Gate valve with high sealing performance

A high-sealing, gate valve technology, applied in shaft seals, sliding valves, valve details, etc., can solve problems that affect the sealing performance of gate valves, difficult to open and close gate valves, and loss of sealing rings, and achieve the effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

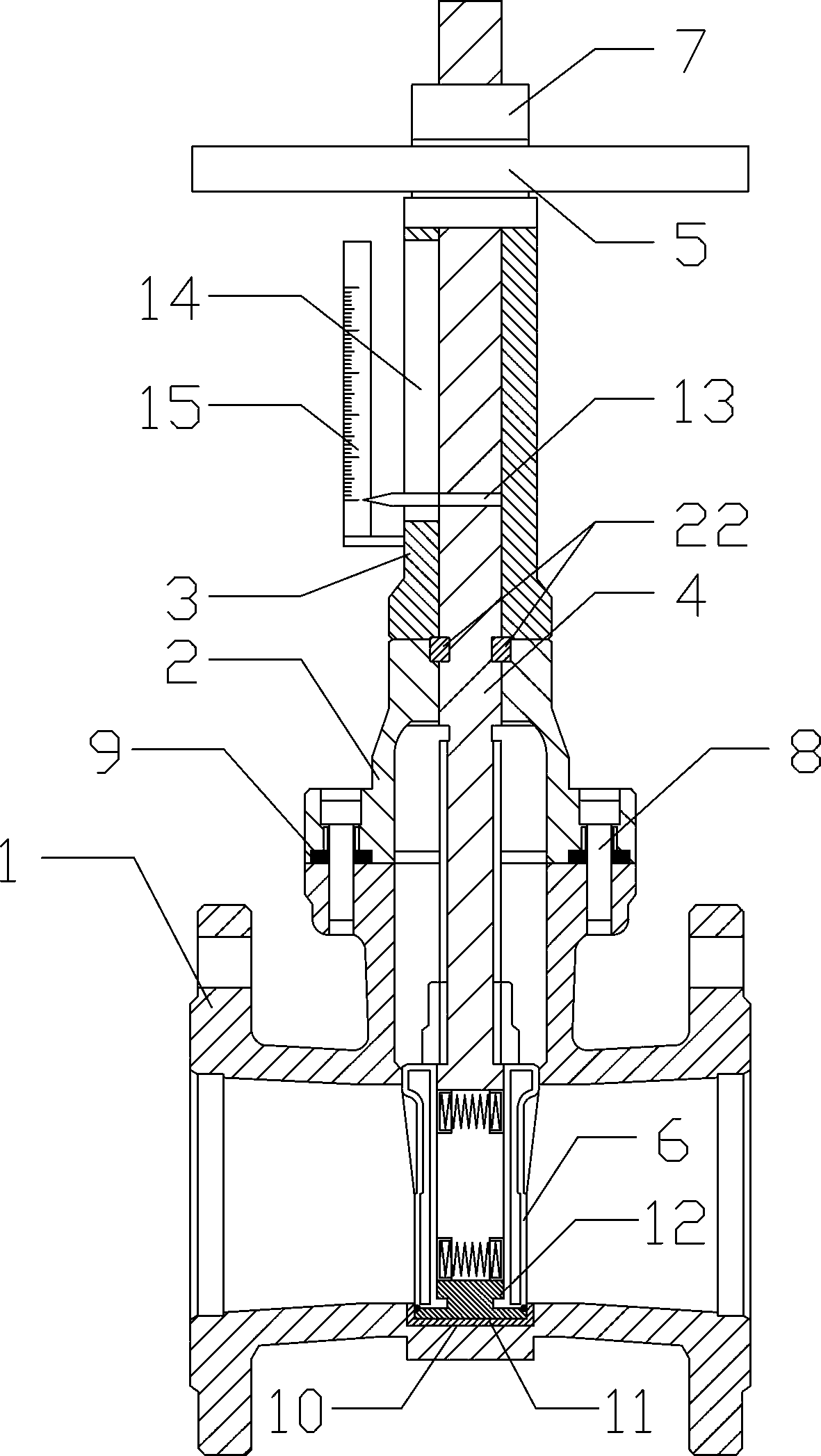

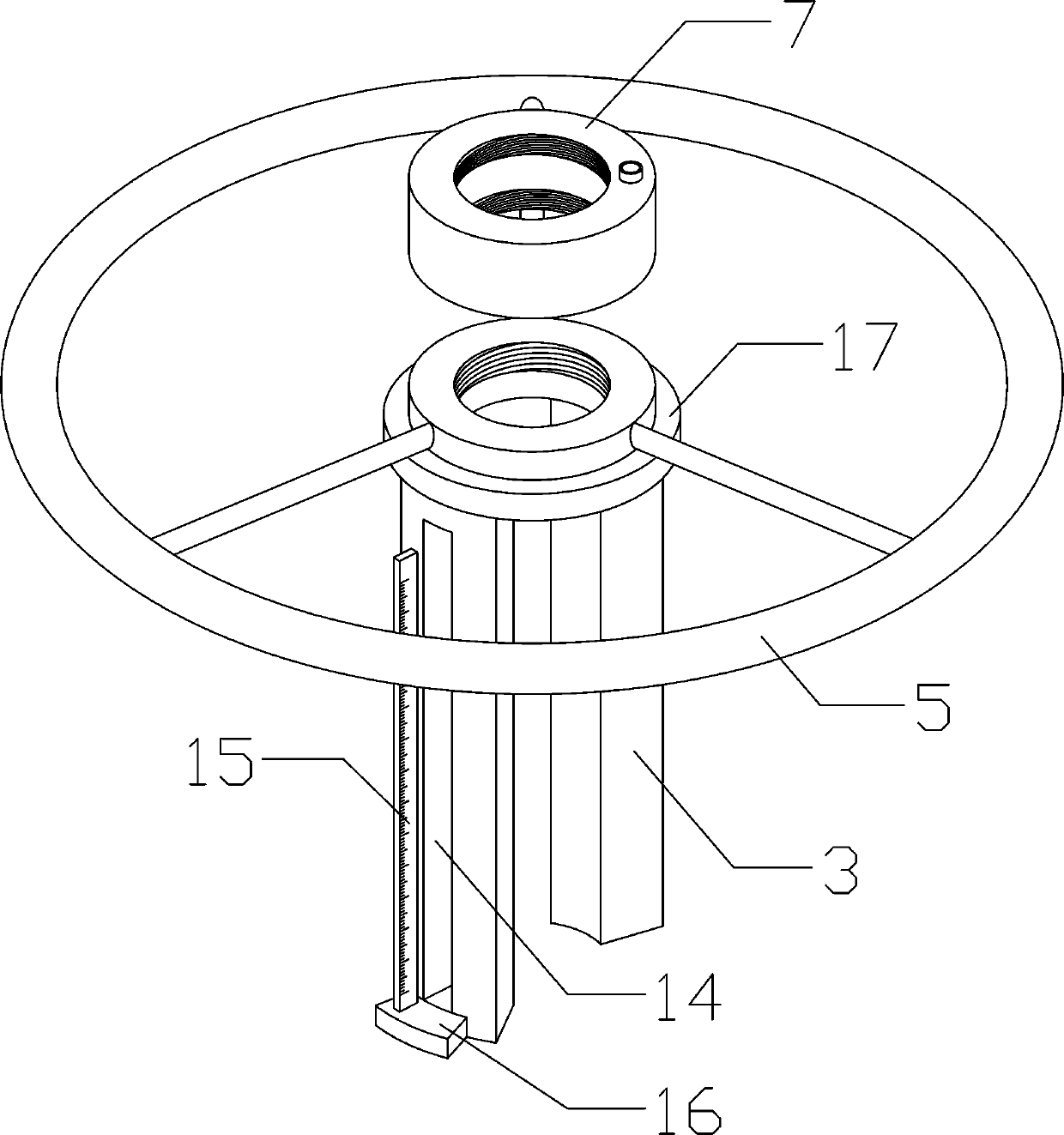

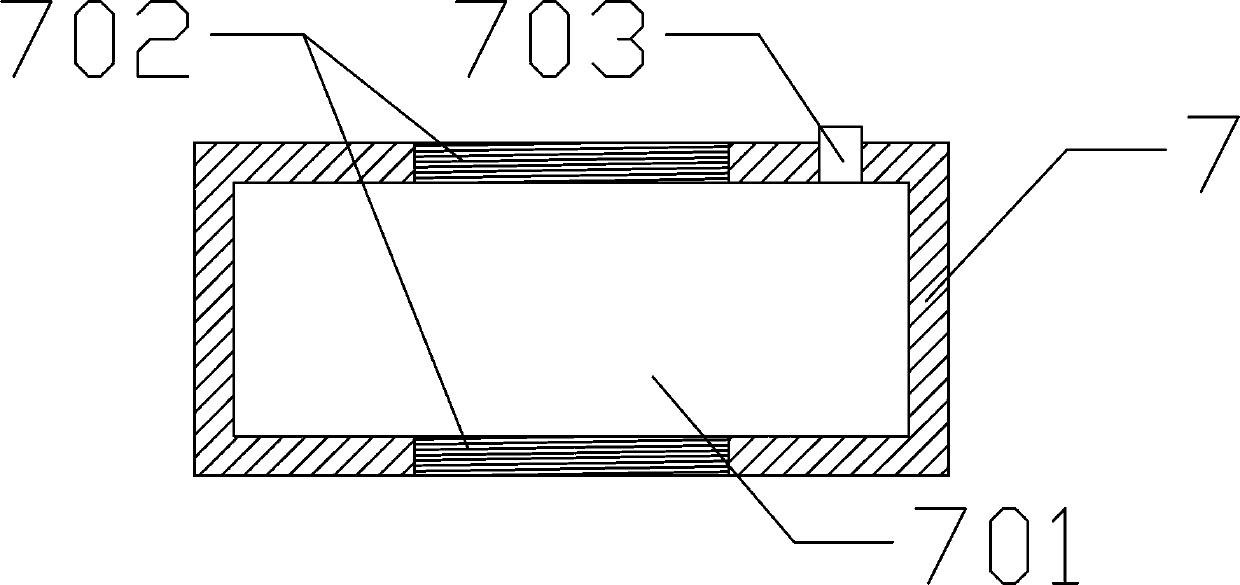

[0029] Such as Figure 1-6 Among them, a high-sealing gate valve includes a valve body 1, a valve cover 2 is arranged above the valve body 1, a bracket 3 is arranged above the valve cover 2, a handwheel 5 is arranged above the bracket 3, and the upper end of the valve stem 4 is connected with the handwheel 5. The lower end of the valve stem 4 passes through the bracket 3 and the bonnet 2 and then extends into the valve body 1. The lower end of the valve stem 4 in the valve body 1 is provided with a valve plate 6. On one side of the bracket 3 A strip-shaped through hole 14 is provided, an annular groove 401 is provided on a section of the valve stem 4 in the bracket 3, a pointer 13 is provided on the annular groove 401, and a support is provided on one side of the bracket 3 with the strip-shaped through hole 14. Block 16, the support block 16 is fixedly provided with a vertical scale rod 15, and one end of the pointer 13 passes through the bar-shaped through hole 14 and contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com