Method for preparing TEM sample through FIB reverse cutting

A sample and sample stage technology, which is applied in the field of back-cut preparation of TEM samples by focused ion beam, can solve the problems of inconsistent thickness of TEM samples, judging sample thickness, and unfavorable semiconductor device layer analysis, etc., so as to improve the preparation efficiency of back-cut samples and reduce the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

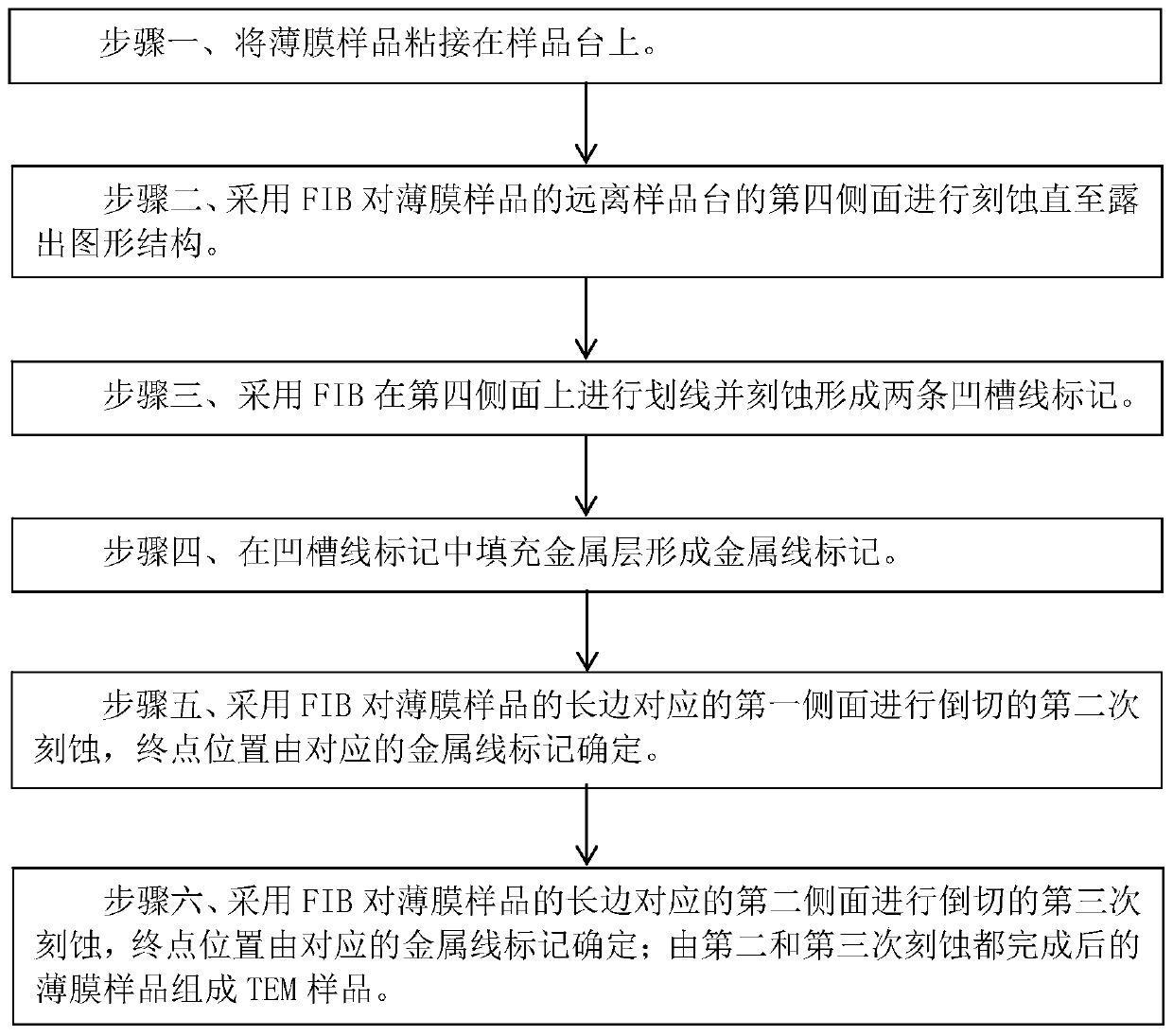

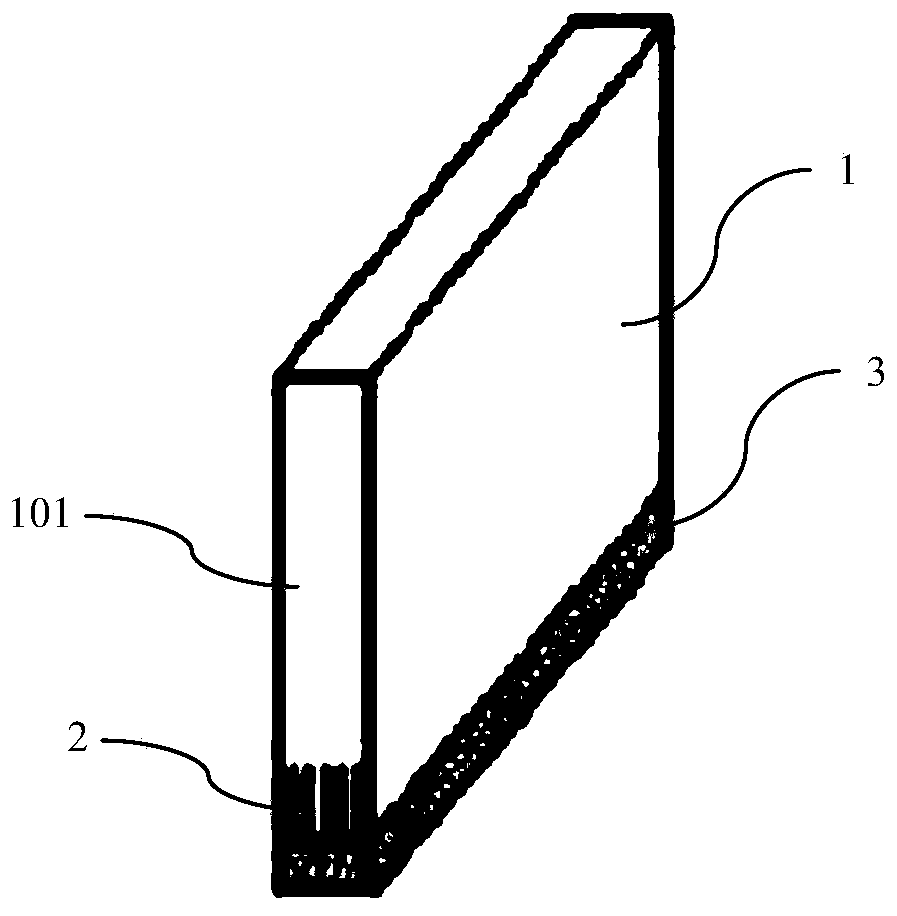

[0036] Such as figure 1 Shown is the flowchart of the method for preparing a TEM sample by FIB downcutting in an embodiment of the present invention; as Figure 2A to Figure 2H Shown is the three-dimensional structural diagram of the thin film sample in each step of the method of the embodiment of the present invention; Figure 3A-Figure 3H yes Figure 2A-Figure 2H Corresponding enlarged structural diagram; the method for preparing TEM sample by FIB in the embodiment of the present invention comprises the following steps:

[0037] Step one, such as Figure 2A As shown, the corresponding magnified figure is Figure 3A, the thin film sample is bonded on the sample stage of the dual-beam system with FIB and electron beam, the thin film sample includes a semiconductor substrate 1, a semiconductor device layer 2 with a pattern structure formed on the front side of the semiconductor substrate 1 and a protective layer 3. The film sample has a cuboid structure, the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com