Channel type and static heating combined fuel oil heating structure

A heating structure and channel-type technology, applied in the direction of liquid fuel feeders, engine components, machines/engines, etc., can solve the problems of slow heat conduction process, low energy utilization rate, high energy waste rate, etc., and achieve high heating efficiency and improved The efficiency of assembly and disassembly and the effect of less energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

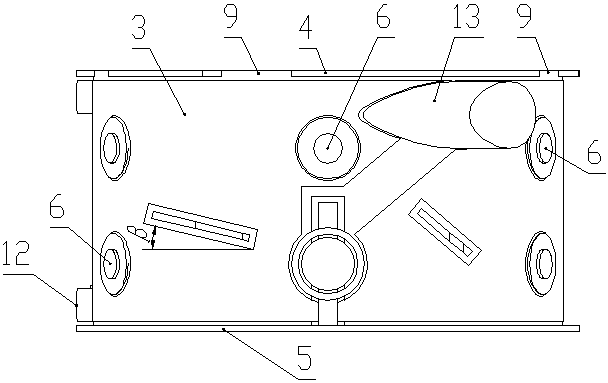

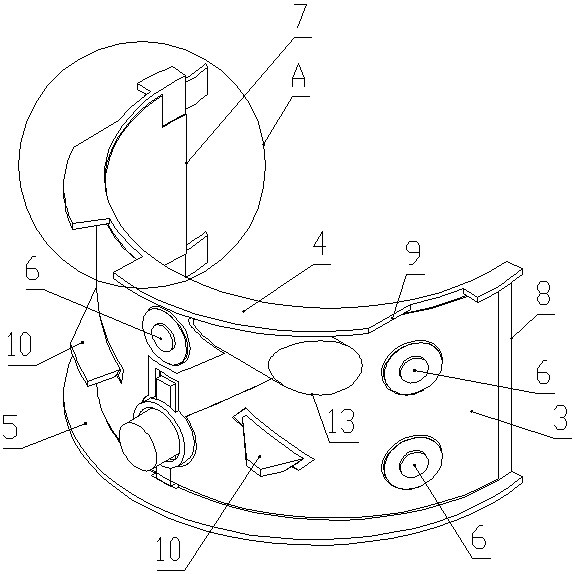

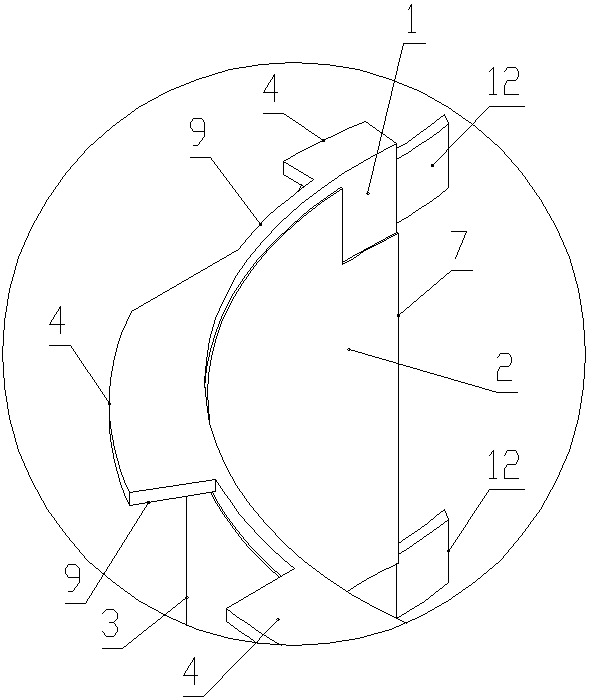

[0035] Such as Figure 1 to Figure 4 As shown, the fuel heating structure combining channel type and static heating of the present invention includes a middle vertical plate 1 with an arc-shaped horizontal section, with the side surface of the middle vertical plate 1 facing the center of its circle as the inner surface, and the other side surface as the outer surface. Surface; when installed in the fuel filter, the inner surface of the middle vertical plate 1 faces the filter element and its outer surface faces the housing of the fuel filter;

[0036] The inner surface of the middle vertical plate 1 is fitted and fixedly connected with the inner cooling plate 2, and the outer surface of the middle vertical plate 1 is fitted and fixedly connected with the outer cooling plate 3; the top of the middle vertical plate 1 is higher than the top of the outer cooling plate 3 and is connected with The upper support plate 4, the lower end of the middle vertical plate 1 is lower than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com