Bi-component adhesive preparation device with magnetic stirring and overturning adhesive discharging functions

A magnetic stirring and agitator technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of wasting rubber material, affecting the use of glue, and high cost, and achieves extended service life, good mixing effect, and smooth glue path. broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

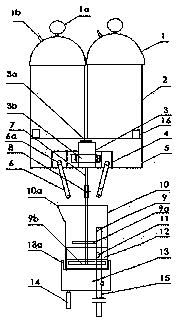

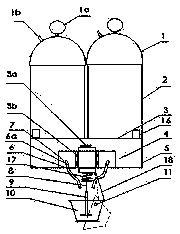

[0067] Such as figure 1 As shown, the storage barrels 2 containing components A and B respectively have an air pressure gauge 1a on the lid 1 and a pipe 1b connected to the air storage tank of the air compressor to maintain a constant pressure so that the glue flow and glue output are stable. The discharge pipes on the two storage tanks 2 are respectively connected to the inlet ends of the double-pipe feed valve 4, and the outlet ports 6a of the double-pipe feed valve 4 pass through the plate surface 5 supported by the support frame 16 and respectively connect with the two The conduit 6 is plugged in. A micro-motor 3 is arranged between the two conduits 6, and it is fixed on the plate surface 5 by the iron sheet 3a and the holding iron 3b. The rotating shaft 7 at the lower end of the motor 3 is connected with the stirring rod 9 through an adjustable coupling 8, The lower end of the stirring rod has a hinge 9a with a smaller rotation radius at a higher position, and a hinge 9b...

Embodiment 2

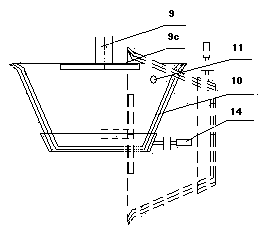

[0069] Such as figure 2 As shown, the two-component rubber material flowed quantitatively from the self-pressurized AB storage tank according to a certain ratio flows through the respective pipelines through the double-pipe feed valve fixed on a lower operating platform, and the double-pipe feed The outlet end of the valve is sleeved with a conduit, and the distance between the two outlets of the conduit is such that it can completely flow into the wide-mouth rubber nozzle. A motor is fixed directly above the wide-mouth rubber nozzle 10 by a support frame. There is a rotating shaft with a tapered lower end below it, and a hollow plastic stirring rod 9 is inserted on the rotating shaft with an interference at the upper end. The wide-mouth rubber nozzle 10 whose mouth diameter is larger than the height has a 25-45 degree inclination on the side wall can also use its taper to nest several same wide-mouth rubber nozzles in order to replace the innermost layer when necessary. A s...

Embodiment 3

[0071] The wide-mouth rubber nozzle 10 in the present invention can also be connected with the rotating shaft 11 or other overturning mechanisms through the extension structure, so that the wide-mouth rubber nozzle 10 can be installed and disassembled more easily; the shaft pin 11 can also be fixed directly or indirectly with the wide-mouth rubber nozzle Thereby rely on the rotation of control shaft 11 to realize overturning; slide block 13 can also be detachably fixedly connected with wide-mouth rubber nozzle 10, and the control part 14 of slide block 13 links to each other with overturning mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com