Diaphragm, preparation method and lithium ion battery comprising diaphragm

A separator and metal technology, used in the field of chemical power sources, can solve the problems of battery cycle performance, increased coating adhesion, and poor internal current consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

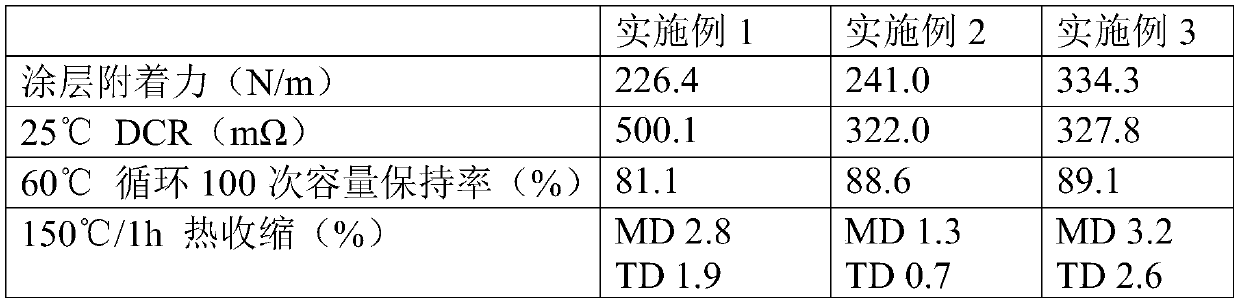

Embodiment 1

[0021] The gas-phase alumina powder particles with an average particle size of 30nm are configured into a suspension and injected into the atomizer. After the auxiliary gas enters the atomizer to bring out the small droplets of the suspension, it enters the nozzle area, and the plasma equipment has been activated. For discharge treatment, the nozzle will conduct plasma treatment on the PP substrate layer. Among them, the temperature of the atomizer is set at 80°C, the atmosphere is air, and the flow rate is 2L / min; the plasma discharge voltage is set at 500V, the discharge treatment is performed three times, and the moving speed of the nozzle is 500mm / min, and the pretreated PP with an intermediate layer is obtained. Substrate layer. Mix the alumina powder with a D50 lower than 5 μm and pure water evenly, prepare a suspension with a solid content of 30wt%, add a dispersant (AP) with a mass of 3% of the alumina powder, stir and disperse for 10 minutes, and add the oxide The ma...

Embodiment 2

[0023] The fumed alumina powder particles with an average particle size of 10nm are configured into a suspension and injected into the atomizer. After the auxiliary gas enters the atomizer to bring out the small droplets of the suspension, it enters the nozzle area, and the plasma equipment has been activated. For discharge treatment, the nozzle will conduct plasma treatment on the PE substrate layer. Among them, the temperature of the atomizer is set at 60°C, the atmosphere is air, and the flow rate is 1 L / min. The plasma discharge voltage was set to 230V, the discharge treatment was performed once, and the moving speed of the nozzle was 100mm / min to obtain a pretreated PE substrate layer with an intermediate layer. Mix alumina powder (D10 = 0.8 μm, D50 = 3.6 μm, D90 = 9.2 μm) with pure water, prepare a suspension with a solid content of 20 wt%, and add 1% dispersant to the mass of alumina powder , stirring and dispersing for 10 minutes, adding 1% polyacrylic acid binder by ...

Embodiment 3

[0025] The fumed alumina powder particles with an average particle size of 20nm are configured into a suspension and injected into the atomizer. After the auxiliary gas enters the atomizer to bring out the small droplets of the suspension, it enters the nozzle area, and the plasma equipment has been activated. For discharge treatment, the nozzle will conduct plasma treatment on the PE substrate layer. Among them, the temperature of the atomizer is set at 40°C, the atmosphere is air, and the flow rate is 0.5 L / min. The plasma discharge voltage was set to 100V, the discharge treatment was performed twice, and the nozzle moving speed was 200mm / min to obtain a pretreated PE substrate layer. Mix the alumina powder with a D50 lower than 2 μm and pure water evenly, prepare a suspension with a solid content of 10wt%, add 0.1% dispersant by mass of alumina powder, stir and disperse for 10 minutes, add mass of alumina powder 0.1% polyacrylate binder, after stirring and dispersing for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com