Steering lifting moving platform

A technology for transferring and lifting cylinders, which is applied to the parts and packaging of strapping machinery, which can solve the problems of dumping, long running time, and low efficiency, and achieve the effects of stable use, sensitive steering, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

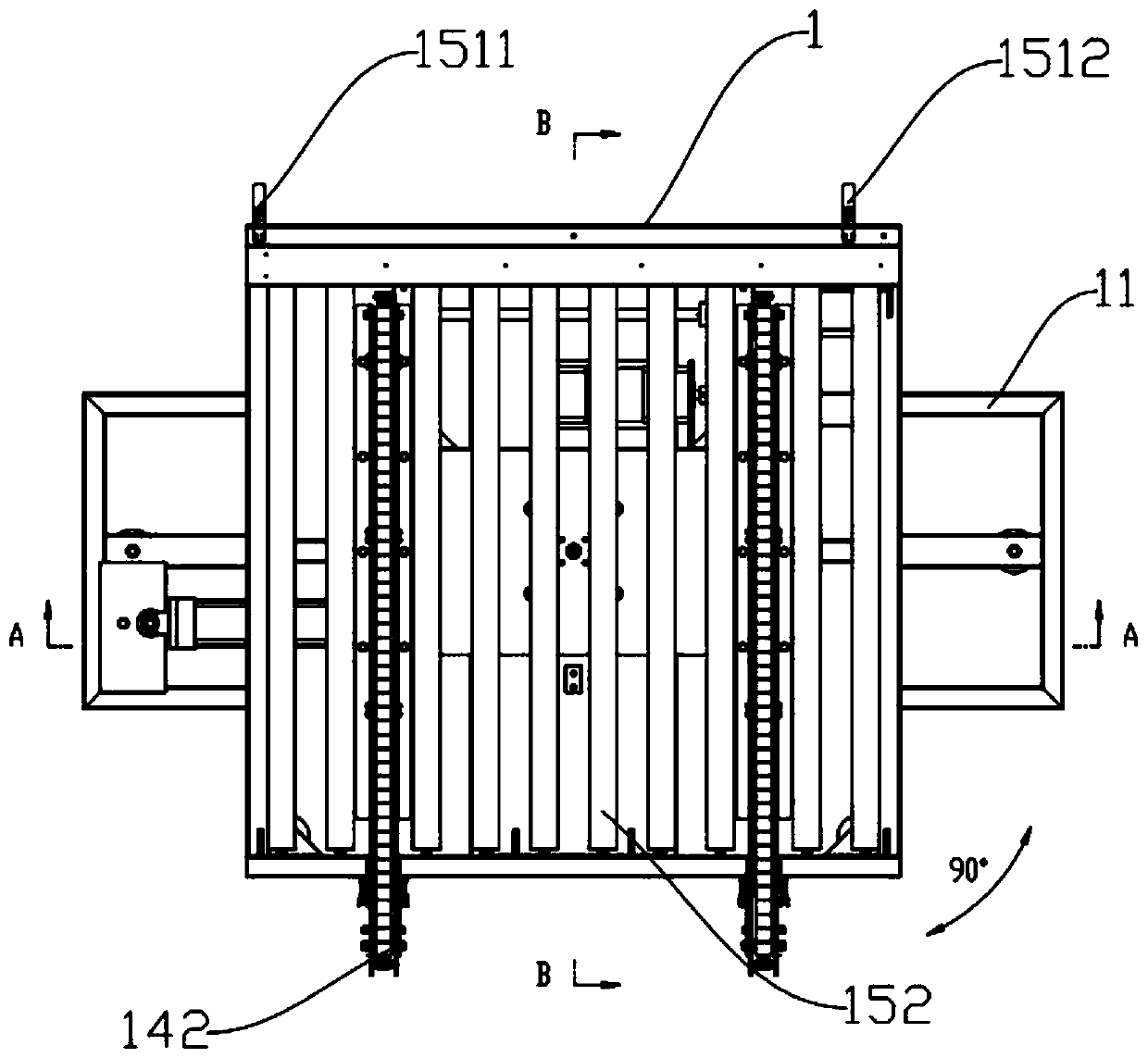

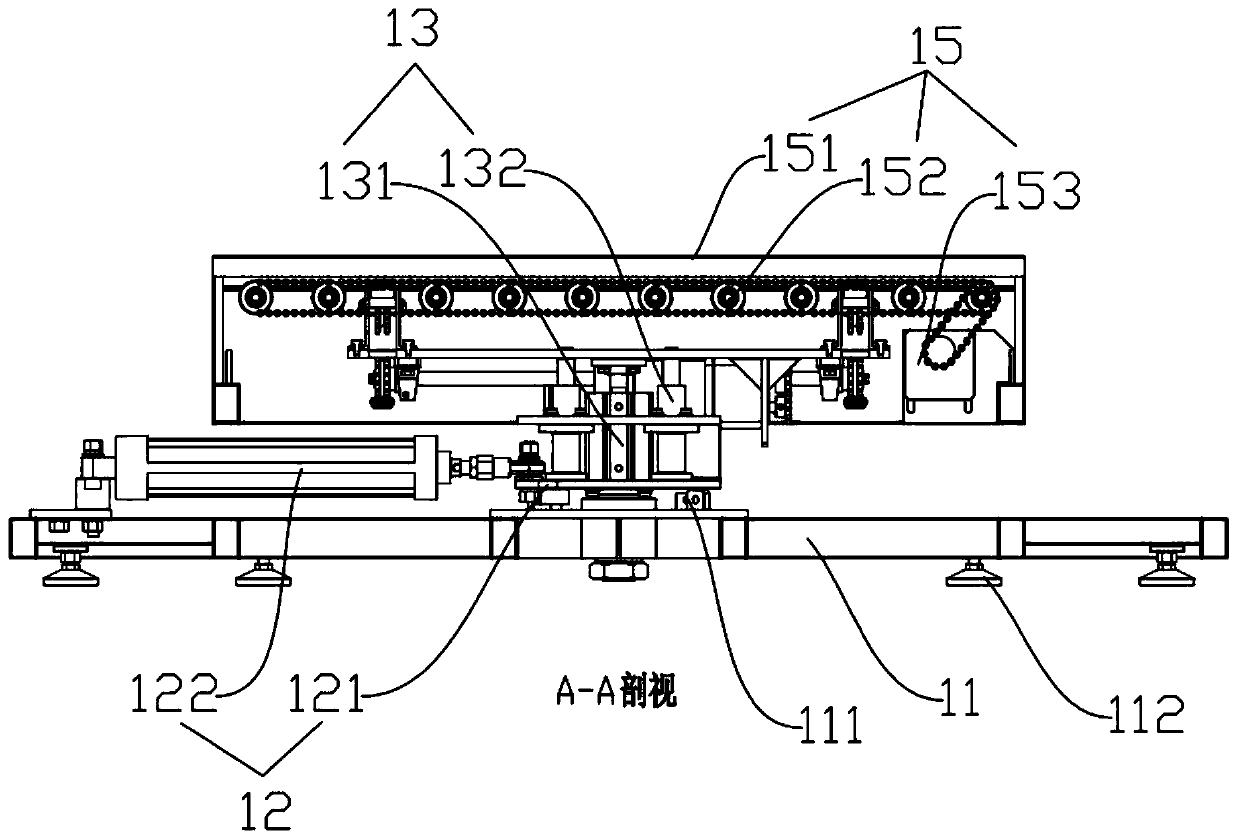

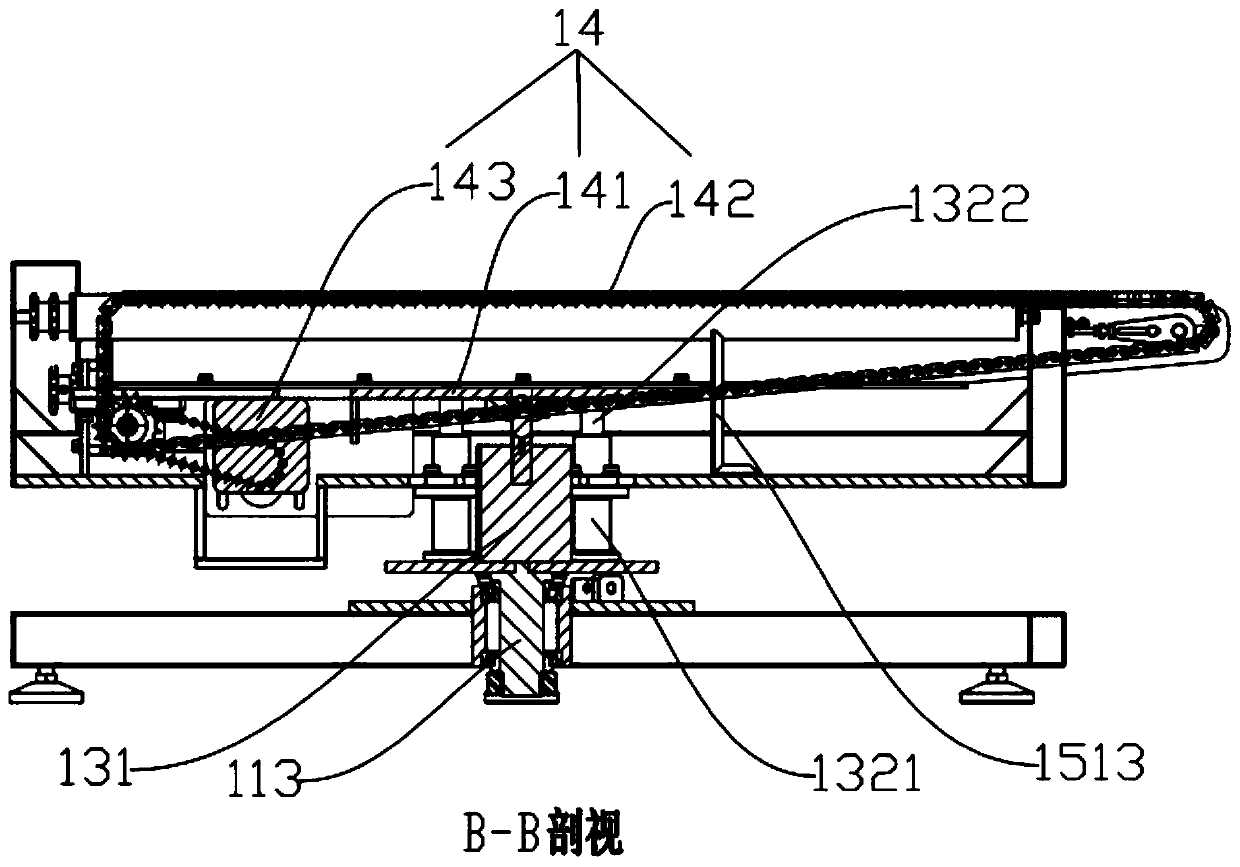

[0032] refer to Figure 1~3 , a steering lifting transfer platform, including an electrically connected transfer platform main body 1 and a controller (not shown in the figure), the transfer platform main body 1 includes an underframe 11 for supporting, the transfer The station main body 1 also includes:

[0033] The steering mechanism 12 includes a rotating disk 121 that is rotatably connected to the underframe 11, and a steering cylinder 122 that is rotatably connected to the rotating disk 121 at one end and rotatably connected to the underframe 11 at the other end; The bottom is fixedly connected with a connecting shaft 113 , and the rotating disk 121 rotates relative to the bottom frame 11 with the connecting shaft 113 as a rotation axis.

[0034] The lifting mechanism 13 includes a lifting cylinder 131 fixedly connected to the rotating disk 121, and a lifting guide mechanism 132 distributed around the lifting cylinder 131;

[0035] The transfer mechanism 14 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com