Micromechanical presssure sensor device and corresponding production method

一种压力传感器、微机械的技术,应用在测量流体压力、通过电磁元件测量流体压力、仪器等方向,能够解决压力传感器设备性能变差等问题,达到有效机械解耦、简单密封连接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

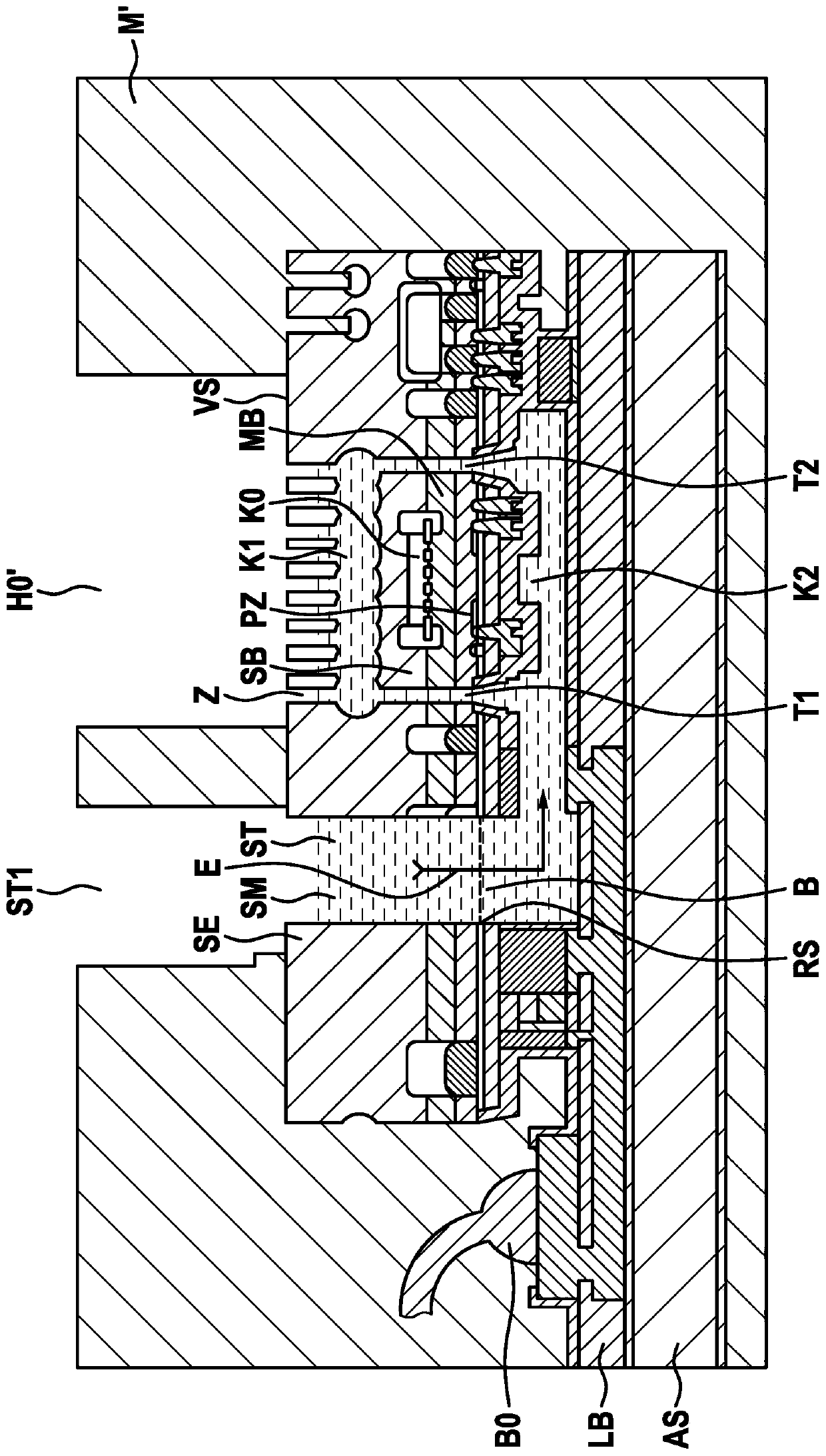

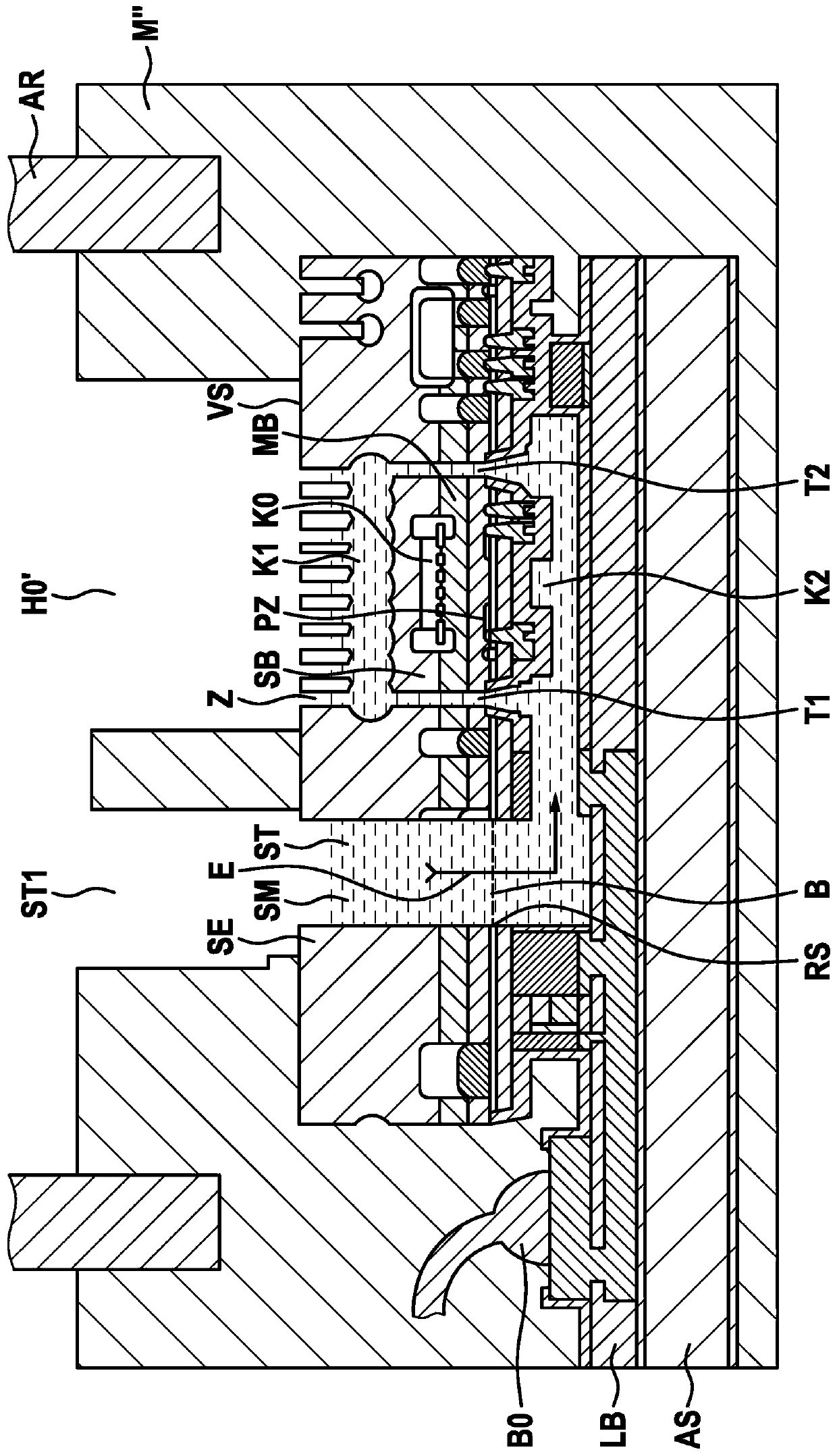

[0025] In the figures, identical reference numbers indicate identical or functionally identical elements.

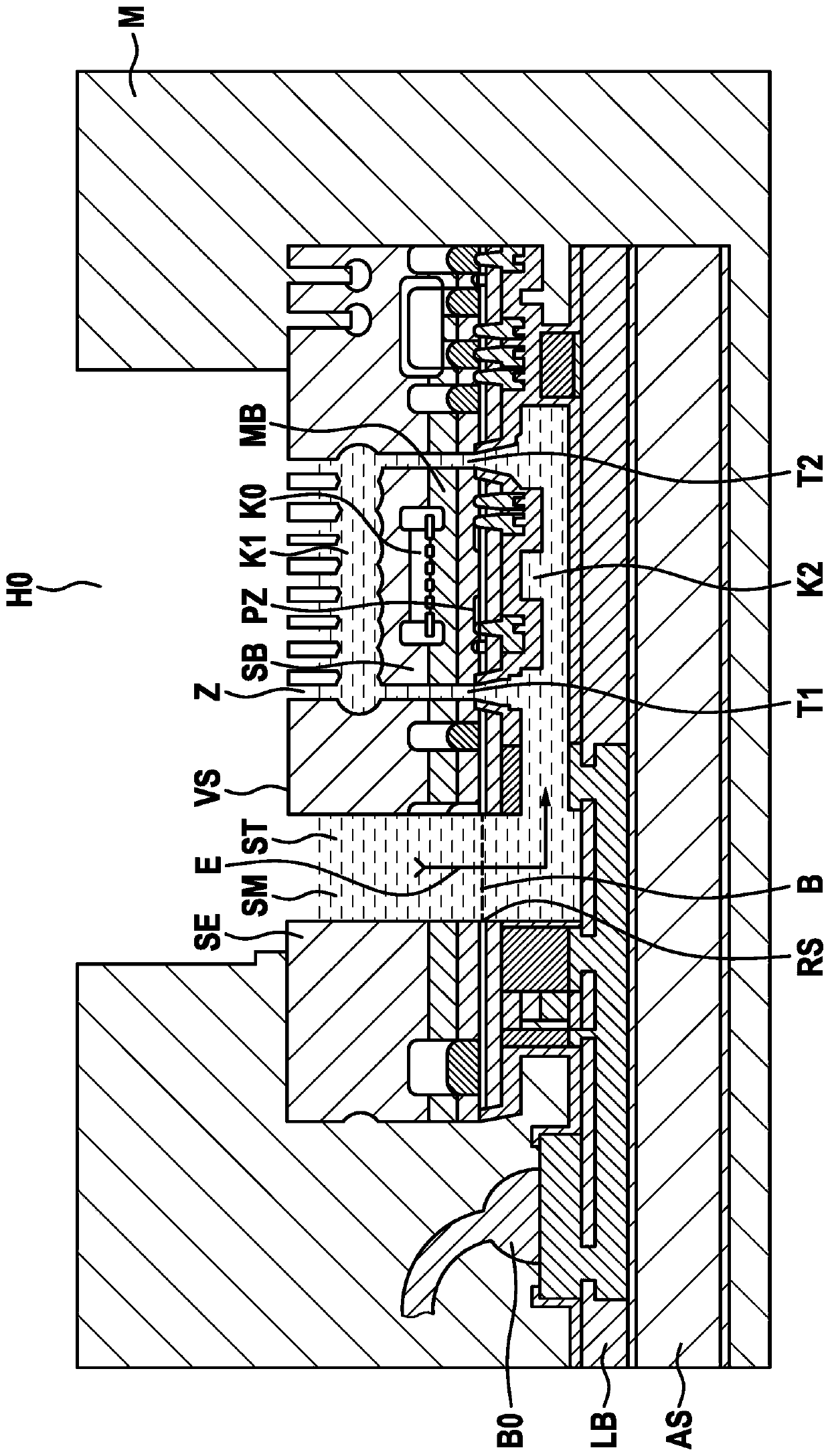

[0026] figure 1 A schematic cross-sectional illustration of a micromechanical pressure sensor device according to a first embodiment of the invention is shown.

[0027] exist figure 1 , the reference SE indicates a sensor substrate with a front side VS and a back side RS. The pressure sensor arrangement SB is suspended in the substrate. In the present embodiment, the suspension is realized by conductor tracks (not shown) in the sensor substrate SE, but may optionally or alternatively be realized by webs of the substrate material, for example silicon.

[0028] A first chamber K1 is arranged in the sensor substrate SE above the pressure sensor arrangement SB, which first chamber emerges through a plurality of access openings Z toward the front side VS.

[0029] The pressure sensor arrangement SB suspended in the sensor substrate SE is surrounded by a plurality of stres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com