Deformable assembly for downhole tool and downhole tool

A technology of downhole tools and deformable parts, which is applied in wellbore/well parts, earthwork drilling, sealing/isolation, etc. It can solve the problems of limited annular space and large sealing mechanism, and achieve the effect of increasing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0065] For the sectional view of embodiment three, see Figure 6 , compared with Embodiment 1, the difference lies in that the inner surface of the deformable part of the deformable assembly main body 1 has a tapered structure. The inner surface has a tapered structure, which is convenient for adapting to the tapered shaft core, and the entire downhole tool is relatively short.

Embodiment 4

[0066] For the cross-sectional view of embodiment four, see Figure 7 , compared with the second embodiment, the difference lies in that the inner surface of the deformable part of the deformable assembly main body 1 has a tapered structure. The inner surface has a tapered structure, which is convenient for adapting to the tapered shaft core, and the entire downhole tool is relatively short.

Embodiment 5

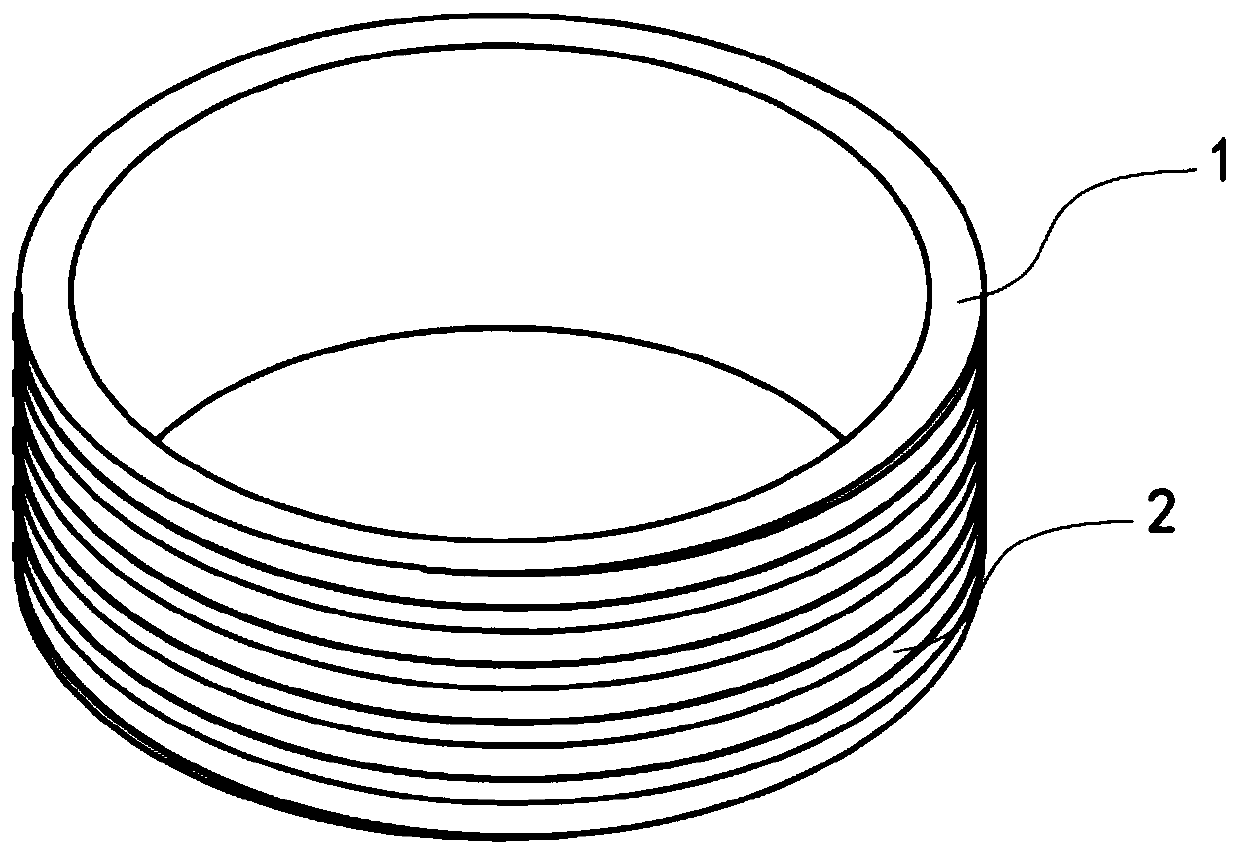

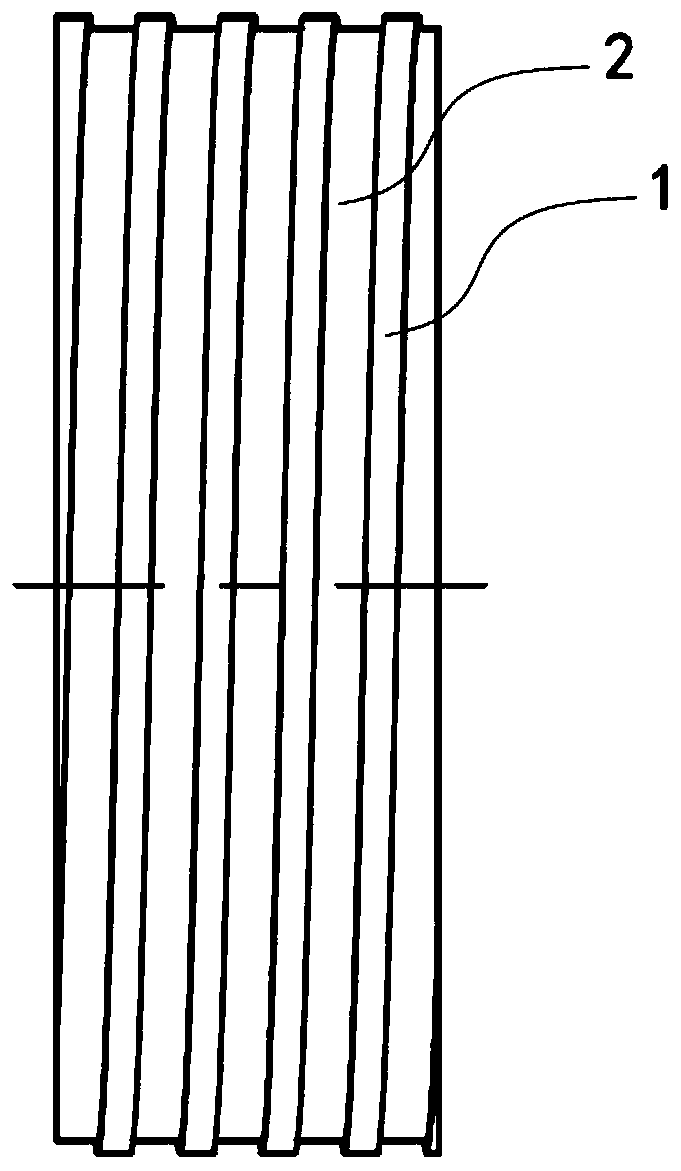

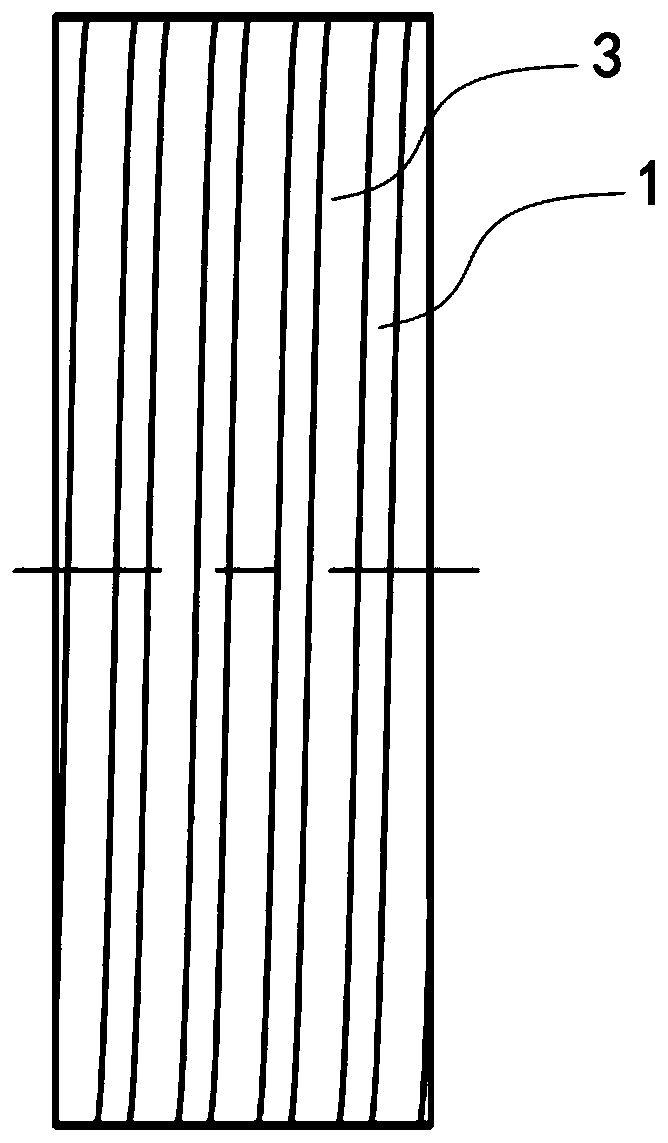

[0067] For the structural diagram of Embodiment 5, see Figure 8 , Figure 9 and Figure 10 , compared with the third embodiment, the difference is that the depth direction of the spiral groove structure 2 runs through the entire deformable component body 1; the spiral groove structure 2 is filled with sealing material 3 .

[0068] Since the depth direction of the spiral groove structure 2 runs through the entire deformable component body 1, the deformable component is in the shape of a spring as a whole. When the sealing material 3 is arranged in the spiral groove structure, the sealing material 3 can be on the outside of the deformable component body 1 and The inner side of the main body of the deformable component forms a sealing structure to ensure the sealing effect.

[0069] For the structure and working state diagram of the first embodiment of the downhole tool, please refer to Figure 11 and Figure 12 . Including the mandrel 5, the deformable assembly is the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com