Bridge dynamic load automatic detection and inversion system and method

An automatic detection and dynamic load technology, which is applied in measurement devices, image data processing, 3D image processing, etc., can solve the problems of no heavy-duty and empty-vehicle distinction function, and inability to achieve multiple video synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

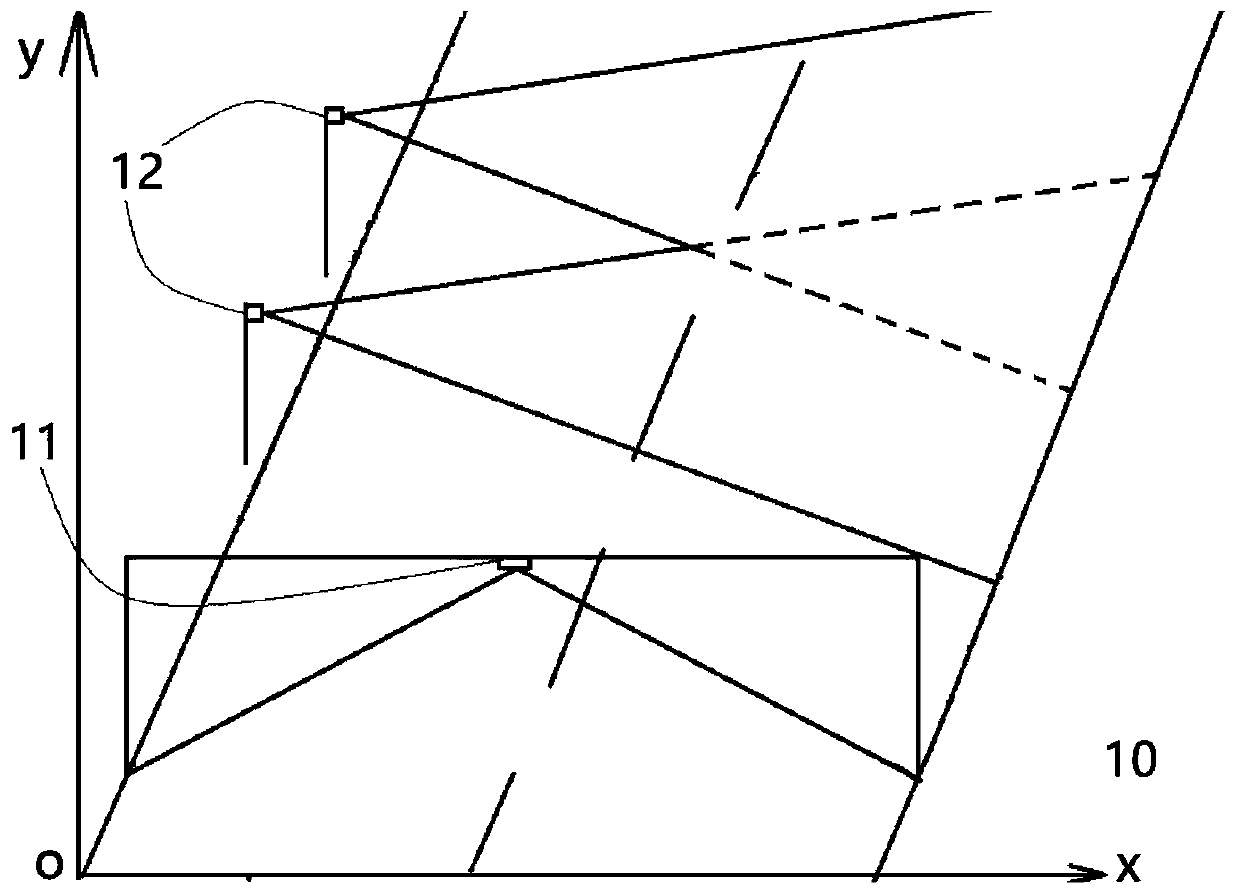

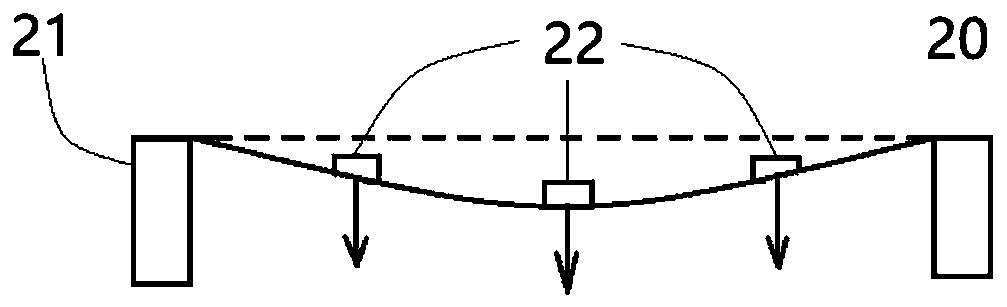

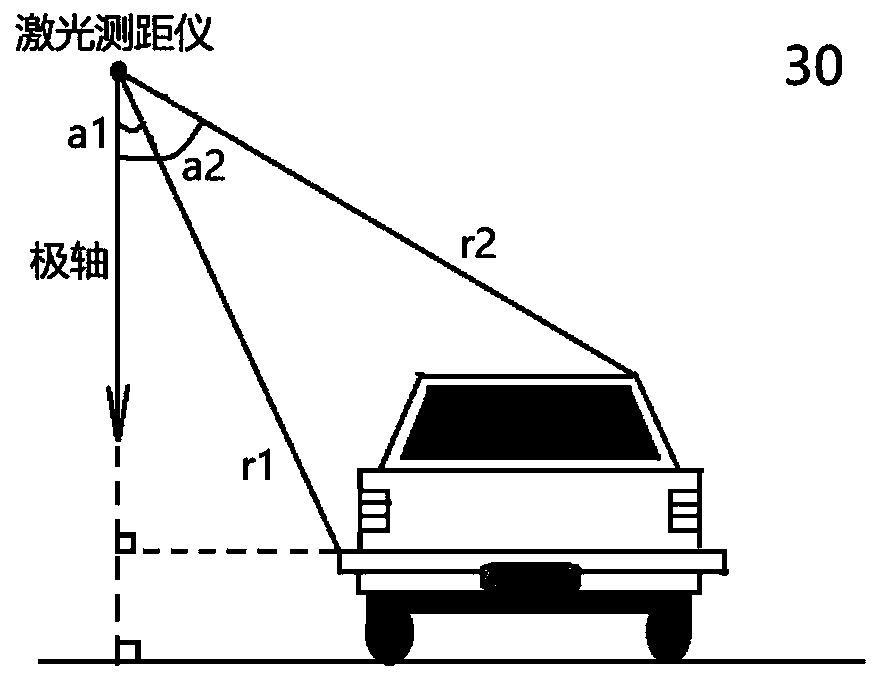

[0087] see Figure 1 to Figure 8, a bridge dynamic load automatic detection and inversion system, including a three-dimensional laser scanner 11, a computer, a plurality of cameras 12 and a timer for cooperating with the three-dimensional laser scanner 11; There are multiple road poles, and each road pole is equipped with a camera 12 that covers the field of view of the lane area between two adjacent road poles. Multiple cameras take pictures synchronously, and the synchronization accuracy is less than 10 microseconds. Three-dimensional laser The scanner 11 is erected directly above the double lanes in the same direction at the entrance of the bridge and the measurement range covers two lanes; the bridge 21 is at least provided with a stress sensor at the maximum force of the bridge, a stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com