Calibration method for rapidly determining geometric position of each part in deflection measurement system

A technology of measurement system and calibration method, which is applied in the field of optical engineering and can solve problems such as the inability to directly determine the position of a workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

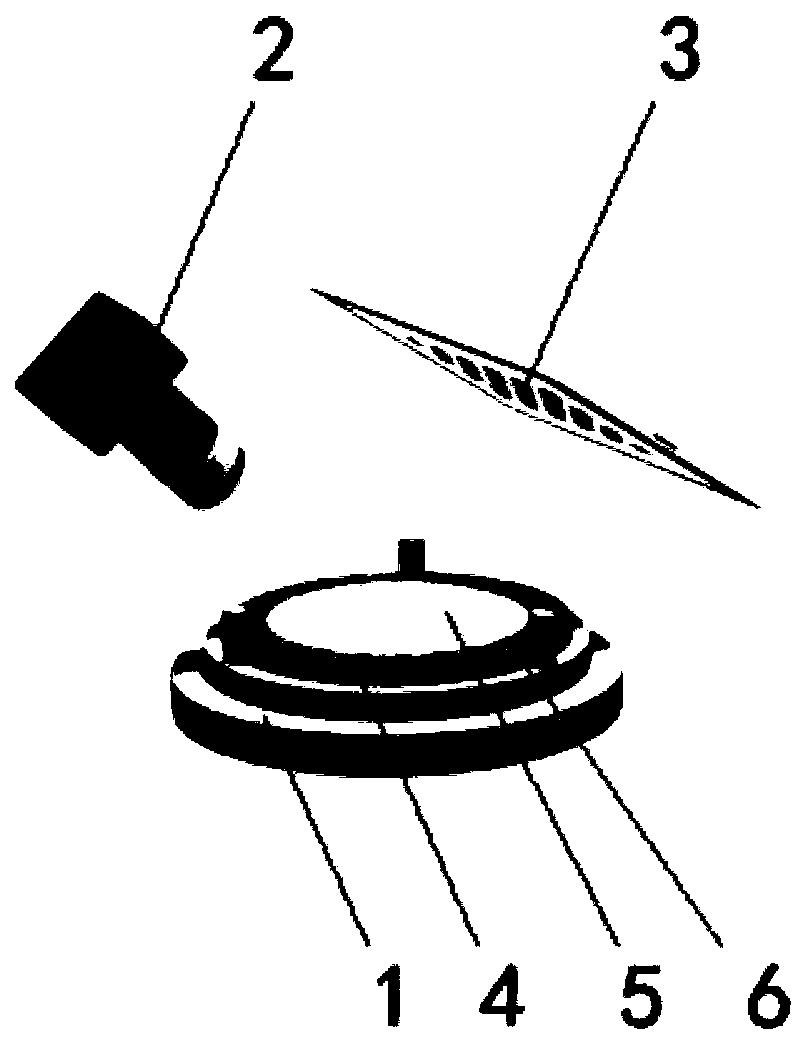

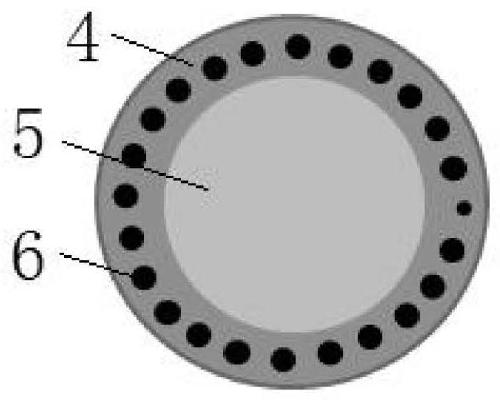

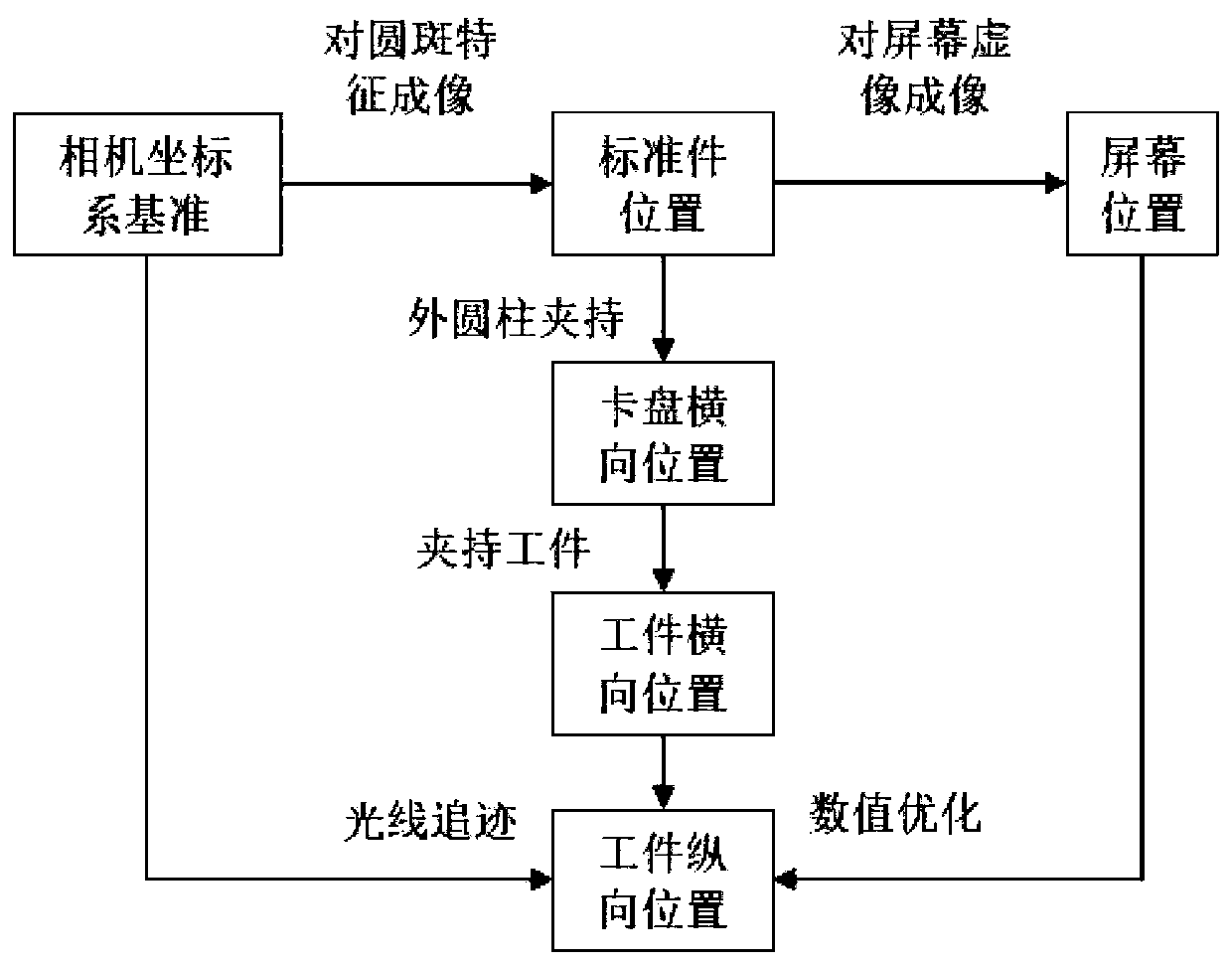

[0039] In order to realize the quick and simple calibration of the deflection measurement system, the ordinary flat mirror is made into a standard part with its own reference for improvement. It is made of aluminum alloy, and the upper part is a cylinder with a diameter of 200mm and a height of 10mm. The upper surface is made of single-point diamond. Turned into a mirror surface, the flatness is better than λ / 5PV. Process 24 circular spots with a diameter of 16mm evenly distributed on the upper surface at φ180mm, one of which is set to a diameter of 10mm, and all the circular spots are blackened, such as figure 1 shown. The pose of the plane mirror is obtained directly through the landmark points on the plane mirror. The screen displays a 20×15 dot array, and the diameter of each dot is set to 15 pixels, according to image 3 Steps to complete the geometric calibration. Measure an aspherical workpiece with a caliber of 130mm, and perform ray tracing from the center of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com