Disc base structure of washing machine and washing machine with disc base structure

A washing machine and tray base technology, applied in the field of washing machines, can solve the problems of taking up too much space and increasing the single washing capacity of the washing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

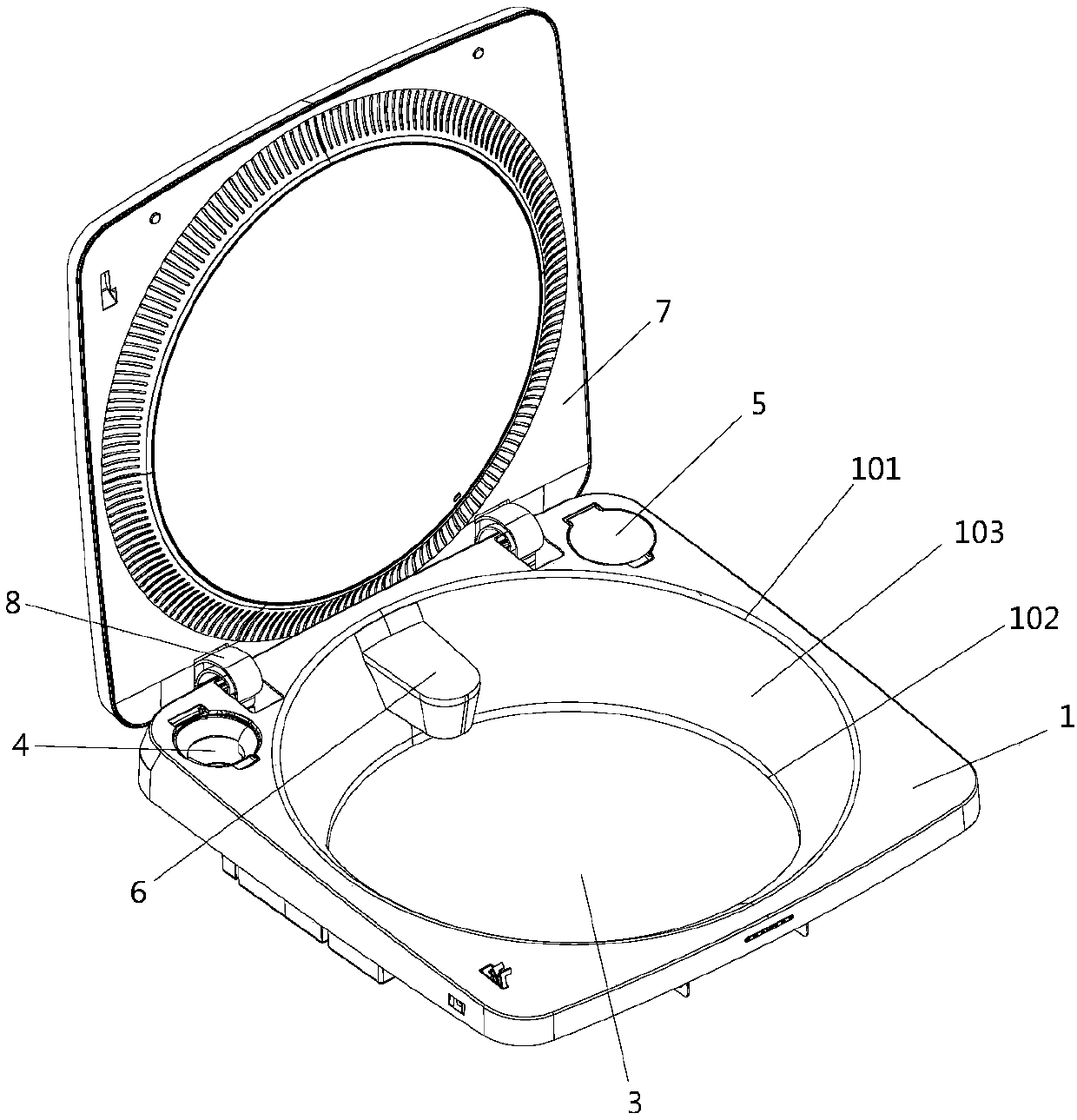

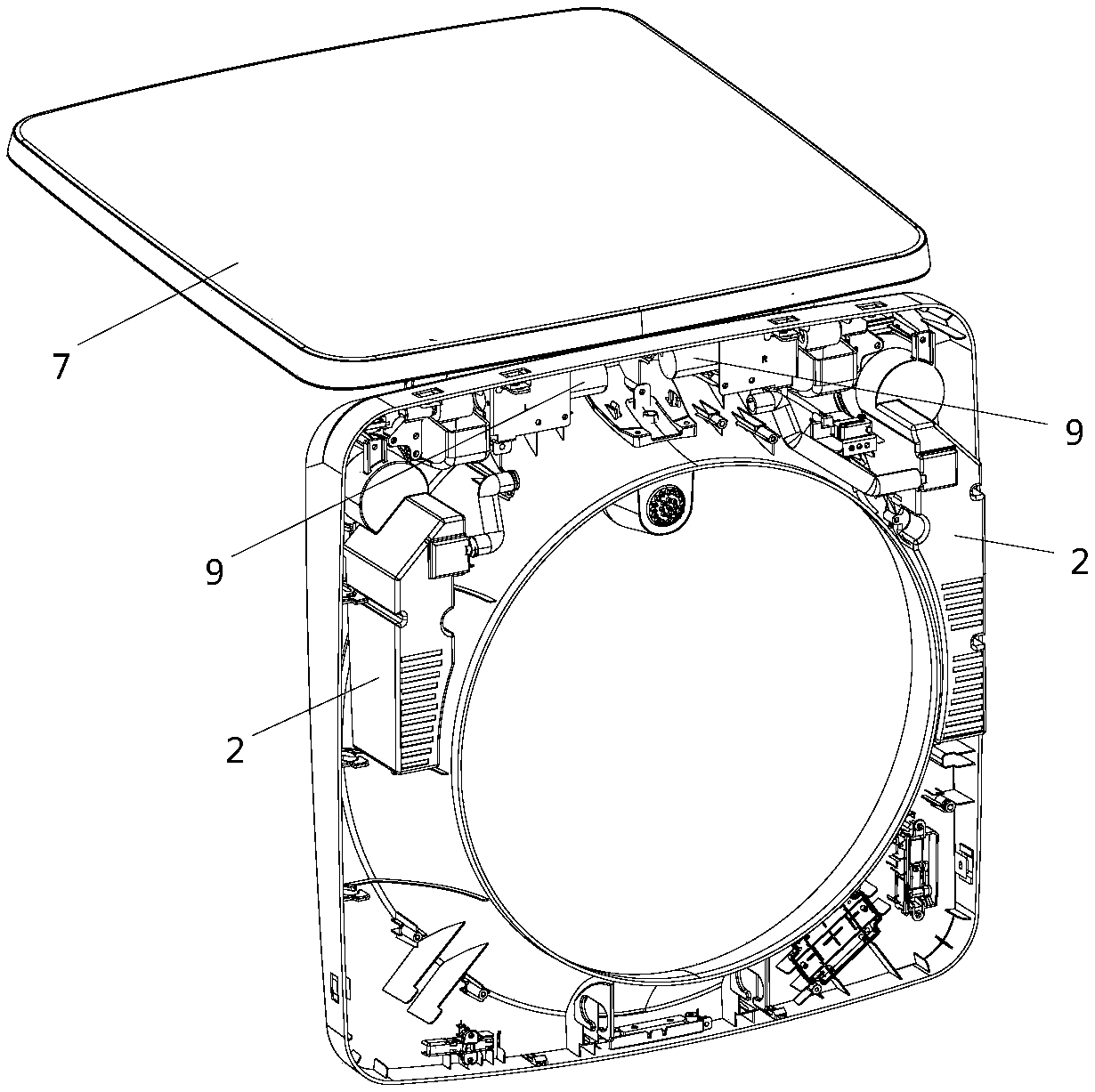

[0060] Such as figure 1 and figure 2 As shown, the structure of the tray base 1 of a washing machine described in this embodiment includes an upper cover 7, which is arranged correspondingly to the shape of the tray base 1, and is set to open or close the clothes insertion port 3; the clothes insertion port 3 is approximately circular, and is set On the tray base 1, it is arranged to put clothes on, and the shape described in this embodiment is correspondingly arranged, and the upper cover 7 can at least completely cover the tray base 1 when fastened. In the existing washing machine, the upper cover 7 is usually fastened and connected with the disc base 1, but because components such as a control board need to be provided, a part of the space of the upper cover 7 is usually set as a control board and other components, and connected with the disc base 1, This kind of setting has caused that the upper cover 7 needs to cooperate with the control panel to cover the entire tray b...

Embodiment 2

[0063] Such as figure 1 and figure 2 As shown, this embodiment is a further limitation of the first embodiment above. The structure of the tray base 1 of the washing machine described in this embodiment includes an accommodating chamber 2, which is arranged inside the tray base 1 to accommodate additives; 3. It is set on the disc base 1 and is set to put clothes in; the upper cover 7 is connected with the disc base 1 through a pivot 8 and is set to open or close the clothes feeding port 3; at least two of the additive feeding ports 4 are arranged on the disc base 1. In the area defined between the adjacent side walls and the clothes delivery port 3, and communicated with the accommodating chamber 2; the ultrasonic cleaning module 6 is arranged at the clothes delivery port 3 between two adjacent additive delivery ports 4. In this embodiment, an additive injection port 4 communicating with the accommodating chamber 2 is provided in the area defined between the adjacent side wa...

Embodiment 3

[0066] Such as figure 1 and figure 2 As shown, this embodiment is a further limitation of the above-mentioned embodiment 1 or embodiment 2. The structure of the tray base 1 of the washing machine described in this embodiment includes a clothes insertion port 3 arranged on the tray base 1 for putting clothes into It is connected with the disk base 1 through a pivot 8, and is used to open or close the upper cover 7 of the clothing insertion port 3; Throw in outlet 102; Put in between inlet 101 and throw in outlet 102, be connected by smooth curved surface 103; Smooth curved surface 103 is provided with described ultrasonic cleaning module 6; The distance from the center of the outlet 102 is smaller than the distance from its projection on the plane where the delivery inlet 101 is located to the center of the delivery inlet 101 .

[0067] In the present invention, the additive feeding port 4 is provided in the area formed by the two side walls of the disc seat 1 and the clothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com