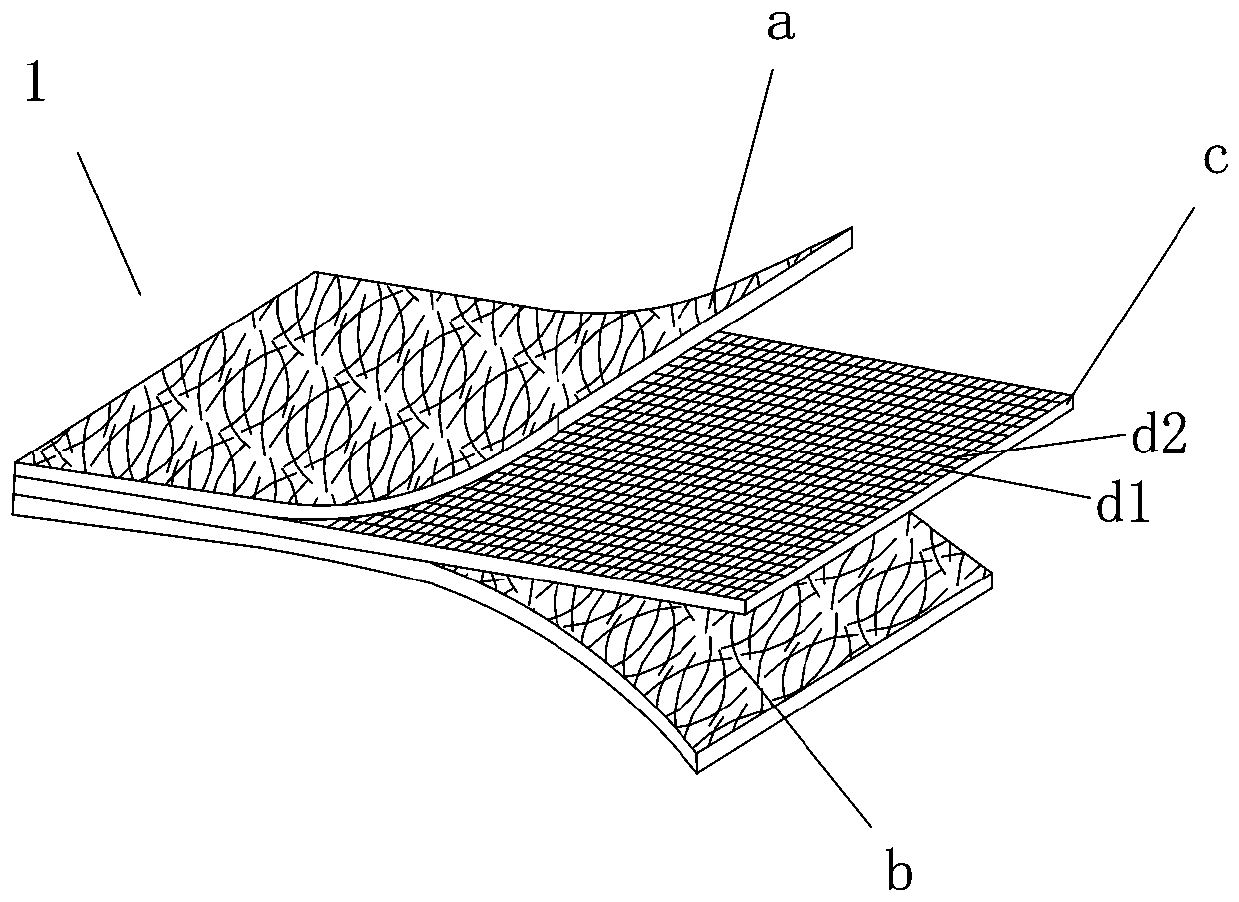

Elastic composite nonwoven fabric and manufacturing method thereof

A manufacturing method and technology of non-woven fabrics, applied in textiles and papermaking, chemical instruments and methods, non-woven fabrics, etc., to achieve the effects of preventing breakage, soft touch, and preventing pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as image 3 and cooperate figure 1 , figure 2 Shown, elastic composite nonwoven fabric of the present invention adopts following manufacture method:

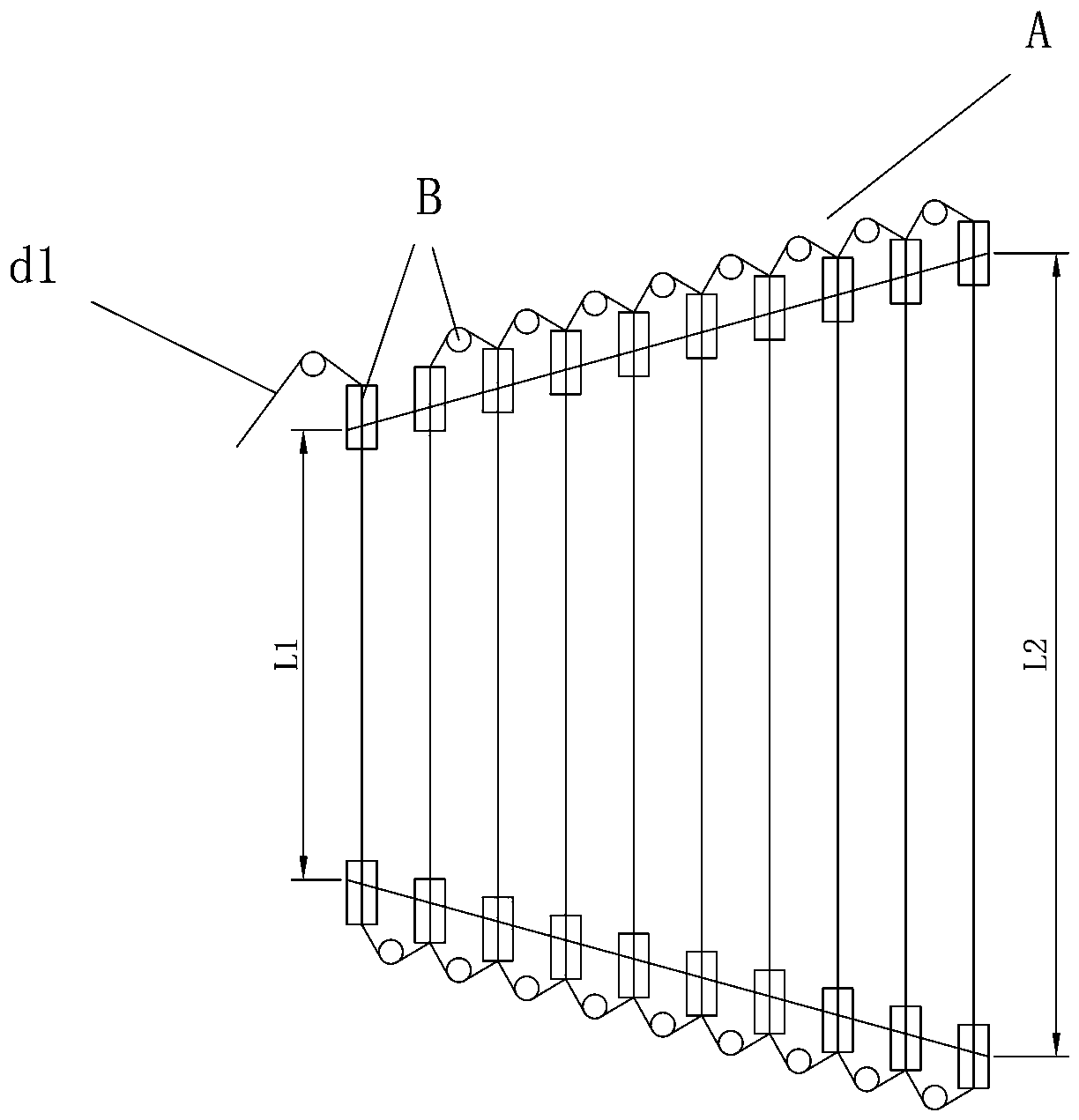

[0060] (1) The supply process of horizontally arranged spandex yarns: after unwinding the horizontally arranged spandex yarns d1, they are wound on multiple sets of godet wheels B1 located at both ends of the transverse stretching device A1 to form a horizontally arranged spandex mesh. The starting end of the transverse stretching device runs towards the end of the transverse stretching device, and the ratio of the lateral distance L2 of the terminal end of the transverse stretching device to the transverse distance L1 of the starting end of the transverse stretching device is 1.8. The starting end of the horizontal stretching device is gradually stretched when it runs towards the terminal end of the transverse stretching device. When it reaches the position where the terminal end of the transverse stretching devi...

Embodiment 2

[0066] Such as image 3 ,Cooperate figure 1 , figure 2 As shown, the elastic composite nonwoven fabric of the present invention adopts the following manufacturing method:

[0067] (1) The supply process of horizontally arranged spandex yarns: After unwinding the horizontally arranged spandex yarns d1, they are wound on multiple sets of godet wheels B2 located at both ends of the transverse stretching device A2 to form a horizontally arranged spandex mesh. The starting end of the transverse stretching device runs toward the terminal end of the transverse stretching device, and the ratio of the lateral distance L2 of the terminal end of the transverse stretching device to the transverse distance L1 of the starting end of the transverse stretching device is 2.5, so the transversely arranged spandex filaments d1 are formed by the transverse stretching device The starting end of the horizontal stretching device is gradually stretched when it runs towards the terminal end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com