Ammonia water combined with ultrasonic extraction method and system for polyhydroxyalkanoate

A polyhydroxyalkanoate and ultrasonic technology, which is applied in the field of ammonia water combined with ultrasonic extraction of polyhydroxyalkanoates, can solve the problems of high production cost, low PHA polymerization degree, low PHA purity and yield, etc. The effect of mitigating degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

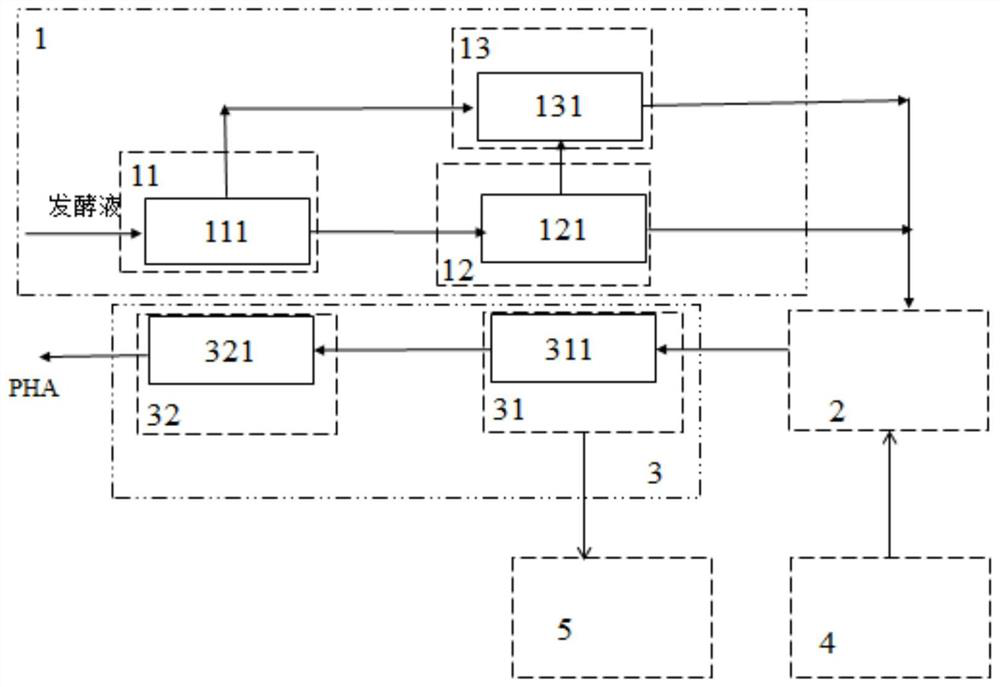

Image

Examples

Embodiment approach

[0067] In the present invention, the fermentation broth of the polyhydroxyalkanoate can be the fermentation broth of microorganisms that can be used to prepare polyhydroxyalkanoate conventionally in the art. Preferably, the microorganism is a halophilic bacterium, for example, it can be a salt One of the genus Monas, according to a preferred embodiment of the present invention, the PHA fermentation strain is Halomonas sp.; more preferably, the PHA fermentation strain is Halomonas sp. Bacteria (Halomonas sp.) TD01, its preservation number is CGMCC NO.4353 (CN201010578858.8).

[0068] In the present invention, the fermentation medium used for the fermentation of the polyhydroxyalkanoate is not particularly limited, and may be a conventionally used fermentation medium in the art, and will not be repeated here.

[0069] In the present invention, the conditions for the fermentation of the polyhydroxyalkanoate are not particularly limited, and may be conventionally used fermentation...

preparation example 1

[0104] Halomonas (TD01, whose preservation number is CGMCC NO.4353 (CN201010578858.8)) was inoculated in the seed medium (yeast powder of 5g / L, peptone of 10g / L and sodium chloride of 60g / L) Under the conditions of 37°C and 200rpm, carry out primary activation culture, culture to OD 600 Reach about 4, obtain first-grade seed liquid;

[0105] Inoculate the primary seed liquid into the seed medium with an inoculation amount of 10% by volume, carry out secondary activation culture at 37°C and 200rpm, and cultivate to OD 600 Reach about 4, obtain secondary seed liquid, obtain fermented seed liquid.

[0106] Then the inoculum of 10 volume % is inserted into the initial fermentation medium (sodium chloride 50g / L, glucose 50g / L, corn steep liquor powder 15g / L, urea 2g / L, magnesium sulfate 0.2g / L) L, potassium dihydrogen phosphate 5g / L, trace element mother liquid I 10mL / L, trace element mother liquid II 3mL / L. The trace element mother liquid I and II refer to the cited patent CN201...

Embodiment 1

[0108] (1) The polyhydroxyalkanoate fermented liquid prepared in Preparation Example 1 is centrifuged through a disc centrifuge, so that the fermented liquid is divided into an underflow (water content 90% by weight) rich in bacterial cells (the first bacterial cell ) and the fermentation raffinate top flow (the first fermentation raffinate), and the fermentation raffinate top flow enters the fermentation raffinate temporary storage tank.

[0109] (2) the underflow that is rich in the target thalline cell that step (1) obtains is washed 2 times with equal volume of water, then pumped into a belt vacuum filter and filtered, and the thalline (water content 75% by weight) after the filter is dried %) (the second bacterial cell) enters the ultrasonic-assisted extraction tank, and the filtrate (second fermentation raffinate) enters the fermentation raffinate temporary storage tank.

[0110] (3) pump the mixed solution of the fermentation raffinate and the filtrate in the temporary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com