Integrated pump station preassembled dredging bottom tray and using method thereof

A pumping station and bottom basin technology, which is applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems such as the inability to remove the sludge in the cylinder of the integrated pumping station in time, and achieve high use and promotion value, convenient cleaning, and high degree of promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific embodiments.

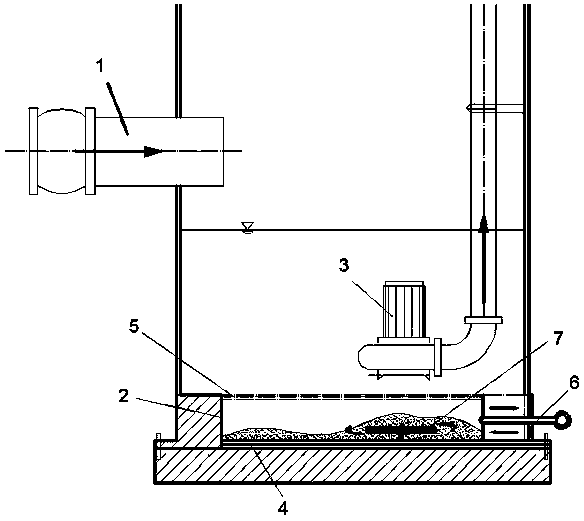

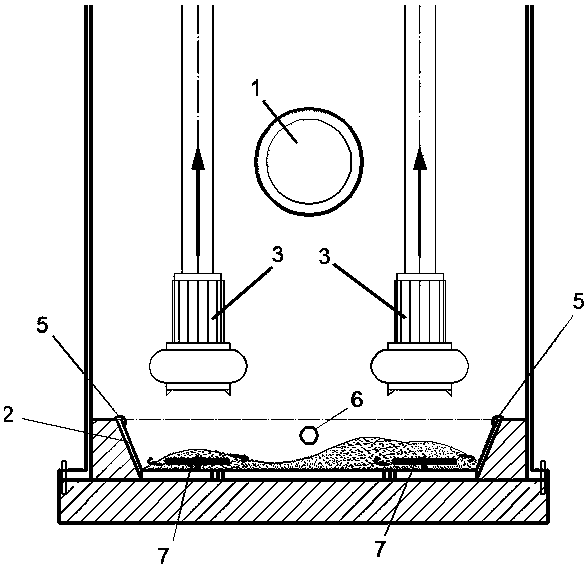

[0042]An integrated pumping station pre-installed dredging bottom basin, including a pumping station cylinder and a submersible sewage pump 3 arranged in the pumping station cylinder. The submersible sewage pump 3 is provided with a suction port and an outlet pipe, and the outlet pipe extends out of the pumping station. Cylinder; set the water inlet pipe 1 on one side of the pump station cylinder, and the water inlet pipe 1 passes through the pump station cylinder; set the dredging bottom basin 2 at the bottom of the pump station cylinder, and set A sludge stirring device 7, and the sludge stirring device 7 is located below the suction port of the submersible sewage pump 3.

[0043] Further, the bottom of the cylinder body of the pumping station is a wedge-shaped structure, and the dredging bottom basin 2 is a wedge-shaped structure matching the bottom of the pumping statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com