Dynamic locking workpiece punching device

A workpiece, dynamic technology, applied in positioning devices, feeding devices, metal processing machinery parts, etc., to achieve the effect of improving drilling efficiency and stability, and improving drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

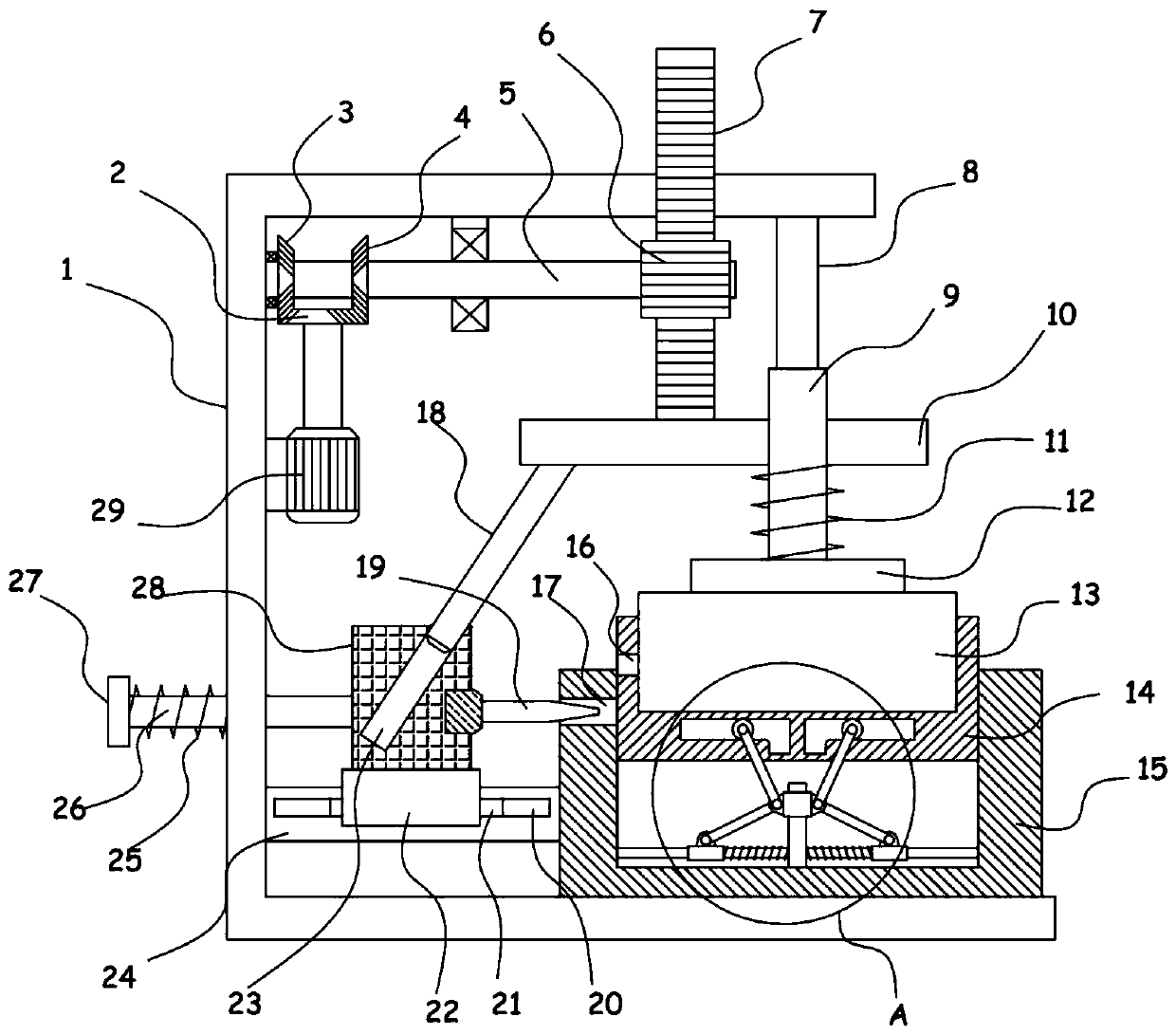

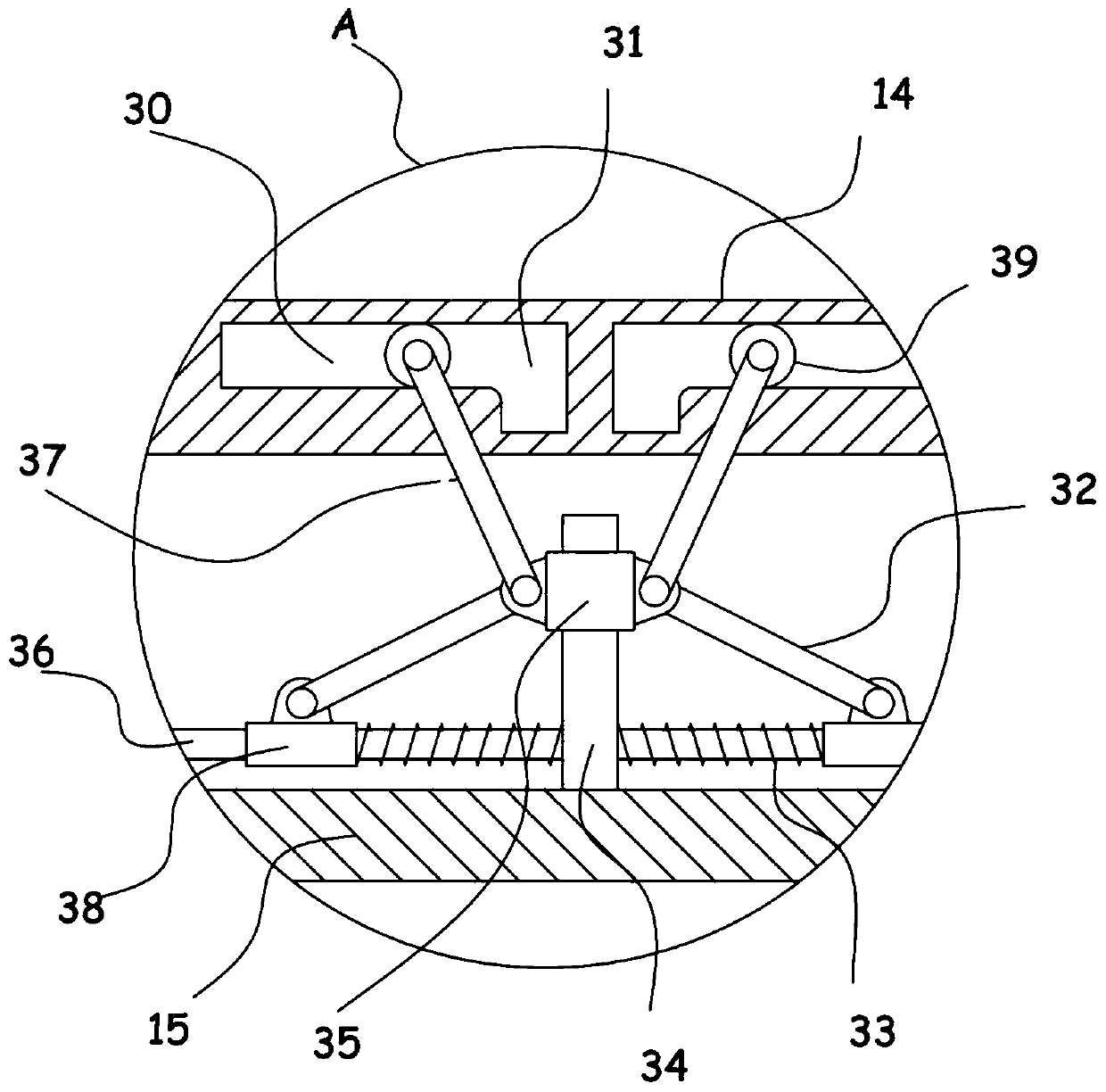

[0022] See Figure 1-2 , A device for dynamically locking a workpiece hole, comprising a support frame 1, a limit slot 15 is fixed on the support frame 1, a fixing frame 24 is fixed on the side wall of the limit slot 15, and the limit slot 15 is connected by an elastic support mechanism There is a vertically slidable bracket 14 for carrying the workpiece 13. A servo motor 29 is fixed on the support frame 1, and a transmission shaft 5 is connected to the servo motor 29 through a steering mechanism, and a lifting mechanism is connected to the transmission shaft 5, The bottom of the lifting mechanism is provided with a pressing mechanism corresponding to the workpiece 13 vertically, and a transmission block 28 is slidably mounted on the fixed frame 24. The transmission block 28 is connected to the pressing mechanism by a transmission mechanism. The side wall of the transmission block 28 A drill bit 19 is provided. The side wall of the limiting slot 15 is provided with a sliding ca...

Embodiment 2

[0028] On the basis of embodiment 1, in addition, the lifting mechanism of the device includes a rotating transmission shaft 5, a transmission gear 6 is sleeved and fixed on the transmission shaft 5, and the transmission gear 6 is meshed and connected with a straight line whose lower end is fixed to the horizontal plate 10. The rack 7 drives the transmission gear 6 to rotate during the rotation of the transmission shaft 5, and the transmission gear 6 drives the straight rack 7 to move vertically downwards. At this time, the straight rack 7 drives the horizontal plate 10 to move down to realize the direction of the pressing plate 12 Move down and compress the workpiece 13.

[0029] The transmission mechanism of the device includes a chute 23 slantingly opened in the transmission block 28, the chute 23 is slidably embedded and installed with a chute 23 fixed at the bottom of the horizontal plate 10, and the side wall of the transmission block 28 is fixed with a sliding through suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com