

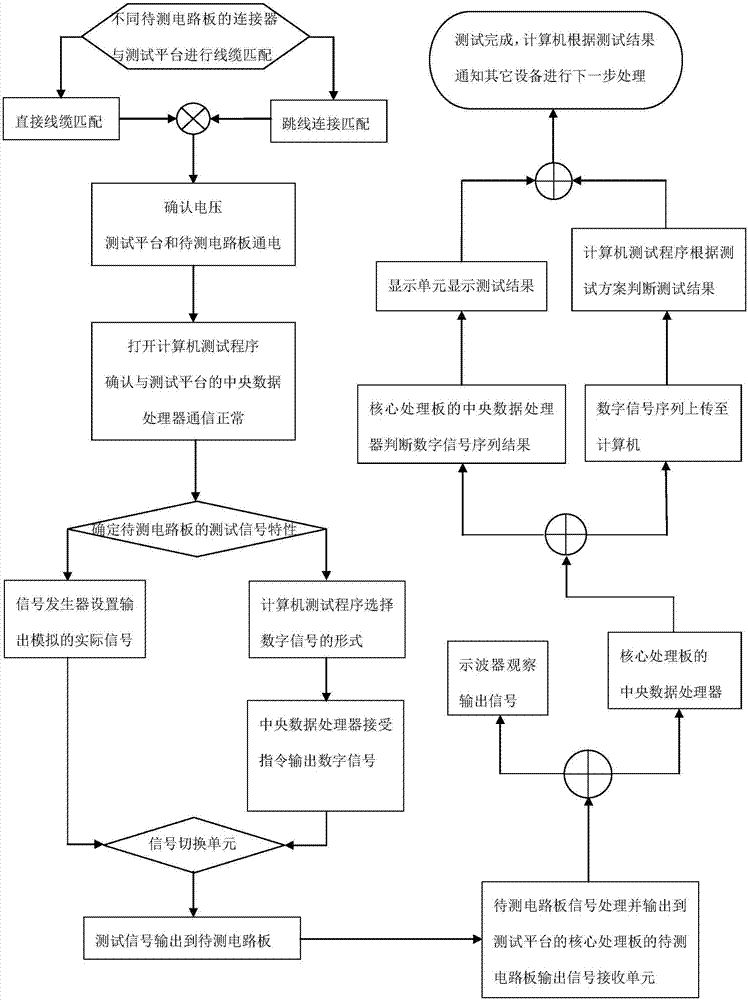

[0066] like image 3 As shown, the connector of the circuit board under test in this embodiment does not match the connector of the test signal output unit of the circuit board under test and the output signal receiving unit of the circuit board under test, and the circuit board under test is connected to the core processing unit through a jumper. on the jumper connection unit of the board; the central data processor sends a digital signal as a test signal, and the test signal is transmitted to the circuit board to be tested through the jumper connection unit. After the circuit board to be tested performs the test function, the output signal of the circuit board to be tested is transmitted to to the central data processor. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com