Method for preparing PE water supply pipe

A technology for water supply pipes and formulations, applied in the direction of tubular items, applications, household appliances, etc., can solve the problems of breeding bacteria, reducing the strength of pipes, irregularities on the surface of pipes, etc., to achieve precise control, improve processing performance, improve strength and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0026] A preparation method of PE water supply pipe, the material formula of PE water supply pipe includes: polyethylene resin (PE), polyethylene wax (PE wax), nano carbon black, metallocene catalyst, antioxidant and nano silver antibacterial agent, wherein poly The mass proportion of ethylene resin (PE) is 45%, the mass proportion of polyethylene wax (PE wax) is 25%, the mass proportion of nano carbon black is 20%, the mass proportion of metallocene catalyst is 6%, The mass proportion of antioxidant is 3%, and the mass proportion of nano-silver antibacterial agent is 1%;

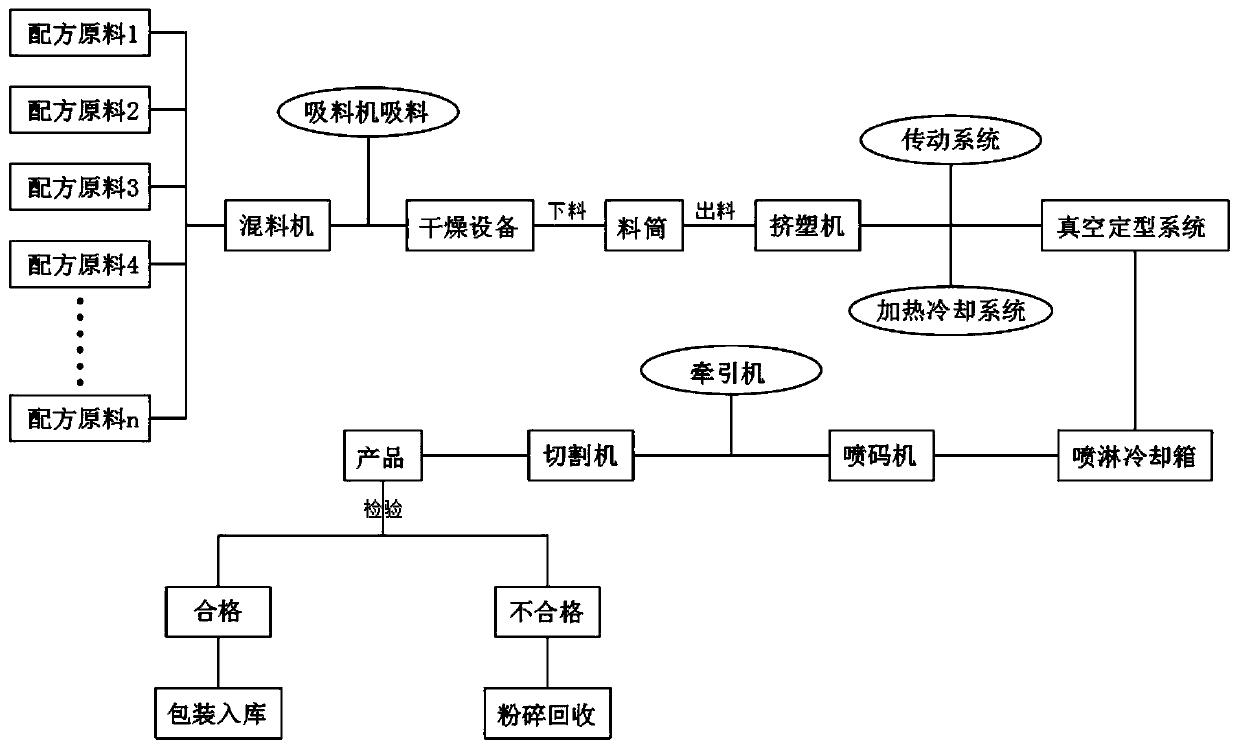

[0027] like figure 1 Shown, the preparation method of PE water supply pipe mainly comprises the following steps:

[0028] S1. Mixing; add the formula material of the PE water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com