Clamp for vacuum brazing

A fixture and brazing technology, applied in the field of vacuum brazing fixtures, can solve problems such as large welding defects, relative position deviation of brazing parts, etc., and achieve the effect of solving the problem of equality matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

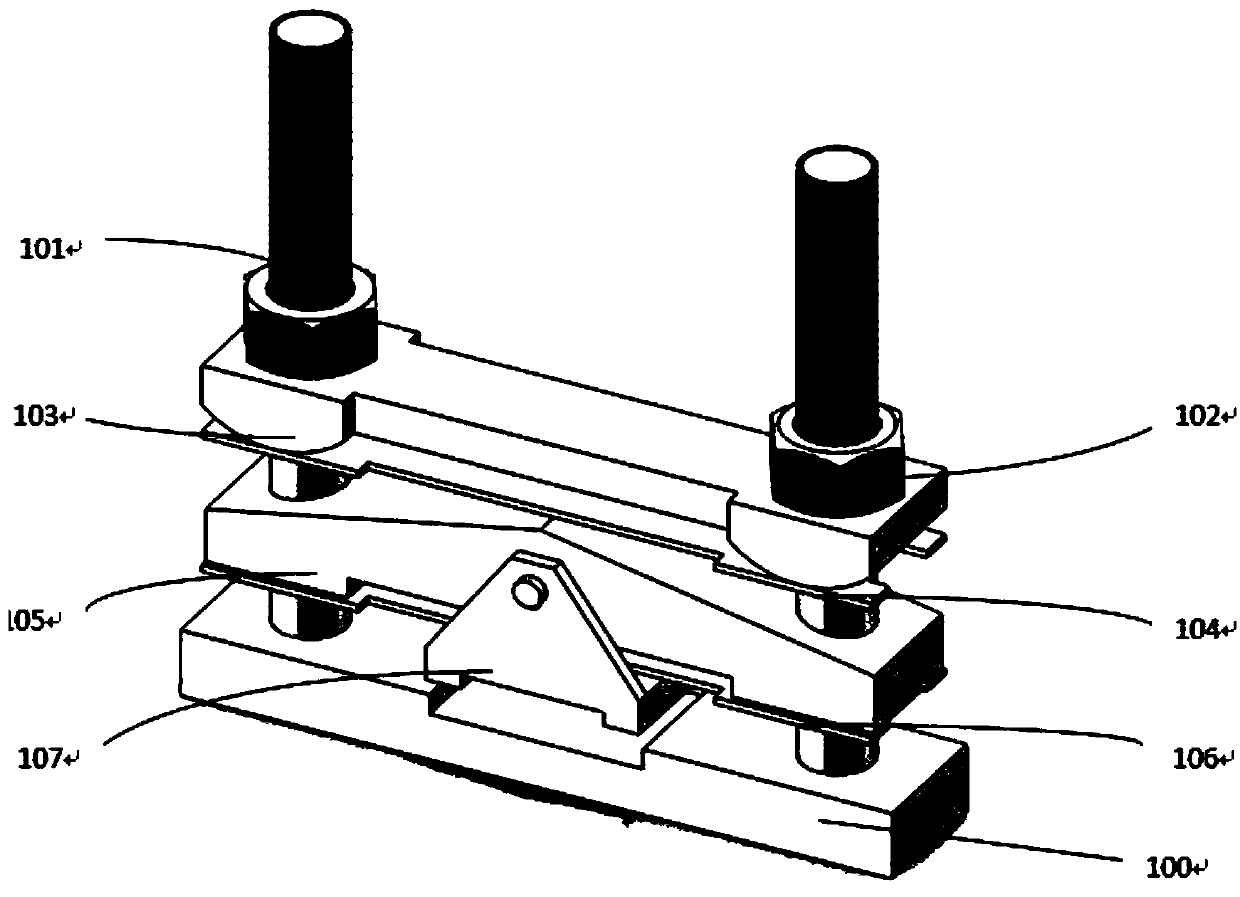

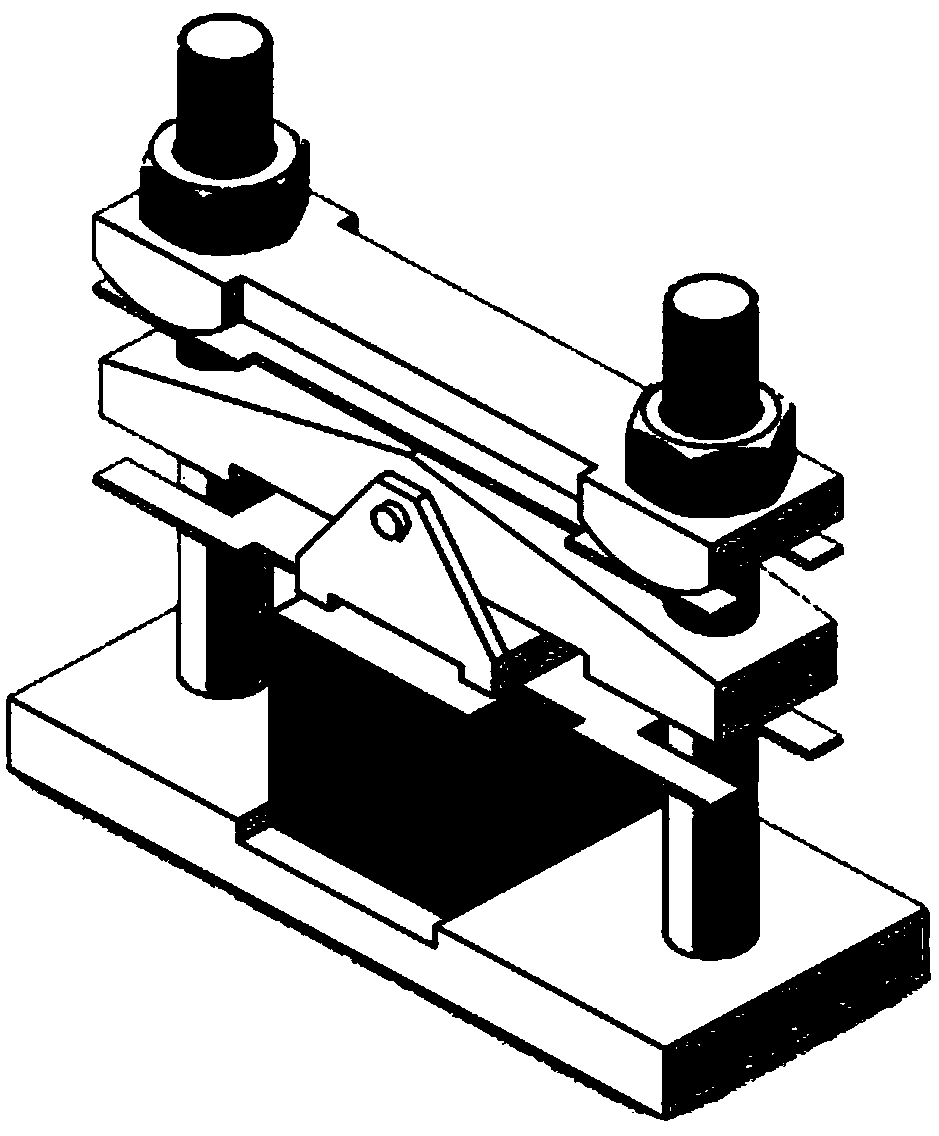

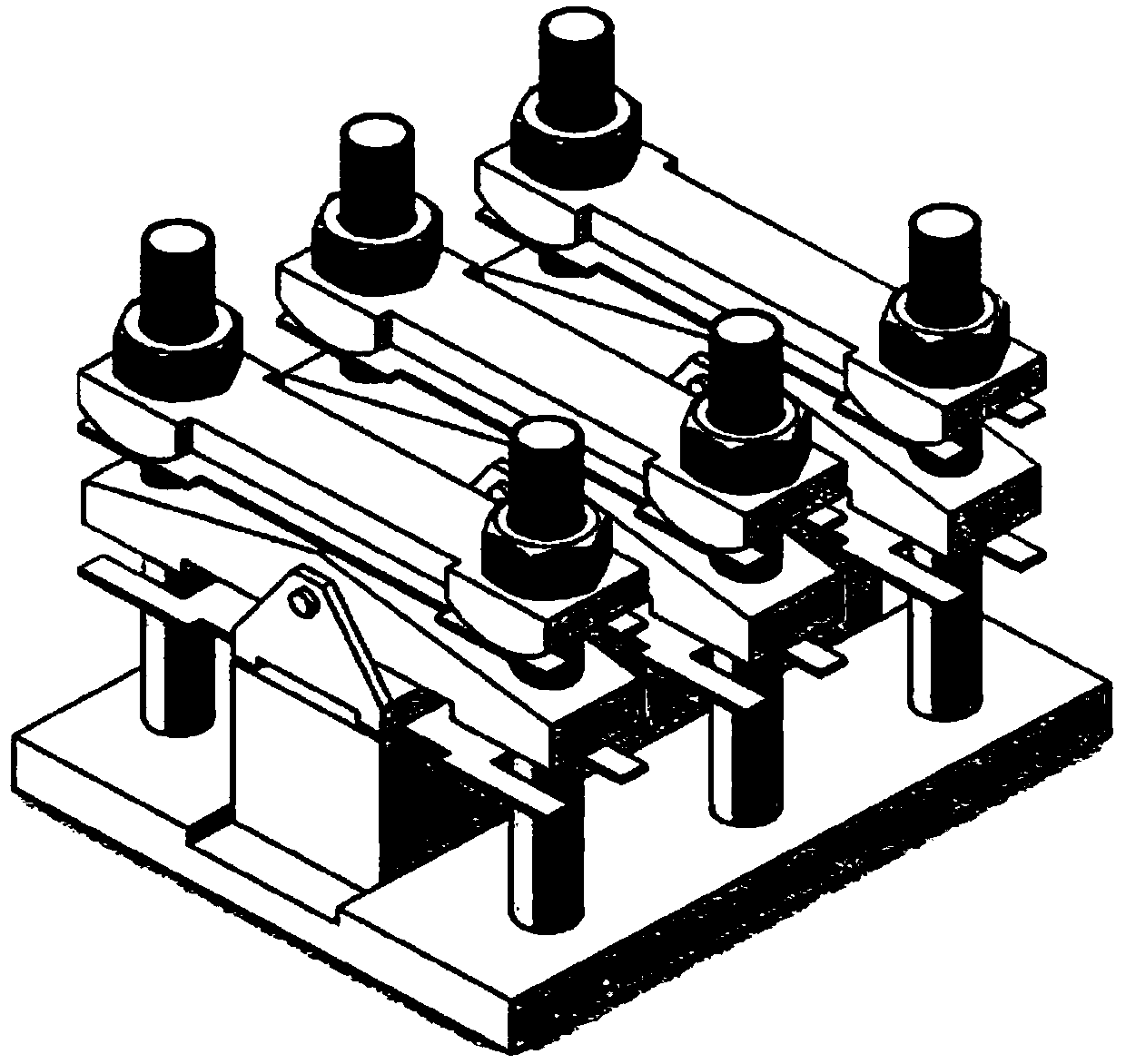

[0029] A vacuum brazing fixture for connecting and positioning the surface wall unit of the divertor and the heat sink material, comprising: a bottom plate 100, bolts, an upper fixing block 103, a lower fixing block 105, an elastic piece 104 and a positioning block 107.

[0030] The clamp bottom plate 100 includes a base plate, a limiting groove and a plurality of bolt holes arranged on one surface of the base plate, and the number of bolt holes is determined according to the size of the divertor.

[0031] The bolt includes a bolt column 101 and a nut 102. Both ends of the bolt column 101 have threads. The thread lengths at both ends are one long and one short. The short threaded end is used to connect with the base plate 100, and the long threaded end is used in conjunction with the nut 102 to directly align. The fixed block 103 applies pressure.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com