Clamping mechanism and clamping cutting platform

A clamping mechanism and clamping component technology, applied in the direction of clamps, workbenches, manufacturing tools, etc., can solve problems such as unstable clamping, and achieve the effect of solving unstable clamping and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

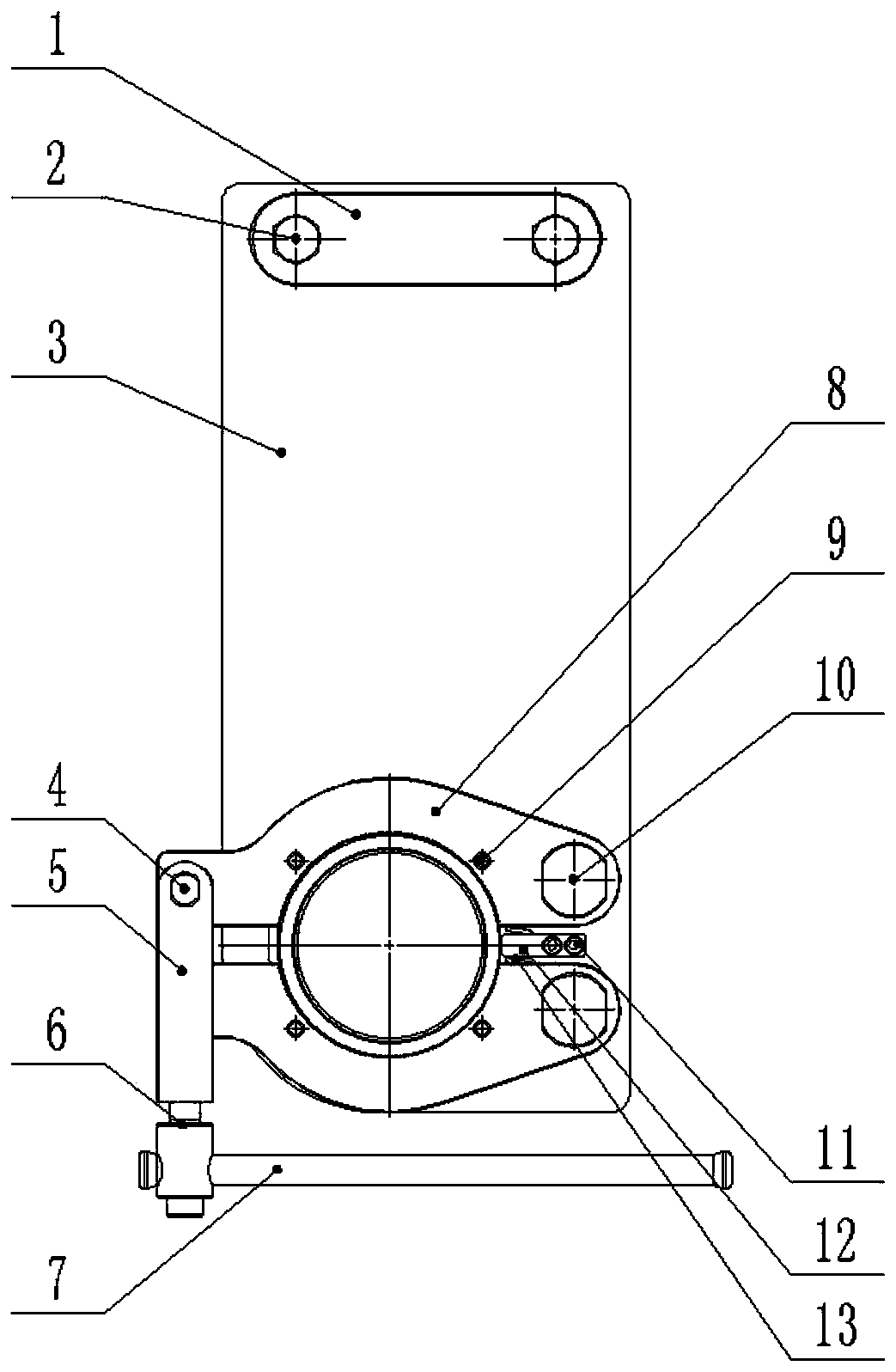

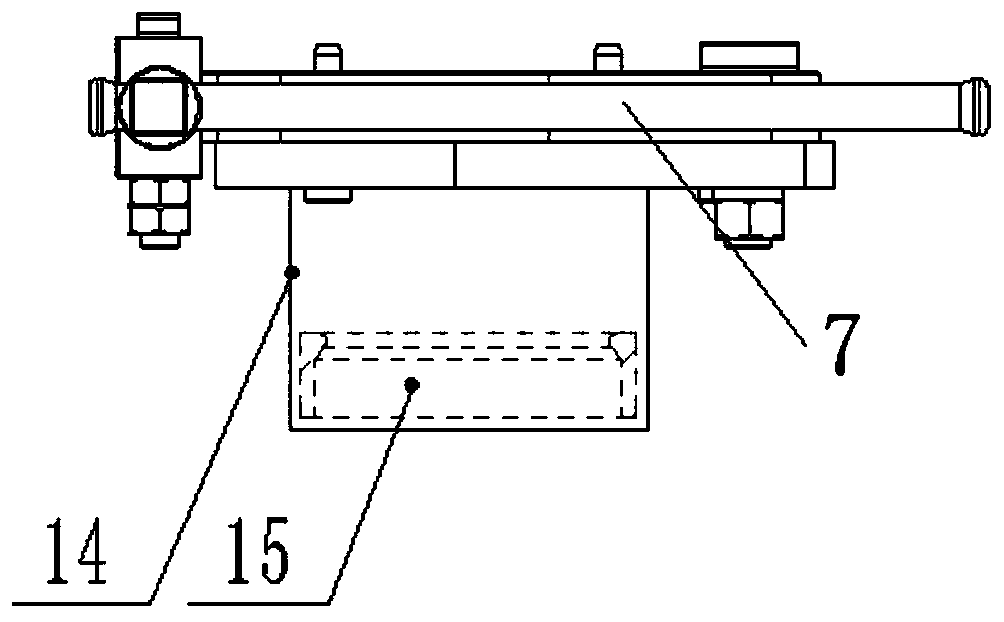

[0039] The first embodiment of the present invention provides a clamping mechanism, such as figure 1 As shown, the clamping mechanism includes a disassembly table 3, a locking assembly, a clamping assembly and a limit sleeve 14;

[0040] The clamping assembly is hinged on the disassembly table 3, and the limit sleeve 14 is fixed on the side opposite to the clamping assembly on the disassembly table 3, and penetrates through the clamping assembly;

[0041] The locking component is hinged to the clamping component;

[0042] Wherein, the locking assembly is tightened to open or lock the clamping assembly.

[0043] In this example, if figure 1 As shown, the clamping mechanism includes a table top pressure plate 1, a dismantling table top 3, a locking assembly, a clamping assembly and a limit sleeve 14. The table top pressure plate 1 is arranged on the disassembly table top 3, and both can be fixed by fixing bolts 2. The holding assembly is hinged on the disassembly table 3, and...

Embodiment 2

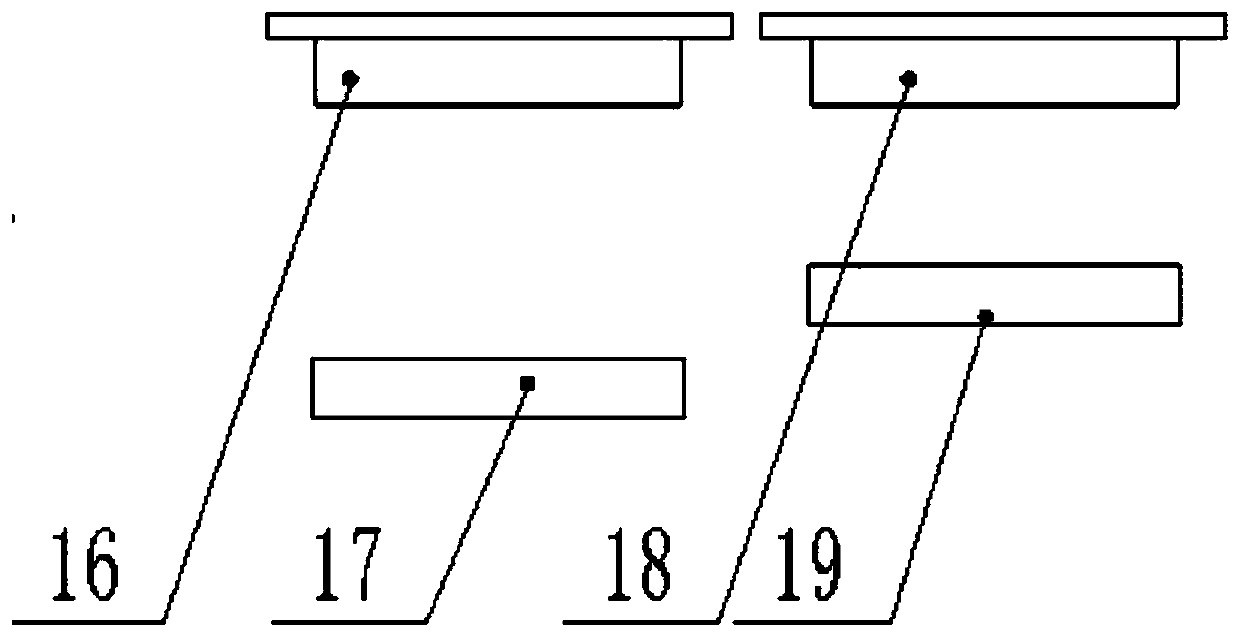

[0082] The second embodiment of the present invention provides a clamping and cutting platform, including the aforementioned clamping mechanism.

[0083] Specifically, this embodiment proposes a clamping and cutting platform for ammunition. The aforementioned clamping mechanism is provided on the clamping and cutting platform. Through the clamping and cutting platform, the ammunition can be further processed after the clamping mechanism completes the clamping of the ammunition. For example, for processes such as cutting, the stability and processing efficiency of the clamping platform can be further improved by providing the aforementioned clamping mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com