Automatic peeling device for lower part of mulberry fork

An automatic, rotating shaft technology, applied to bark, wood processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

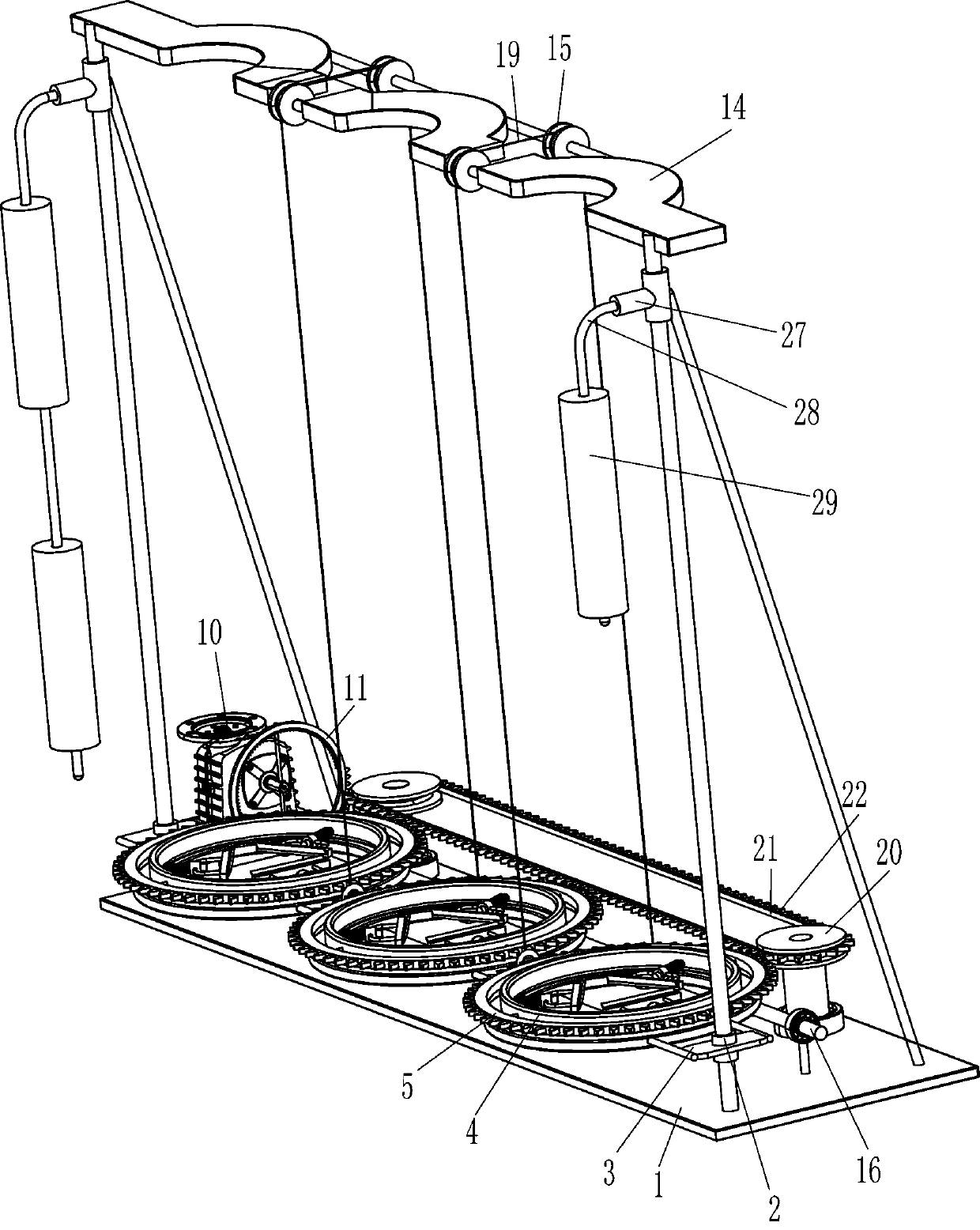

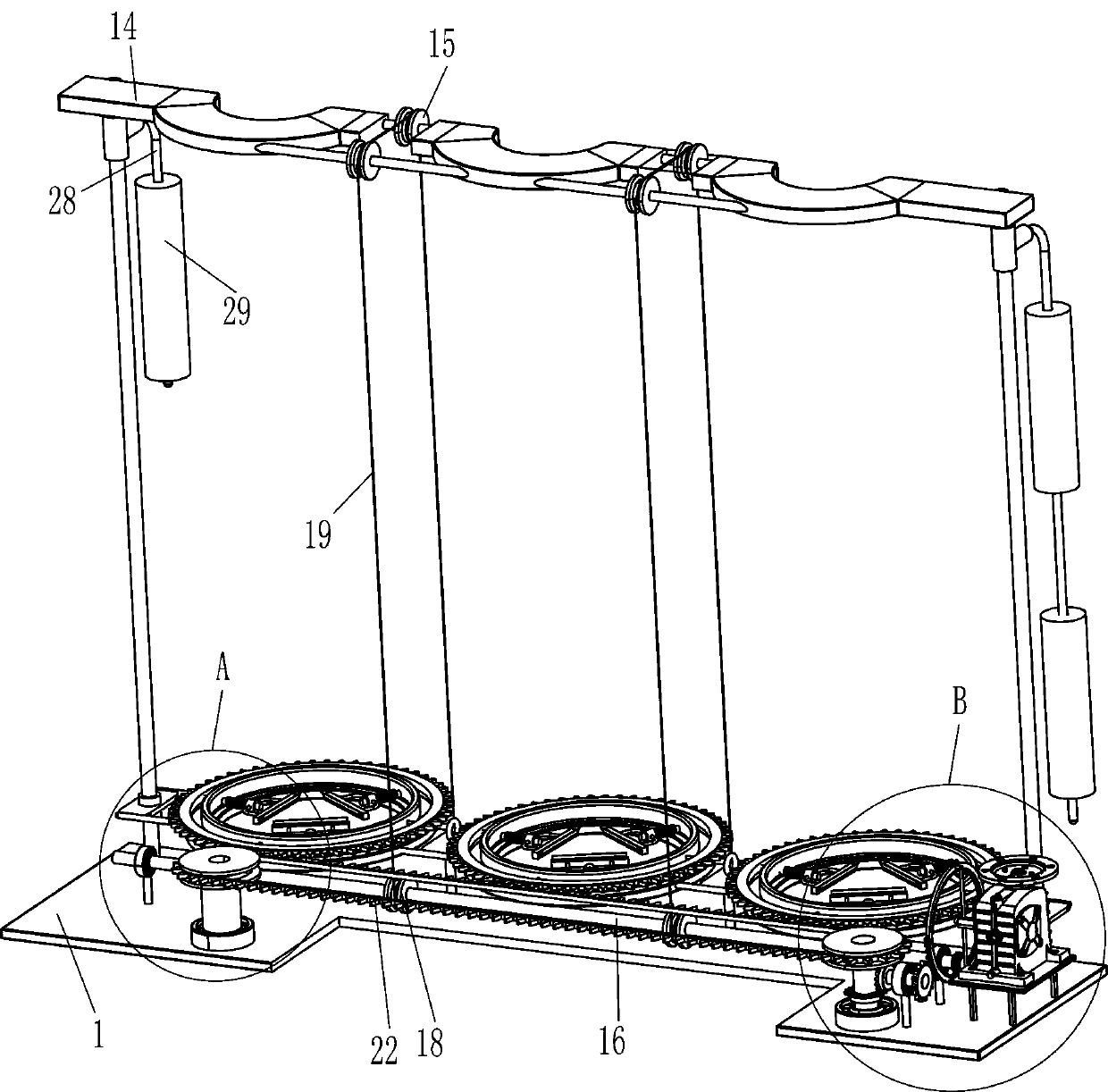

[0021] An automatic peeling device for the lower part of a mulberry fork, such as Figure 1-5 As shown, it includes a support 1, a scraping assembly, a power assembly, a top plate 14, a lifting assembly and a transmission assembly. The support 1 is provided with a scraping assembly that scrapes the skin through a blade, and the support 1 is provided with a power supply powered by a motor. Assemblies, the top of the support 1 is provided with a top plate 14, the top plate 14 and the support 1 are provided with a lifting assembly for lifting by pulling, and the support 1 is provided with a transmission assembly for transmission by rotation.

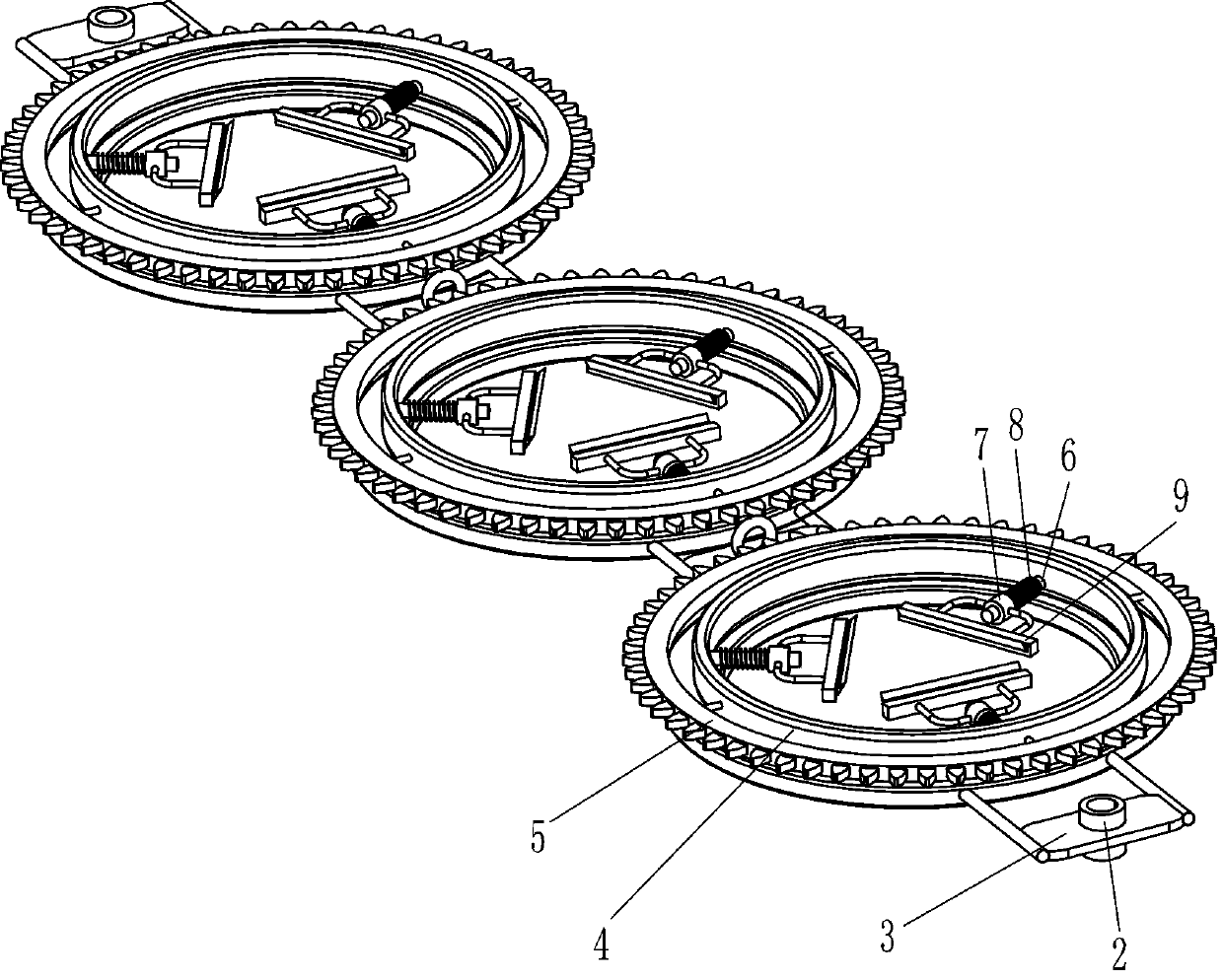

[0022] like figure 2 As shown, the skin scraping assembly includes a sliding sleeve 2, a lifting plate 3, an annular plate 4, a ring gear 5, a guide rod 6, a guide sleeve 7, a compression spring 8 and a scraper 9, and the front and rear sides of the bracket 1 are slidingly equipped with Sliding sleeve 2, there is a lifting plate 3 between...

Embodiment 2

[0032] like figure 1As shown, on the basis of Embodiment 1, in order to make the equipment more stable, it also includes a rotary joint 27, a swing rod 28 and a rubber roller 29. Formula is provided with fork 28, and fork 28 tail ends are all provided with rubber roller 29.

[0033] The working principle of the above embodiment: After placing the mulberry fork, push the swing lever 28 to swing upward, drive the rubber roller 29 to swing upward, fix the mulberry fork, and pull the swing lever 28 to swing downward when the mulberry fork needs to be taken out Reset, drive rubber roller 29 to swing downwards and reset, like this, can carry out stable fixation with mulberry fork, have prevented the mulberry fork top from shifting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com