Fireproof titanium alloy door and using method thereof

A technology for fire doors and titanium alloys, applied in the field of fire doors, can solve the problems of easy atomization of glass, proven fire, and unclear visibility, etc., to achieve the effects of easy viewing of fire, convenient operation, and slowing down the speed of destruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

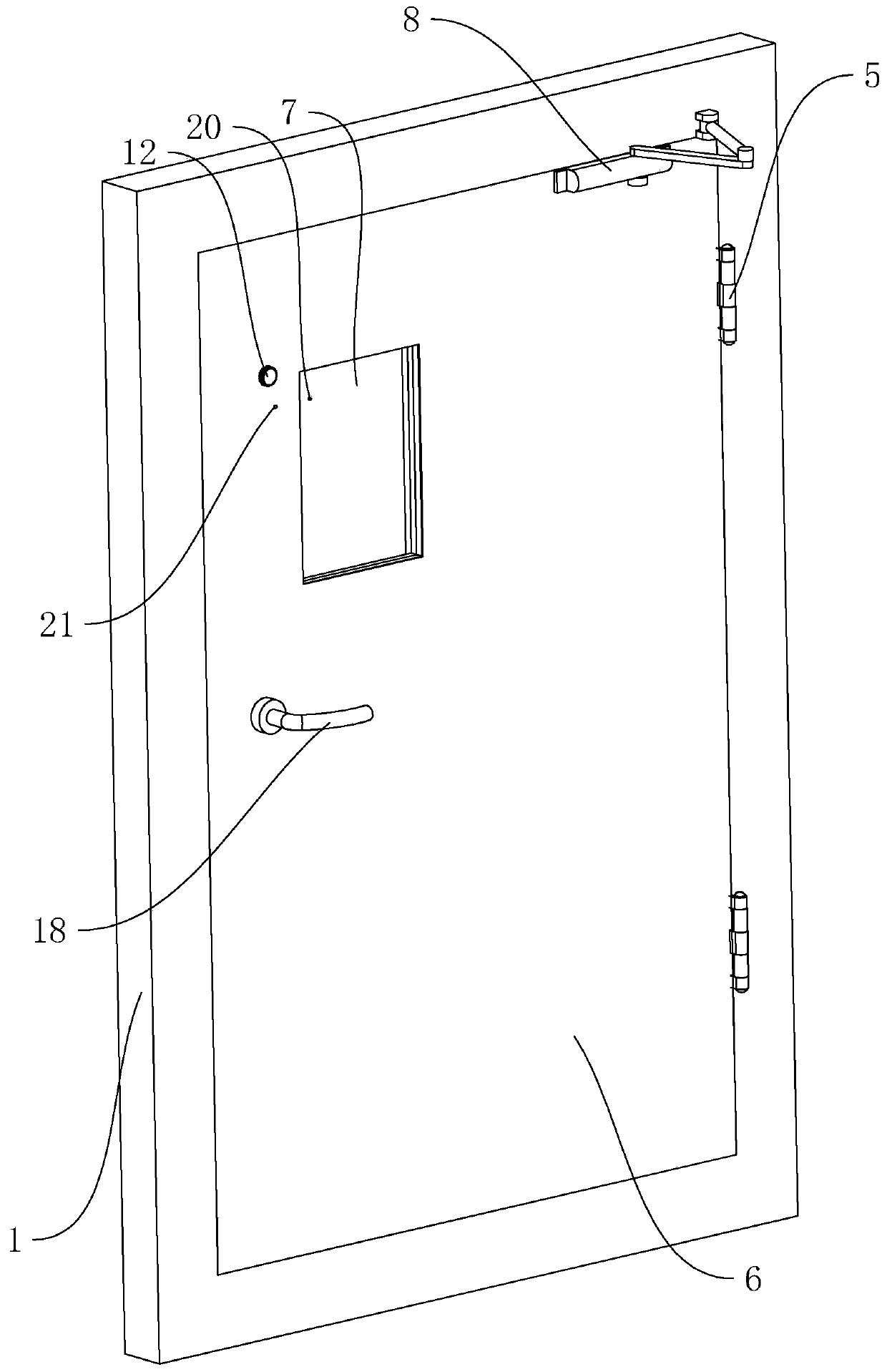

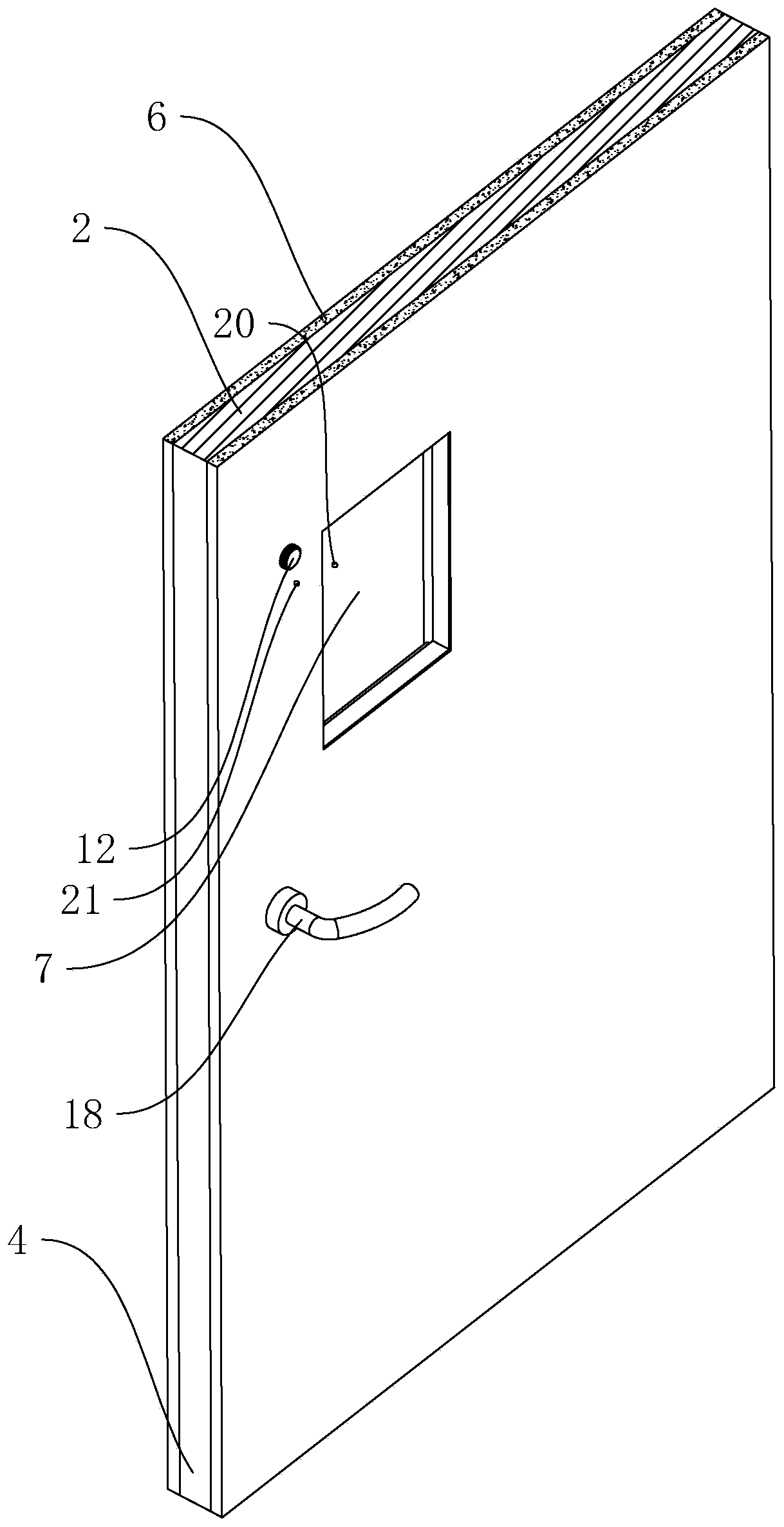

[0045] Embodiment 1, with reference to figure 1 , is a titanium alloy fireproof door disclosed by the present invention, comprising a door frame 1, a door body 4 is embedded in the door frame 1, one side of the door body 4 is hinged on the inner side of the door frame 1 through a hinge 5, and the upper part of the door body 4 A window (not shown) is provided at the position, and an observation window 7 is installed on the window. The size of the observation window 7 is 20cm*60cm, and a handle 18 is fixedly installed in the middle of the front and back sides of the door body 4, so as to facilitate the installation of the door body. 4 on and off. A door closer 8 for driving the door body 4 to open and close is fixedly installed between the door body 4 and the door frame 1 . The model of the door closer 8 is PT-602.

[0046] refer to figure 2 , the door body 4 is filled with a fireproof core board 2, the fireproof core board 2 has fireproof performance, and the front and back...

Embodiment 2

[0080] Embodiment 2, a method for using a titanium alloy fire door, comprising the following steps:

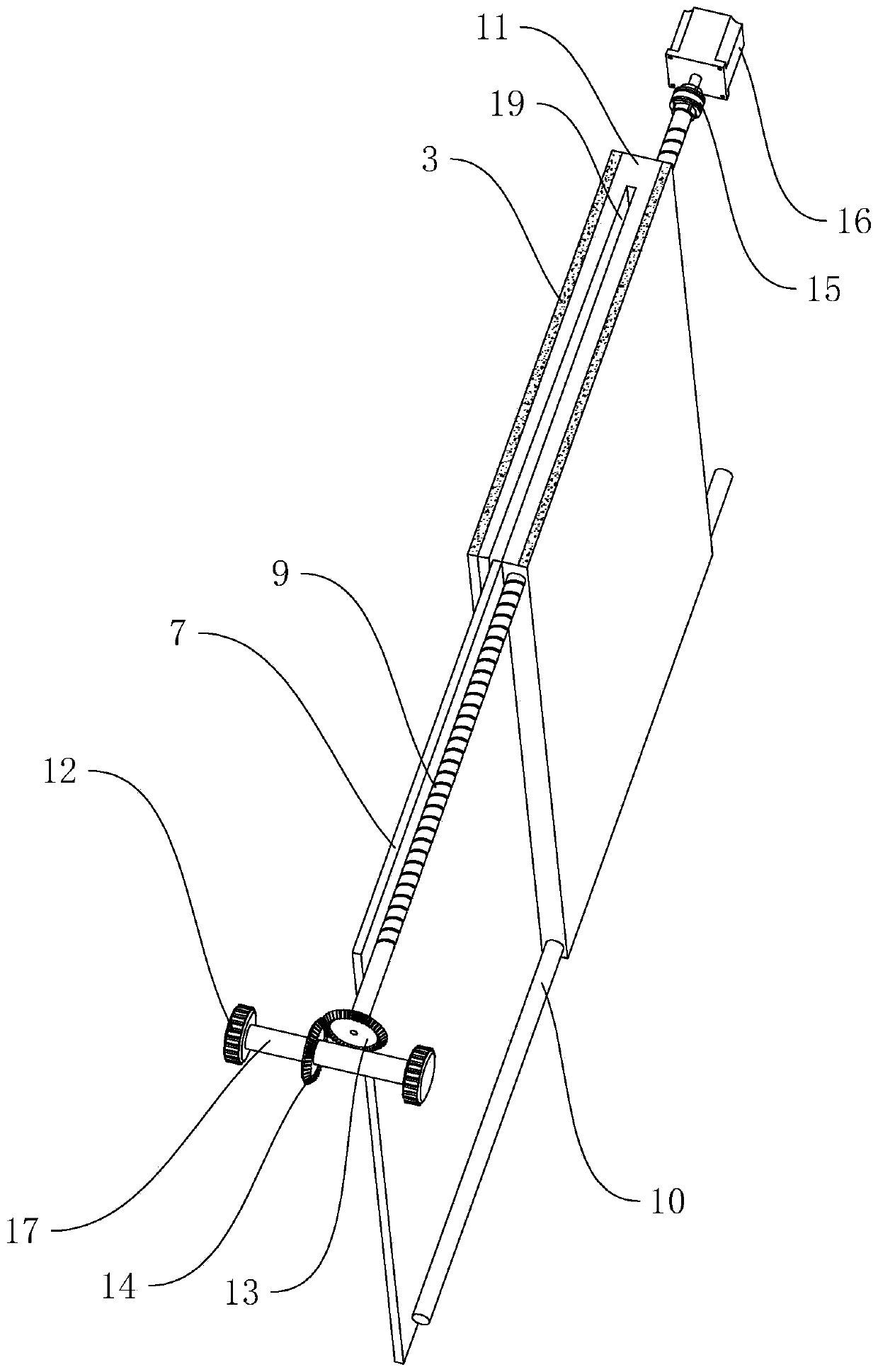

[0081] When a fire breaks out, the micro-controller receives the feedback signal, inputs an electrical signal to the power terminal of the dimming glass, controls the power terminal of the dimming glass to start, and the observation window 7 becomes transparent, and at the same time, the detection unit monitors the humidity of the observation window 7 Value, the temperature sensor 21 monitors the temperature value of the door body 4;

[0082] When the humidity of the observation window 7 exceeds the preset value, the detection unit inputs an electric signal to the microcontroller to control the cleaning mechanism to scrub the glass of the observation window 7 until the humidity value of the glass of the observation window 7 meets the preset condition, and the microcontroller The device controls the cleaning mechanism to be completely stored in the door body 4, and the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com