Angle iron assembly device

A technology for assembling devices and angle irons, applied in auxiliary devices, auxiliary welding equipment, welding/welding/cutting items, etc., can solve the problems of high requirements for mechanical automation, positioning accuracy affecting the quality of finished products, and increasing the difficulty of research and development. Save manpower, meet the needs of automated production, improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

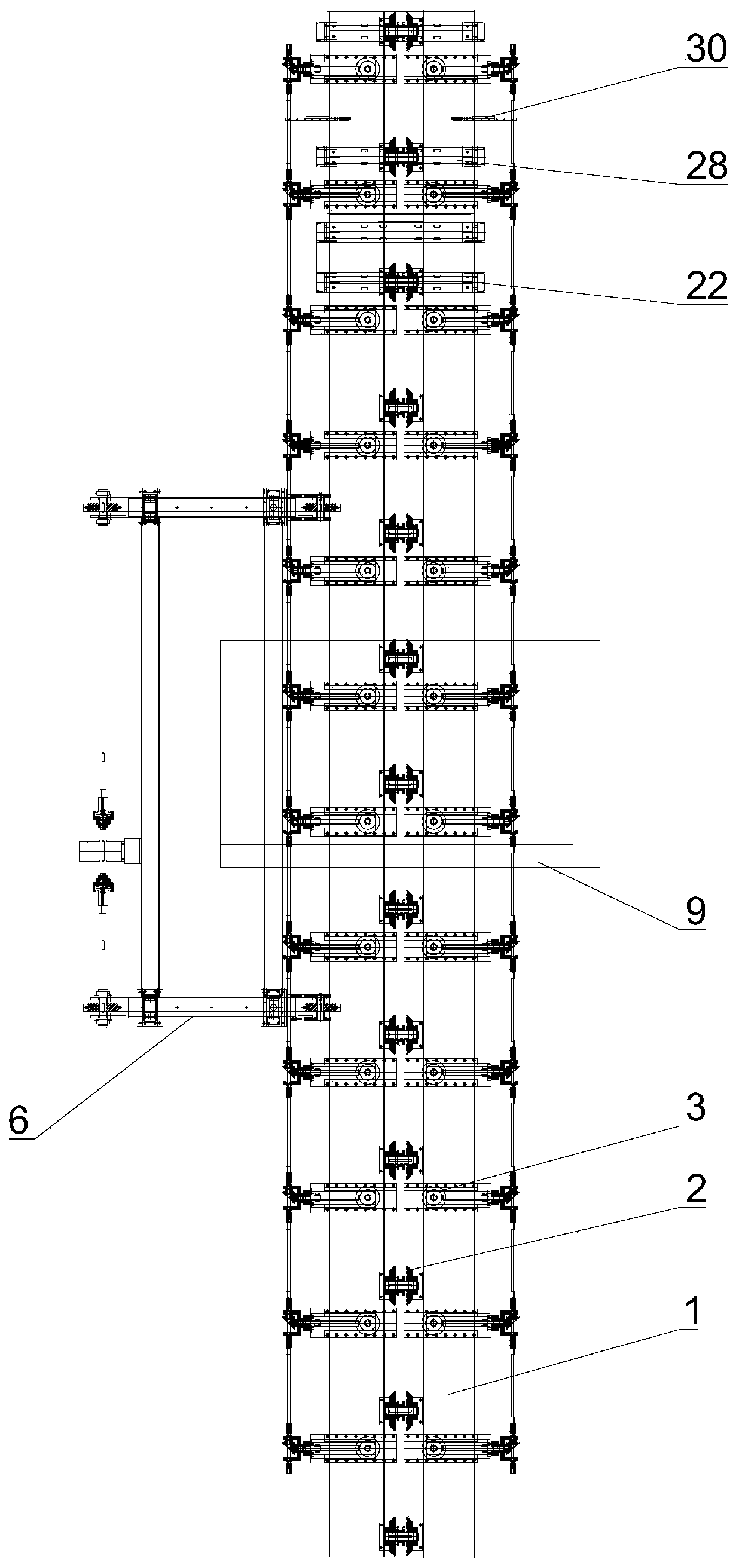

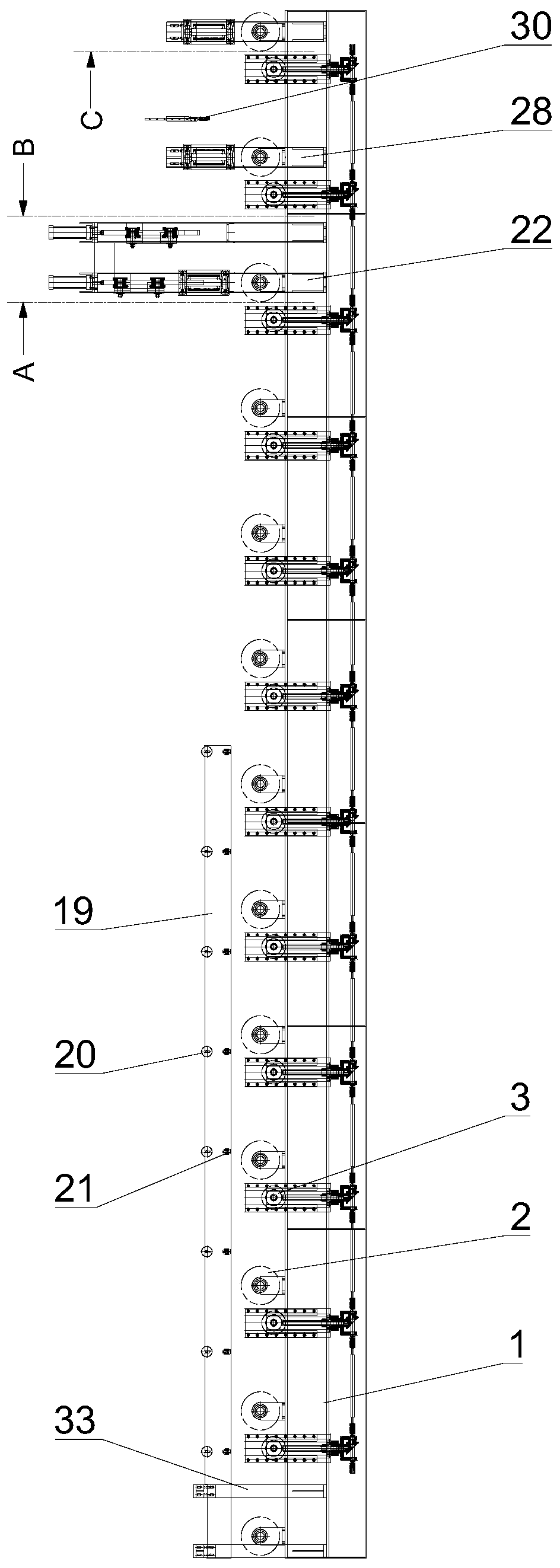

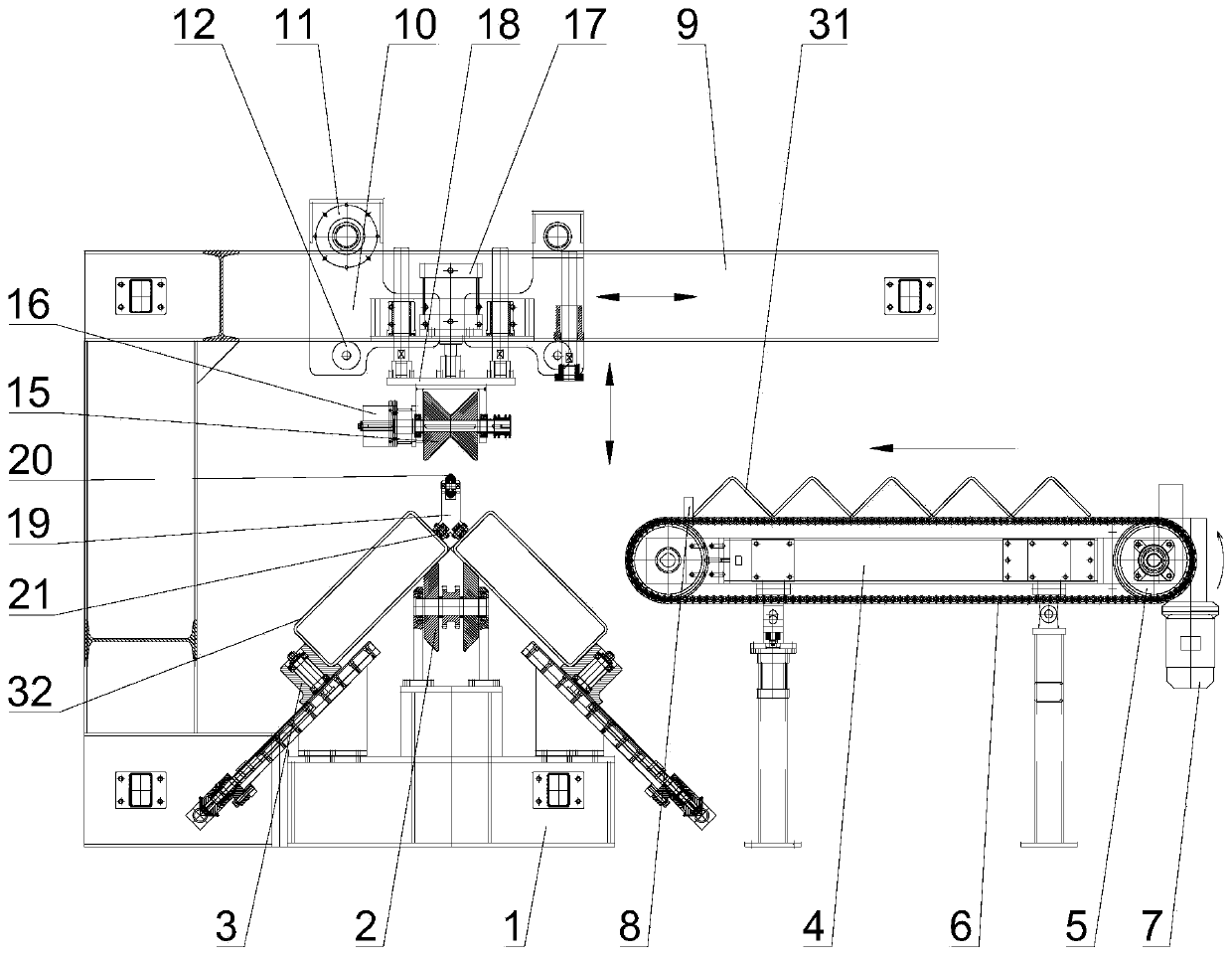

[0028] see Figures 1 to 7 As shown, this embodiment provides an angle iron assembling device for assembling two "L"-shaped spliced square tubes 32 and angle irons 31, which includes a support seat 1, a feeding mechanism, a limit mechanism and a welding mechanism.

[0029] Due to the specific splicing shape, the two square tubes 32 need to be fixed first, and then combined with the angle iron 31 . Therefore, the supporting base 1 is provided with conveying rollers 2 and guide assemblies located on both sides of the conveying rollers 2. Several conveying rollers 2 are arranged at intervals along the length direction of the supporting base 1 to form a production conveying line. The guiding assemblies include guide wheels 3 , the conveying roller 2 comprises two tapered surface wheels inclined to both sides, the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com