Full-automatic riveting production line

A production line, fully automatic technology, applied in the field of mechanical processing, can solve the problems of inconvenient operation, large project, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

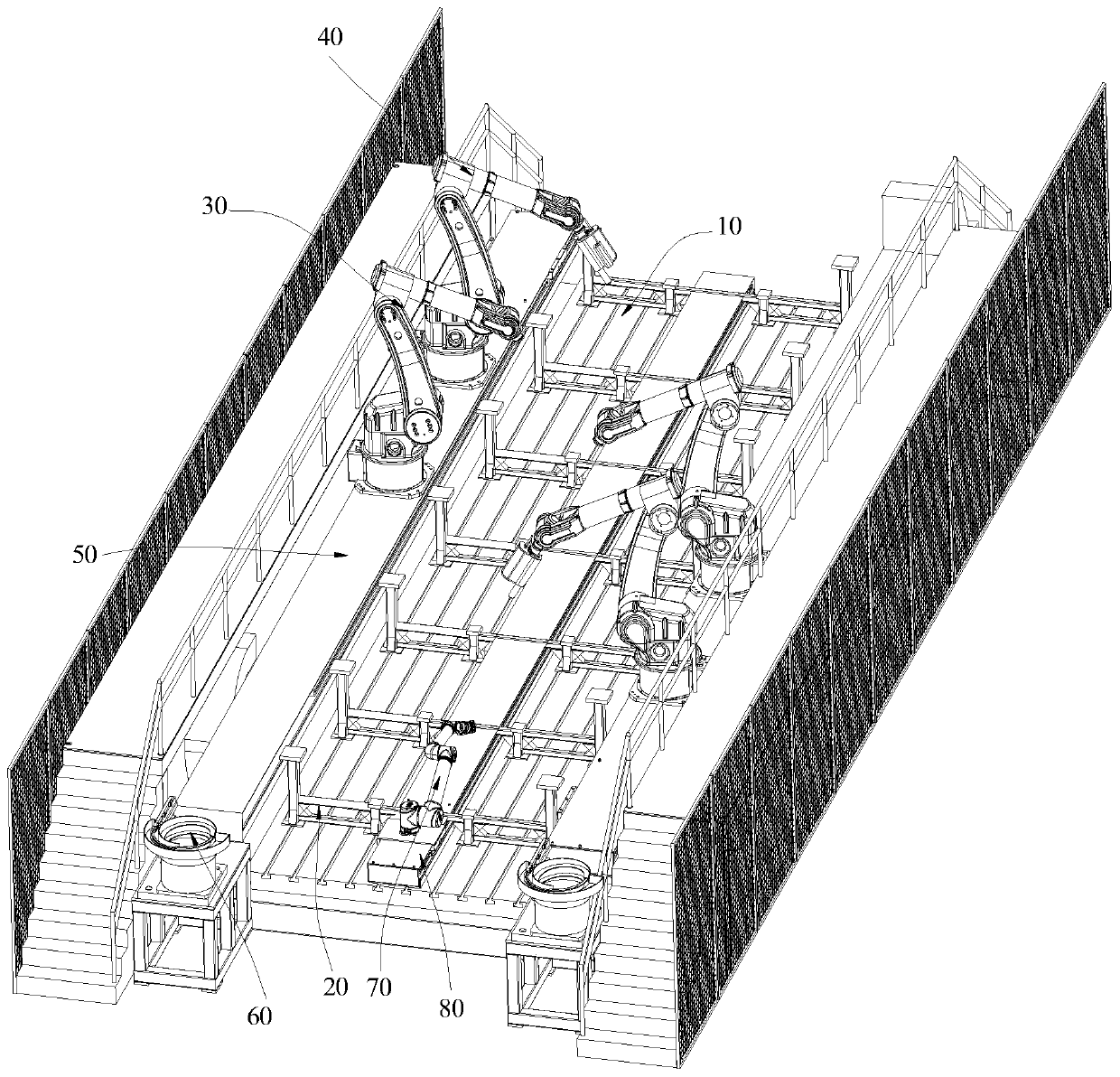

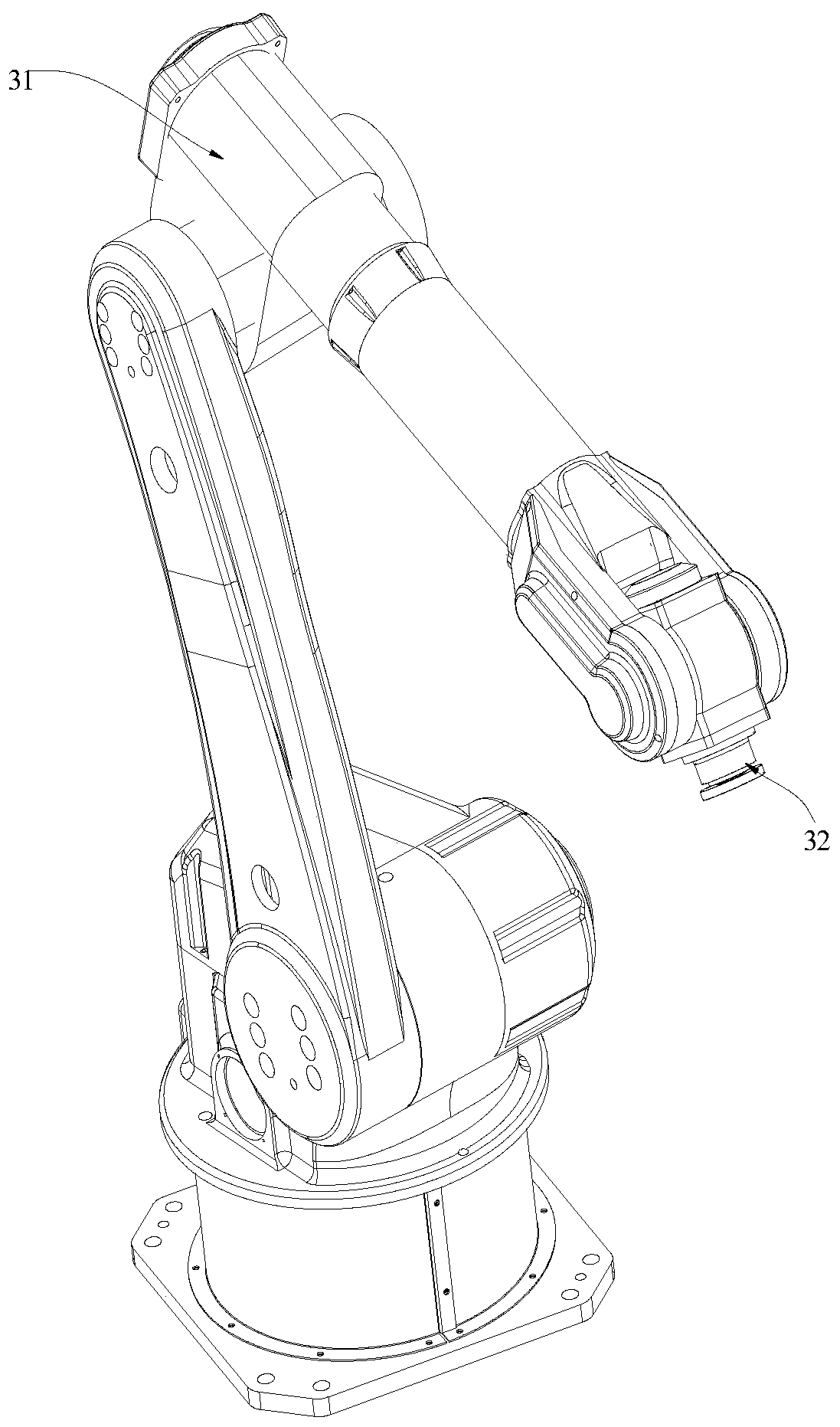

[0028] like Figure 1-6 A fully automatic riveting production line shown includes a body 10, a riveting robot 30, a punching mechanism 40, and a first drive mechanism 50. A support assembly is provided on the body 10, and the support assembly includes at least two support frames 20, the support frame The top end of 20 is formed as a supporting surface, and at least two supporting surfaces are used to support workpieces. Specifically, the above-mentioned punching mechanism 40 can punch holes on the workpiece, and the riveting robot 30 is used to grip the rivets and rivet them into the holes of the workpiece. Driven by the first driving mechanism 50 , both the riveting robot 30 and the punching mechanism 40 can move along a conveying direction.

[0029] On the basis of the above structure, when using the automatic riveting production line of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com