Convenient-to-move type fully-automatic grinding machine

A mobile and fully automatic technology, applied in the direction of grinding machines, grinding beds, grinding frames, etc., can solve the problems of improving work efficiency, inconvenience for operators, and inconvenient use, so as to improve work efficiency, reduce labor intensity, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

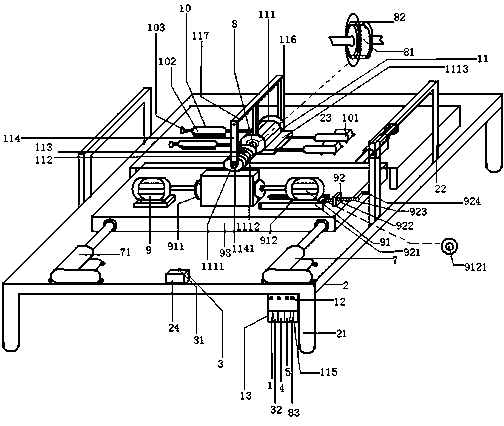

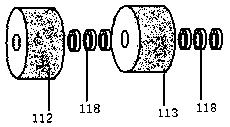

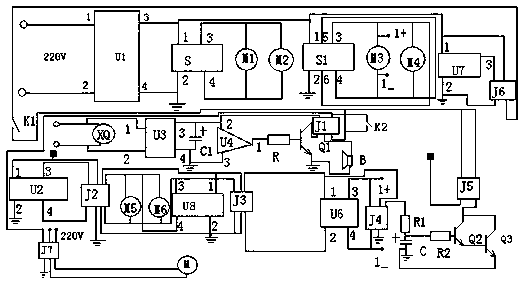

[0020] figure 1 , 2As shown in , a convenient mobile automatic grinding machine includes a switching power supply 1, a rectangular support plate 2 with four support feet 21 around the lower end and a "∩"-shaped handle 22 on the upper part of both sides, and a power switch 12. It also has a photoelectric control circuit 3, a first control circuit 4, a second control circuit 5, a longitudinal movement mechanism 7, a load protection mechanism 8, an overturn mechanism 9, a lateral movement mechanism 10, and a grinding wheel mechanism 11; A "∩" shaped rectangular rear support plate 23 is welded on the upper part of the side end, and the grinding wheel mechanism 11 includes an AC motor 111 and two different coarse grinding wheels 112 and fine grinding wheels 113 (the outer diameter of the coarse grinding wheel 112 is smaller than the outer diameter of the fine grinding wheel 113). , in actual processing, the parts are first ground by the coarse grinding wheel 112, and the outer dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com