Inclined shaft ballastless track and construction method thereof

A ballastless track and inclined shaft technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of heavy maintenance workload, increased risk of rail transportation operations, and poor transportation operation efficiency, so as to speed up the construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

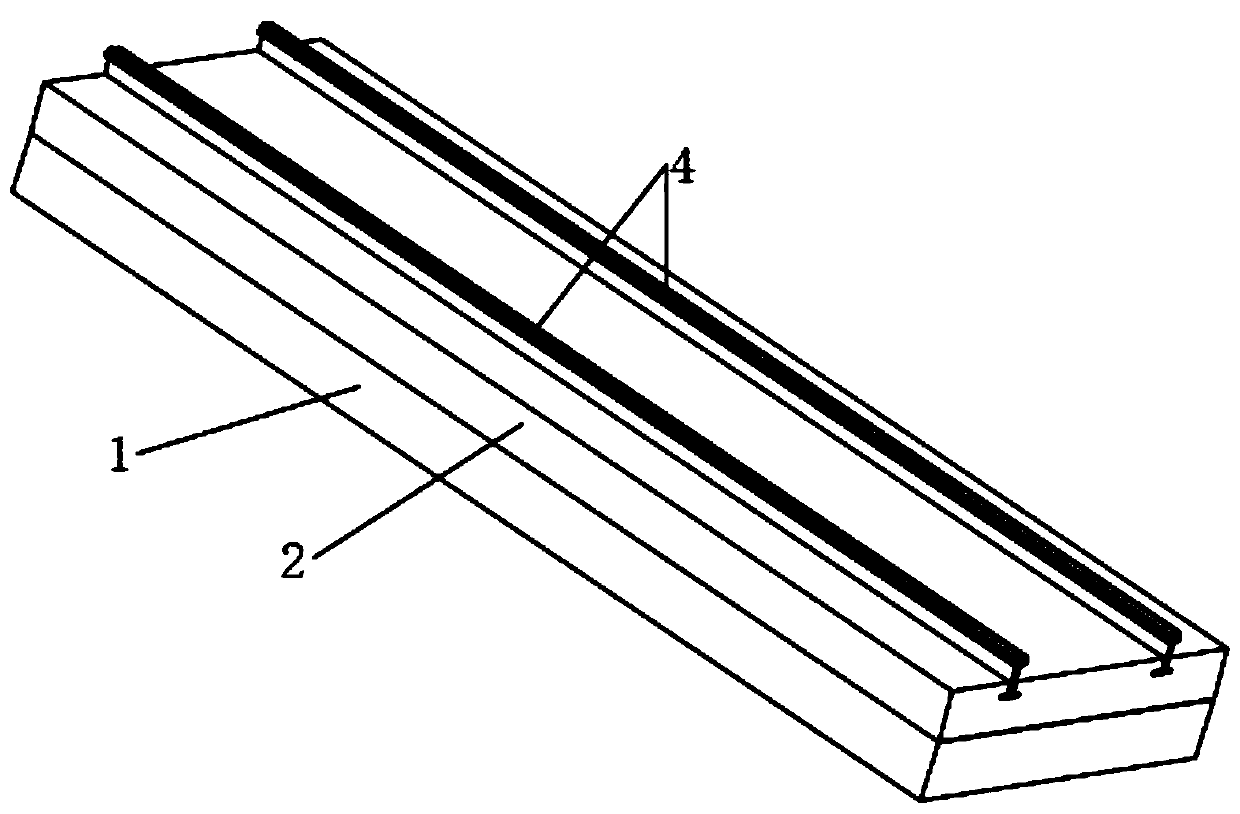

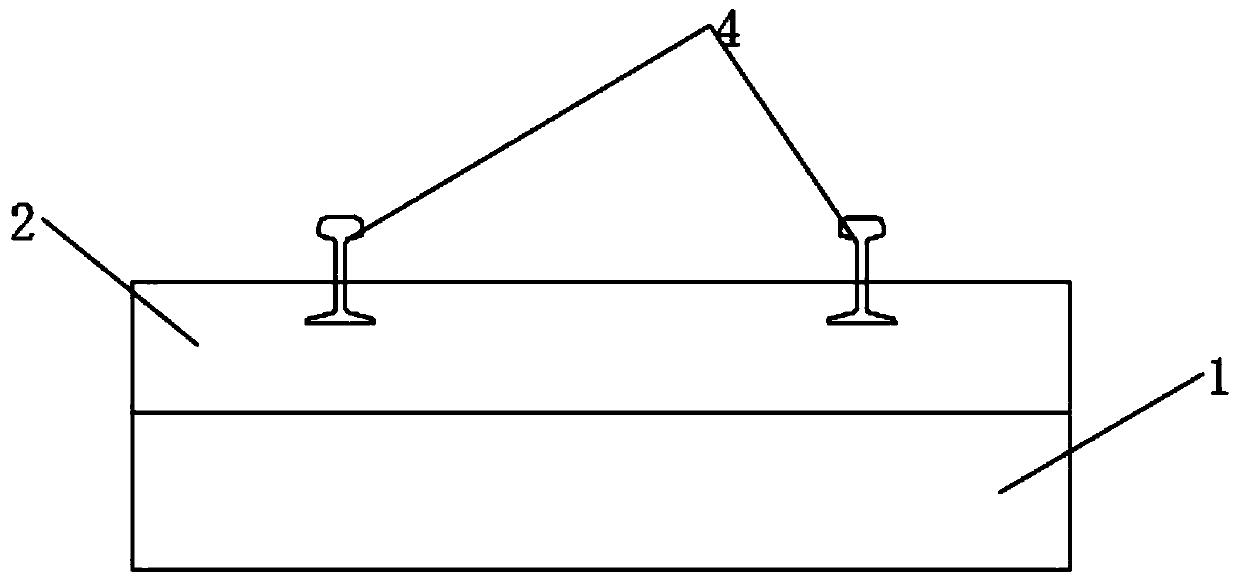

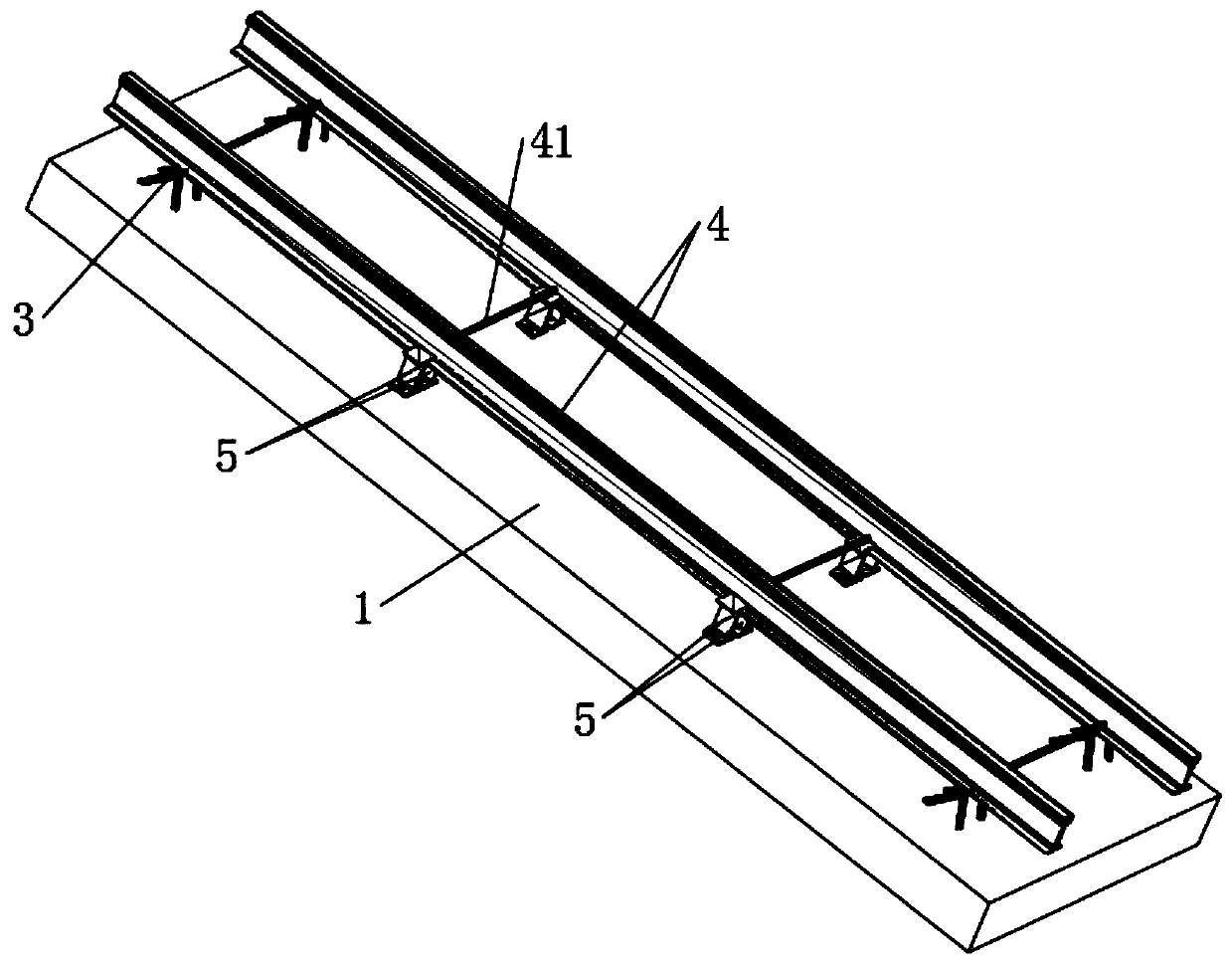

[0048] This embodiment provides an inclined shaft ballastless track, see Figure 1-6 , for viewing convenience, Figure 1-6 The track segments are all shown, the inclined shaft ballastless track includes a ballast bed 2, the ballast bed 2 is poured with concrete, and the ballast bed 2 is arranged on the bottom plate of the inclined shaft 1, which is the lower bottom of the inclined shaft On the slope surface, the ballast bed 2 is provided with a number of sleepers 3 and a number of stoppers 5, all of the sleepers 3 are used to support the rail 4, the lower part of the rail 4 is embedded in the ballast bed 2, and the stopper 5. One end is connected to the bottom plate of the inclined shaft 1, and the other end is connected to the steel rail 4.

[0049] In this embodiment, all the sleepers 3 include two rows arranged symmetrically, each row of sleepers 3 is connected to the bottom plate 1 of the inclined shaft at intervals along the longitudinal direction of the inclined shaft,...

Embodiment 2

[0056] This embodiment provides a construction method of the inclined shaft ballastless track as described in Embodiment 1, comprising the following steps:

[0057] Step 1: According to the design, stake out the track line on the bottom plate of the inclined shaft 1, and set the sleeper 3 on the bottom plate 1 of the inclined shaft according to the track line;

[0058] Step 2: laying two steel rails 4 on the corresponding sleepers 3 respectively;

[0059] Step 3: Connect several limiting parts 5 between the rail 4 and the bottom plate of the inclined shaft 1;

[0060] Step 4: Close the track bed formwork, pour the track bed 2, place the lower part of the rail 4, the sleeper 3 and the stopper 5 in the track bed 2, and the construction of the inclined shaft ballastless track is completed.

[0061] Specifically, the bottom surface of the inclined shaft is first leveled and cleaned to form the bottom plate 1 of the inclined shaft; in order to ensure the pouring quality of the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com