Air draft heat dissipation type electric power cabinet

A heat-dissipating, power cabinet technology, applied in the direction of electrical components, substation/power distribution device shell, substation/switch layout details, etc., can solve problems such as difficulty in heat dissipation, poor air flow, etc., to reduce service life, increase gas flow rate, The effect of reducing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

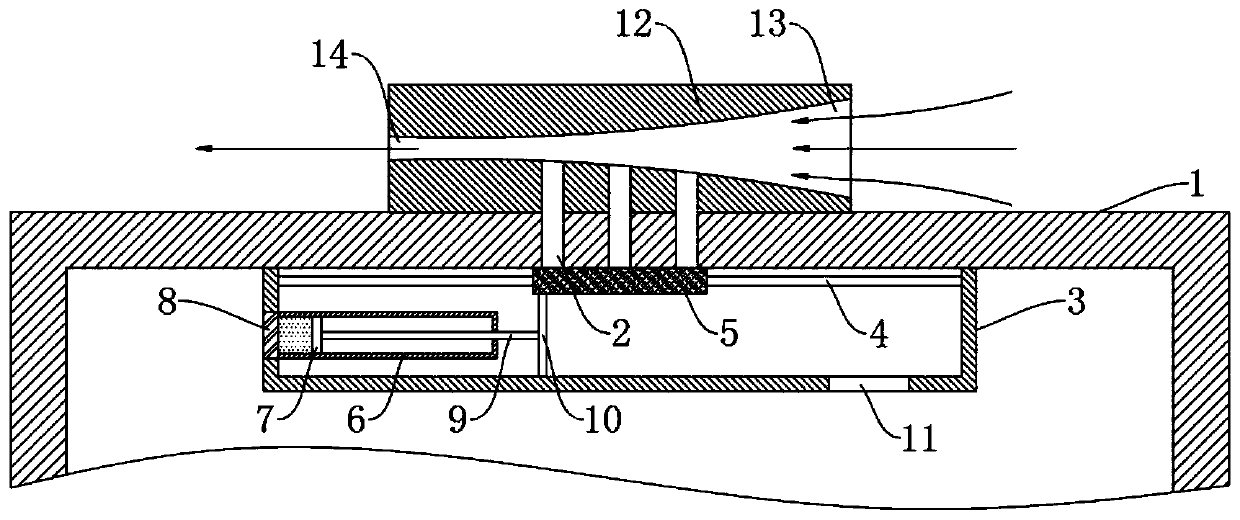

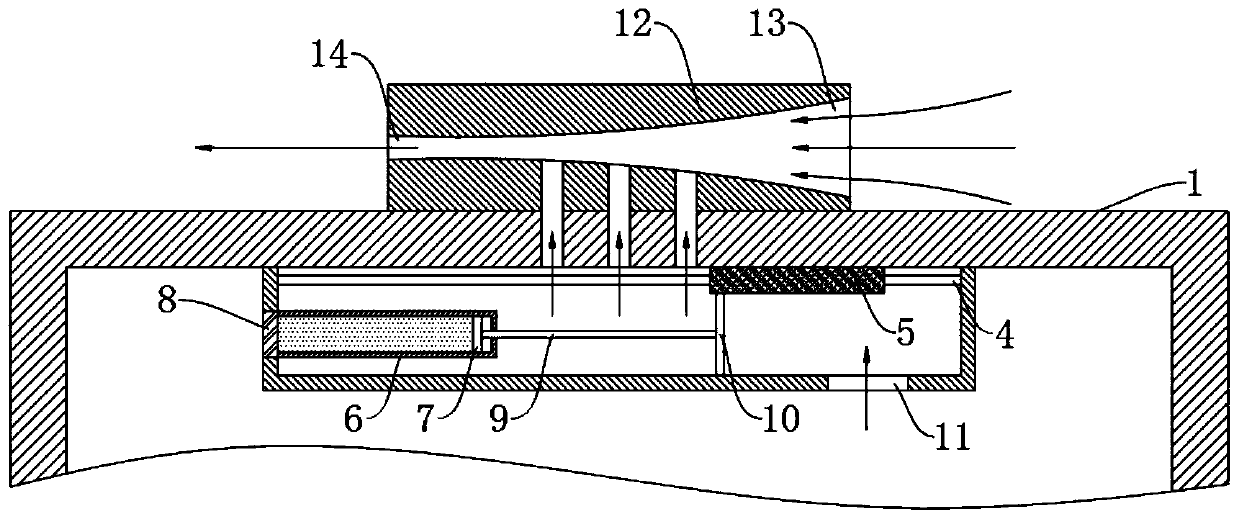

[0020] refer to Figure 1-2 , a kind of ventilation and heat dissipation power cabinet, comprising a cabinet body 1, the upper end of the cabinet body 1 is fixedly connected with a cooling table 12, one end of the cooling table 12 is provided with an air inlet 13, and the other end of the cooling table 12 is provided with an air outlet 14, and the air inlet The tuyere 13 and the air outlet 14 communicate with each other through the airflow passage, and the upper end of the cabinet body 1 is located at the position directly below the heat dissipation table 12. There are heat dissipation holes 2, and the heat dissipation holes 2 communicate with the airflow passage.

[0021] It should be noted that the diameter of the air inlet 13 is greater than the diameter of the air outlet 14, so when the airflow flows from the air inlet 13 to the air outlet 14, that is, when the airflow is in the airflow channel, its flow speed will increase significantly. According to fluid mechanics: "flui...

Embodiment 2

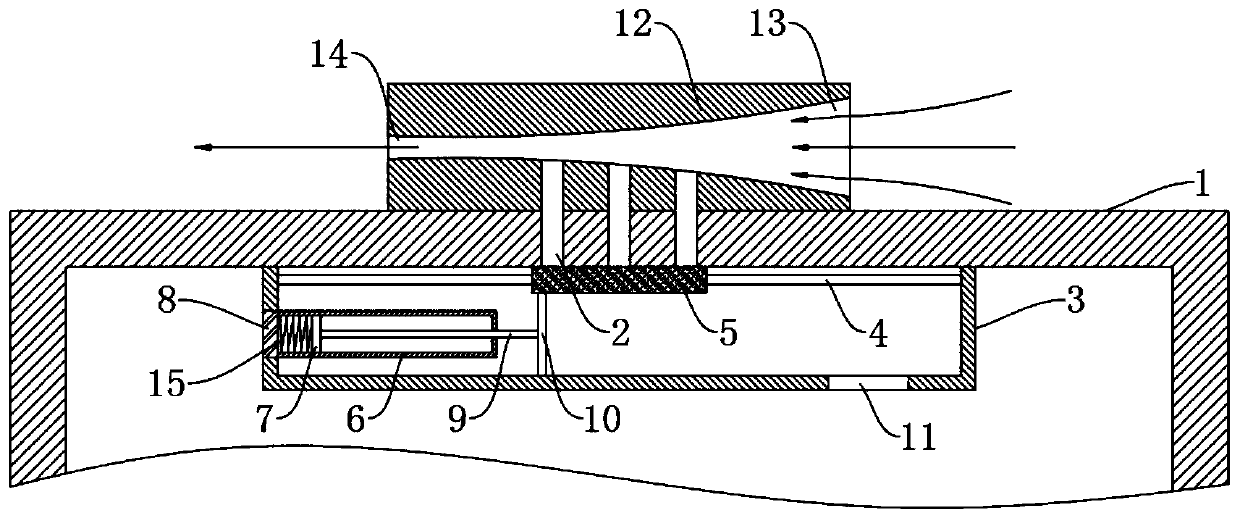

[0030] refer to image 3 , and the difference from Embodiment 1 is that: the thermally deformable metal 15 is fixedly connected between the heat conduction plate 8 and the slider 7, and the cavity between the inner wall of the slider cylinder 6 and the slider 7 is not filled with evaporating liquid.

[0031] It should be noted that the above-mentioned thermally deformable metal 15 adopts a two-way memory alloy, which is compressed into a folded shape at room temperature, and its minimum transformation temperature under hot air is 40°C, and nickel-titanium alloy or Cu can be used. - Zn-Al alloy. When the heat-deformed metal reaches the lowest transformation temperature, it will return to a straight strip, and when it is cooled below the transformation temperature, it can automatically change into a folded shape, and this process can be repeated.

[0032] In this embodiment, the heat-deformable metal 15 elongates when a high temperature is generated in the cabinet, thereby push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com