Clamping fixture for outer cylinder parts

A technology for parts and outer cylinders, applied in the field of clamping fixtures for outer cylinder parts, can solve the problems of radial rotation and axial movement, achieve reliable positioning and clamping, avoid axial rotation and movement, and simplify the process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

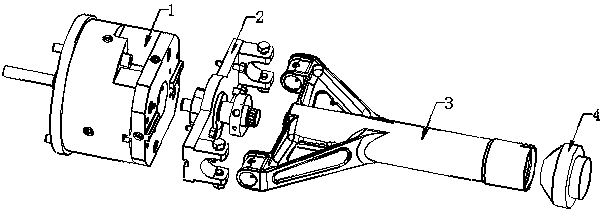

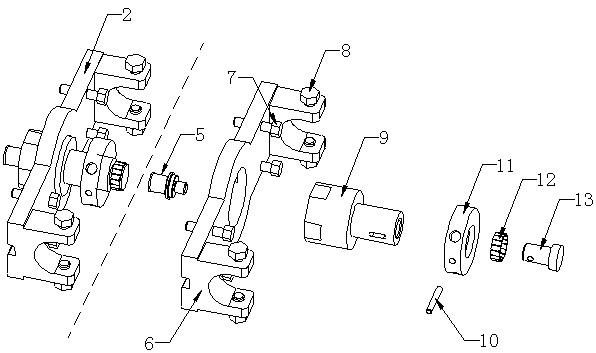

[0037] A clamping fixture for outer cylinder parts, aimed at realizing the clamping of outer cylinder parts 3 on a rotary machine tool, such as figure 1 As shown, it includes a flexible clamping system 1, a transfer fixture 2, a part to be processed 3, and a tip 4. Such as figure 2 As shown, the transfer fixture 2 includes a zero-point positioning pull stud 5 , a base plate 6 , a bolt 7 , a base shaft 9 , a positioning pin 10 , a tension ring 11 , a slotted bush 12 , and a tapered pin 13 .

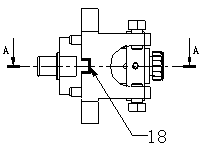

[0038] Such as Figure 5 As shown, the left end of the base shaft 9 has a threaded hole for installing the zero point positioning pull stud 5, the right end has a high-precision inner hole 14, and the outer circle of the right end has an external thread 15; the tension ring 11 is provided with an internal threaded hole 16, and the internal threaded hole 16 cooperates with external thread 15; as image 3 , Figure 4 As shown, there is a high-precision keyway 18 on the base plate 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com