Clamping tool for PCB processing

A PCB board and clamping tooling technology, which is applied in clamping devices, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting processing accuracy and processing errors, and achieve the effect of avoiding displacement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

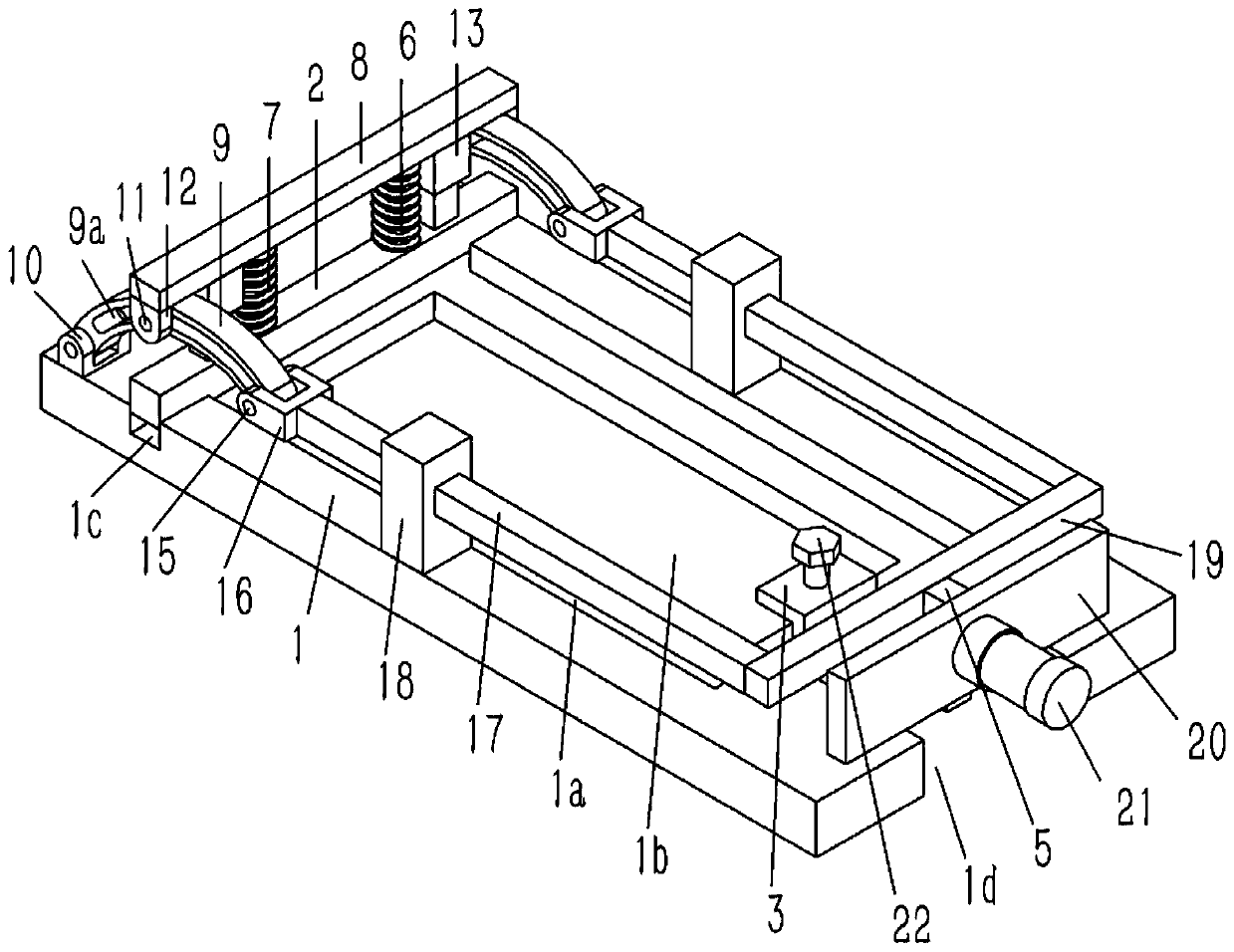

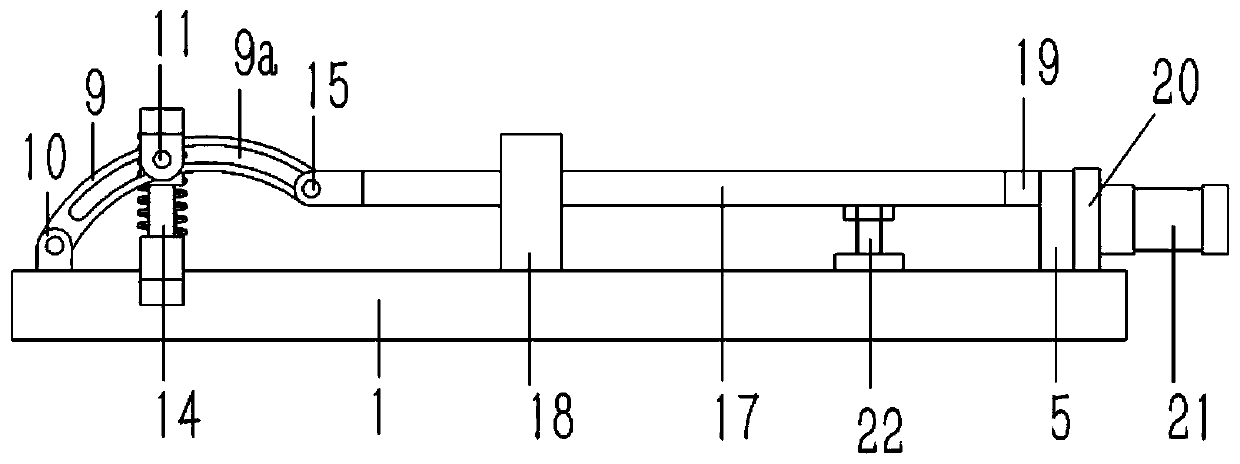

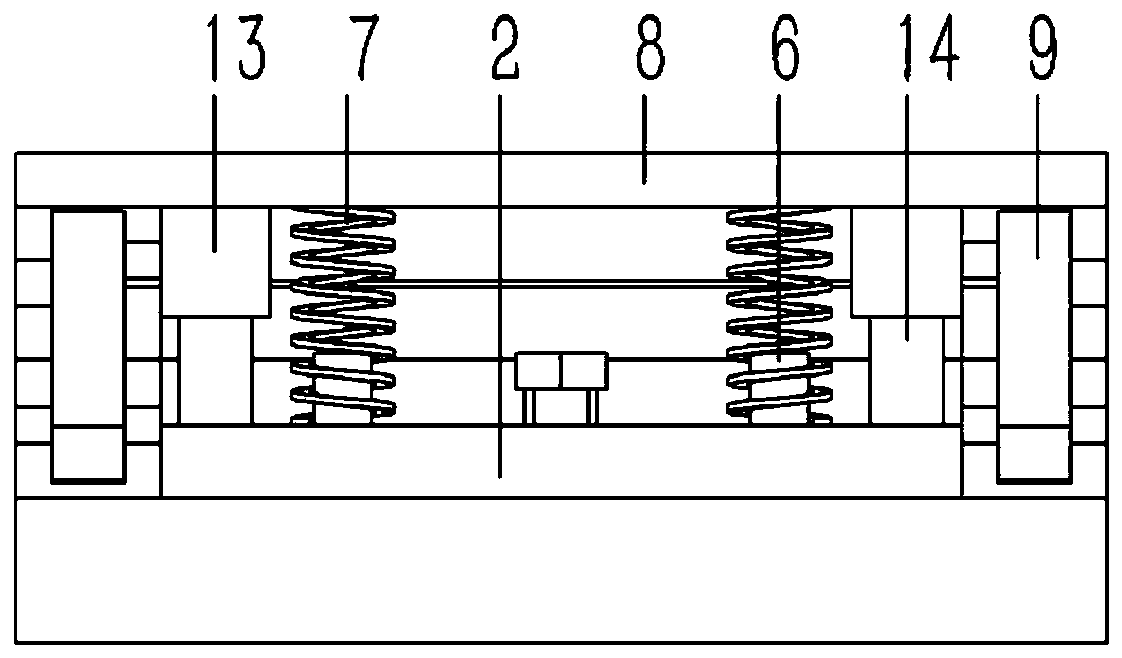

[0020] Example: see Figures 1 to 4 As shown, a clamping tool for PCB board processing includes a clamping platform 1. A rectangular concave platform 1a is formed on the upper end surface of the clamping platform 1. The upper end surface of the clamping platform 1 on the left side is formed with a longitudinal groove 1c communicating with the concave table 1a, and the middle part of the right side of the clamping platform 1 is formed with a rectangular notch 1d. A longitudinal bead 2 is inserted into the longitudinal groove 1c, and an L-shaped push block 3 is inserted on the right side of the concave table 1a of the clamping platform 1, and a push rod 4 is fixed on the right end surface of the push block 3, and the push rod 4 is inserted into the Connected to the right side wall of the concave table 1a, the right end of the push rod 4 is inserted into the notch 1d of the clamping platform 1;

[0021] A number of connecting columns 6 are fixed on the upper end surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com