Device and method for preparing ultrafine grains from difficult-to-deform material

A preparation device and ultra-fine crystal technology, applied in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

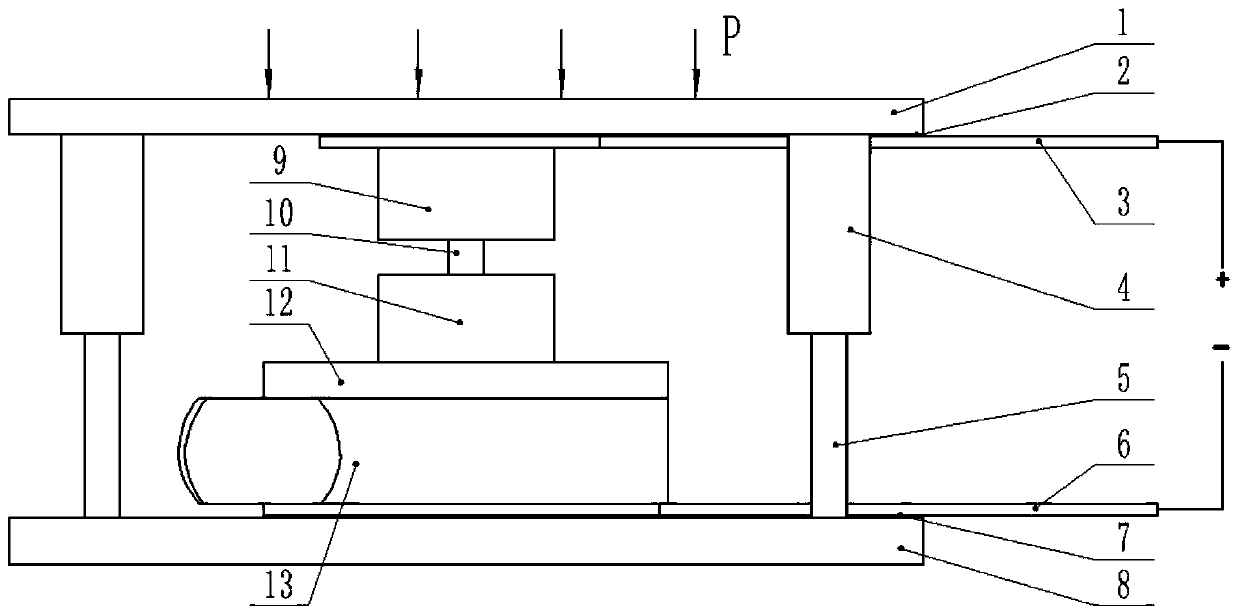

[0029] see figure 1 A device for preparing ultra-fine crystals of difficult-to-deform materials, including a mold assembly, a loading device, a control system and a power supply system thereof, the mold assembly is installed in the loading device and connected to the power supply device, and the loading device is also connected to the control system.

[0030] The mold assembly includes an upper mold 9 assembly and a lower mold 11 assembly, and the upper mold 9 assembly includes an upper mold 9 plate 1, an upper insulating plate 2, an upper copper electrode 3 and an upper mold 9 arranged in sequence from top to bottom;

[0031] The lower mold 11 assembly includes the lower mold 11 plate 8, the lower insulating plate 7, the lower copper electrode 6, and the lower mold 11 arranged in sequence from bottom to top, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com