Semiconductor device lead assembling equipment

An assembly equipment and semiconductor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as missing insertion, reverse insertion, and prone to strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

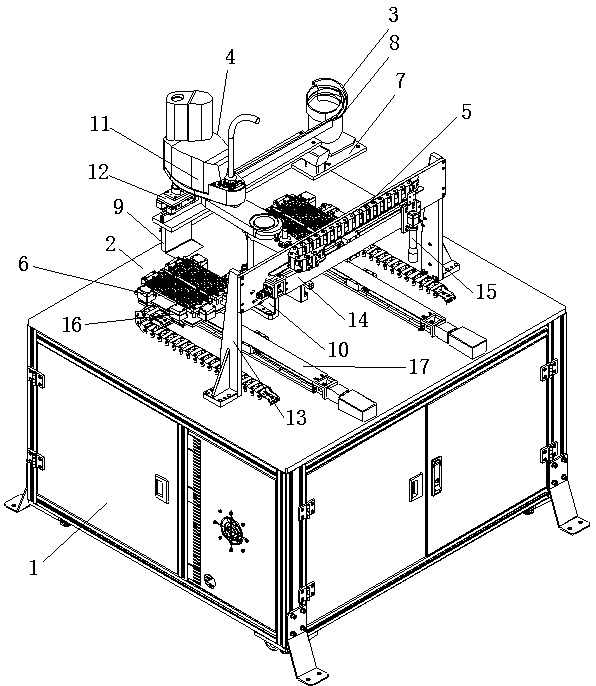

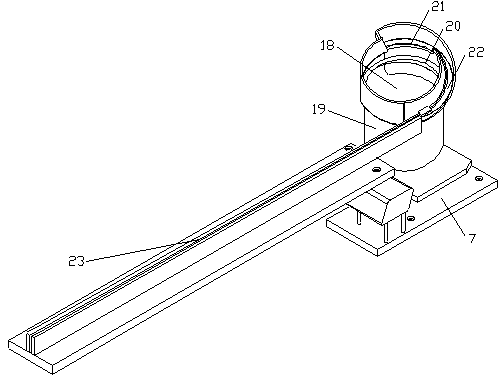

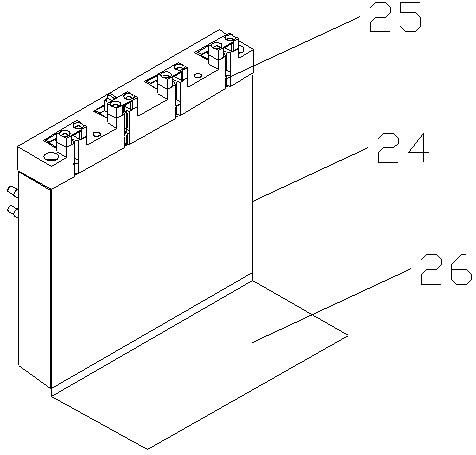

[0037] As a most basic embodiment of the present invention, this embodiment discloses a semiconductor device lead assembly equipment, such as figure 1 As shown, it includes a cabinet 1, and the cabinet 1 includes a work surface 2, and the work surface 2 is provided with a lead wire arrangement device 3, a lead wire grasping device 4, an eagle eye identification device 5 and a lead wire installation device 6, and the The lead wire arrangement device 3 includes a vibrating plate mounting base 7, a vibrating plate 8 and a jacking mechanism 9; the lead wire grabbing device 4 includes a manipulator mounting seat 10, a four-axis manipulator 11 and a lead wire grabbing mechanism 12; the eagle eye identification device 5 includes an eagle eye mounting frame 13, an eagle eye moving mechanism 14, and a CCD industrial camera 15; the lead wire installation device 6 includes a graphite box positioning plate mechanism 16 and a graphite box transmission mechanism 17; a PLC controller is arran...

Embodiment 2

[0040] As a preferred embodiment of the present invention, this embodiment discloses a semiconductor device lead assembly equipment, such as figure 1 As shown, it includes a cabinet 1, and the cabinet 1 includes a work surface 2, and the work surface 2 is provided with a lead wire arrangement device 3, a lead wire grasping device 4, an eagle eye identification device 5 and a lead wire installation device 6, and the The lead wire arrangement device 3 includes a vibrating plate mounting base 7, a vibrating plate 8 and a jacking mechanism 9; the lead wire grabbing device 4 includes a manipulator mounting seat 10, a four-axis manipulator 11 and a lead wire grabbing mechanism 12; the eagle eye identification device 5 includes an eagle eye mounting frame 13, an eagle eye moving mechanism 14, and a CCD industrial camera 15; the lead wire installation device 6 includes a graphite box positioning plate mechanism 16 and a graphite box transmission mechanism 17; a PLC controller is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com