Gauze mask ear band welding machine

A welding machine and ear strap technology, which is applied to household components, tools for sewing clothes, household utensils, etc., can solve problems such as low production efficiency and achieve the effect of convenient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: the concrete structure of the present invention is as follows:

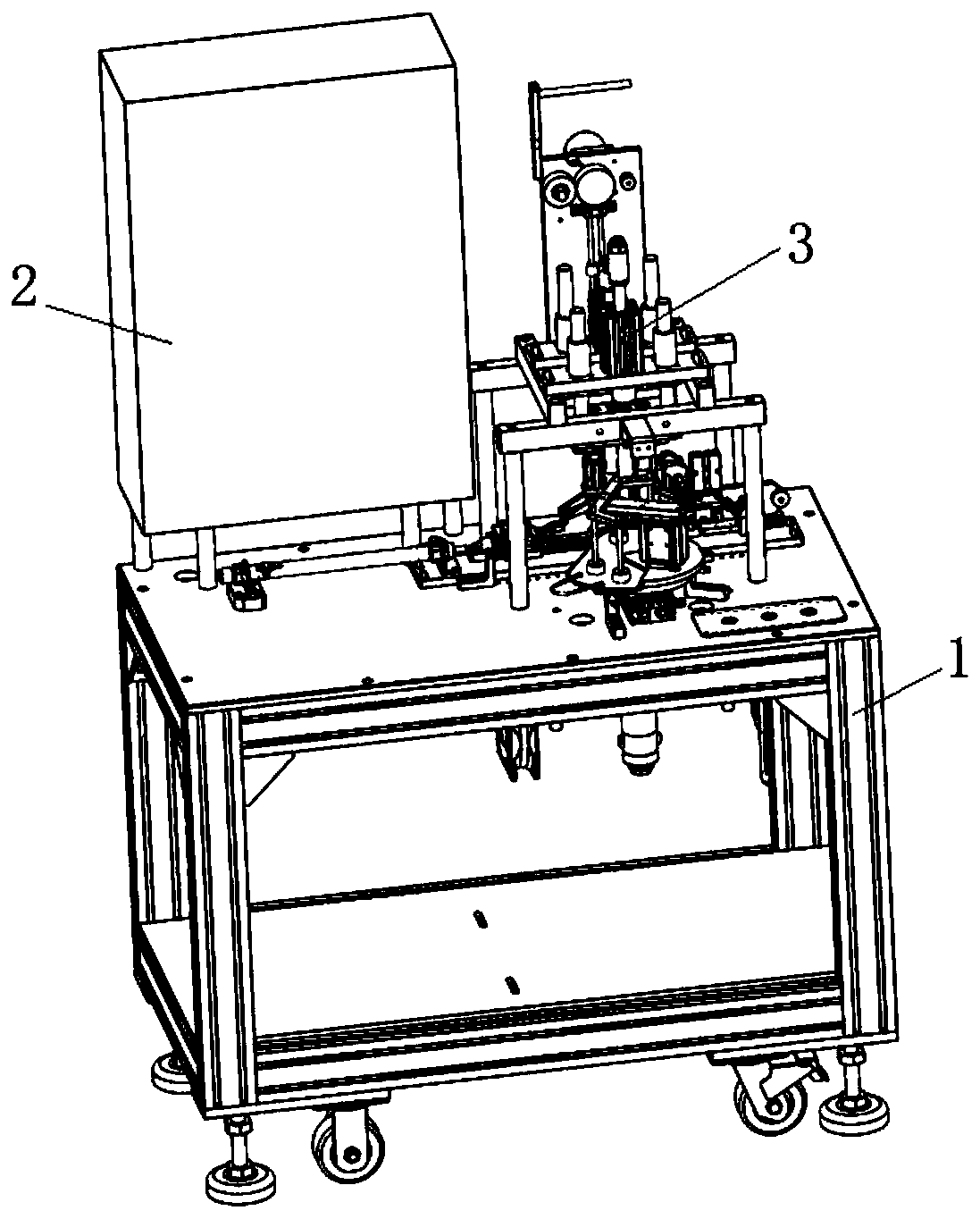

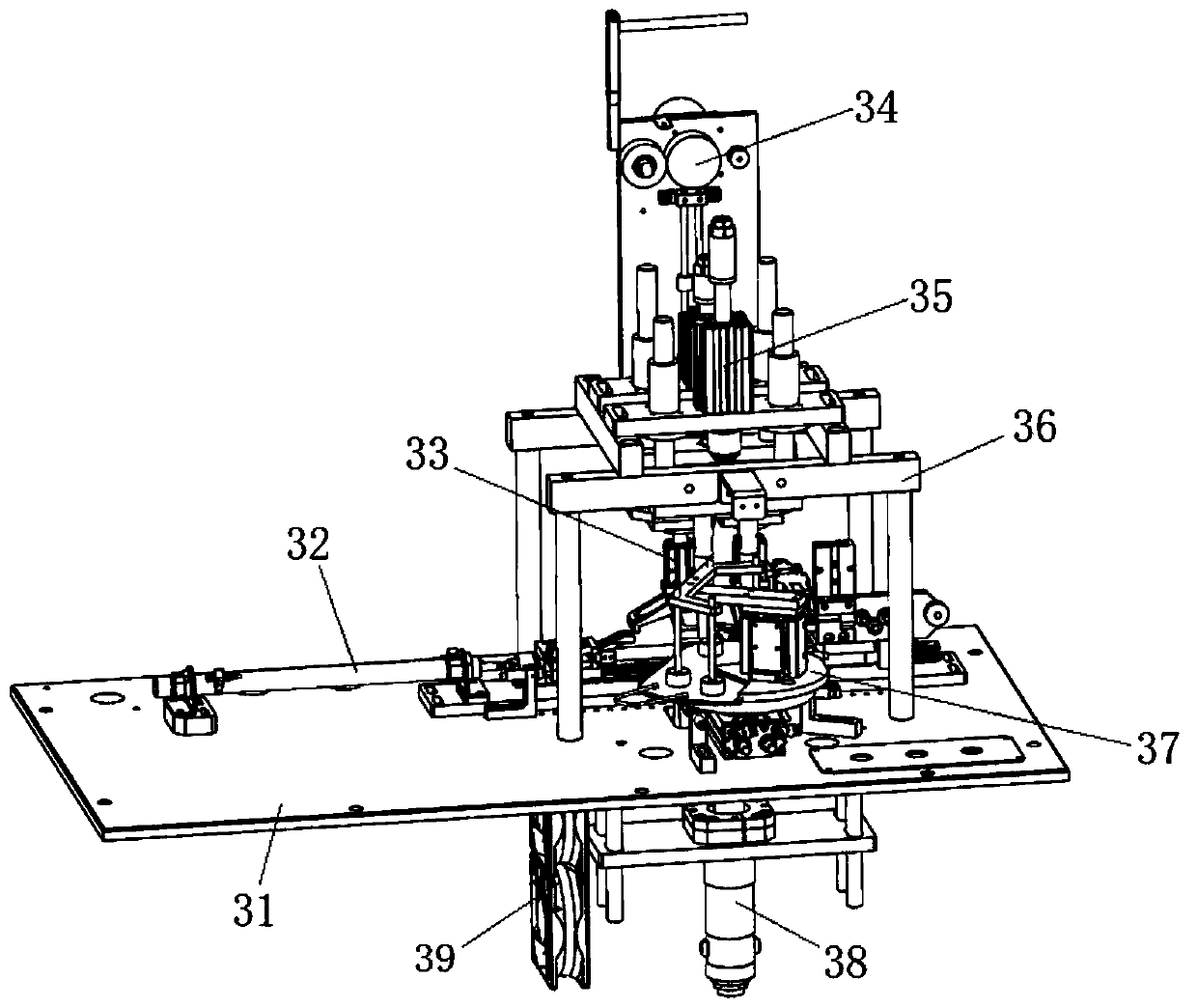

[0057] Please refer to the attached Figure 1-9 , a mask earband welding machine of the present invention, comprising a frame 1 with a platen 31 at the top, a welding device 3 arranged on the upper surface of the platen 31 and a control box for controlling the automatic operation of the welding device 3 2. The welding device 3 includes:

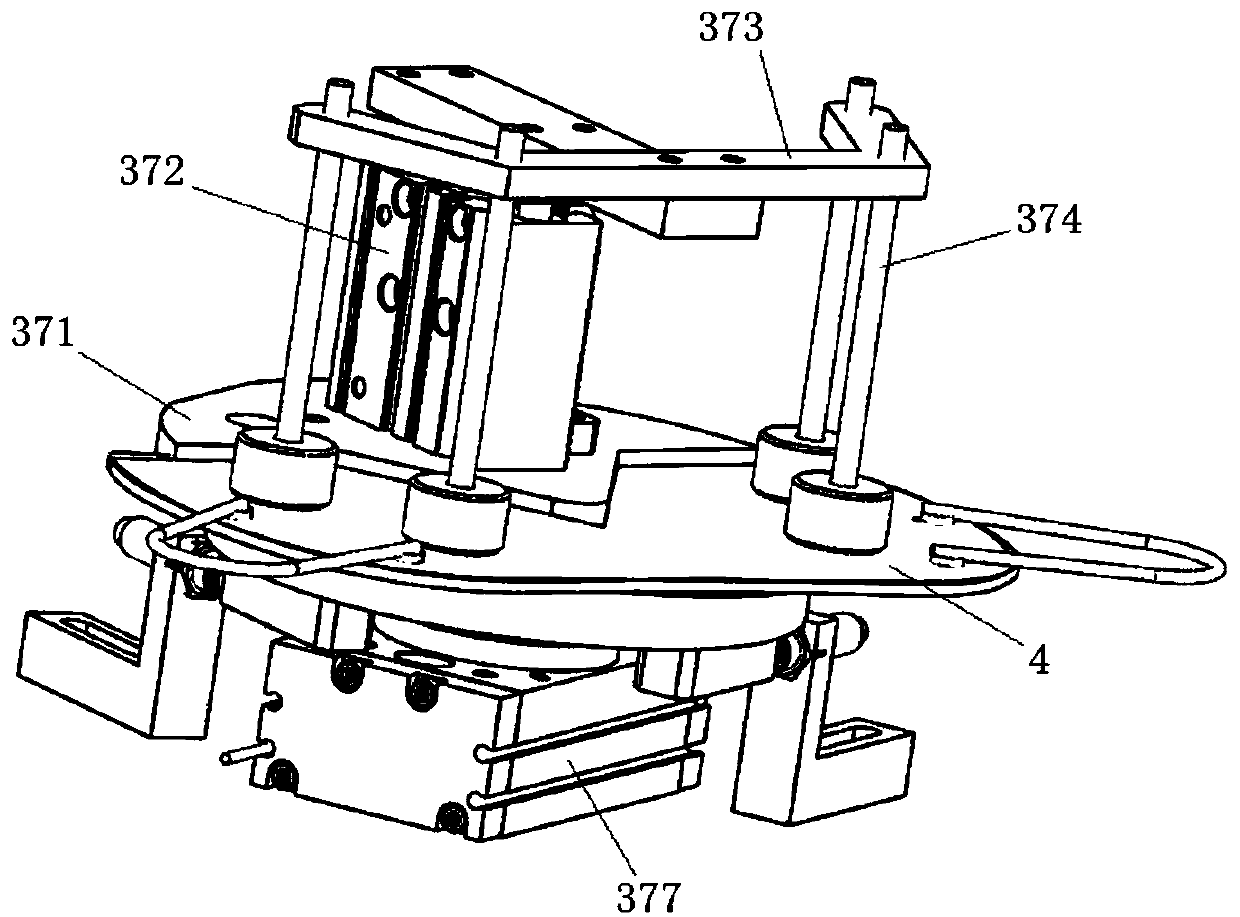

[0058] Feeding mechanism 37, it is provided with the first rotating mechanism that is fixed on described platen 31 and is installed on described first rotating mechanism and is driven by described first rotating mechanism to do the mouth mask feeding platform of rotating action 371, one side of the table top of the mask feeding table 371 is fixed with a pressing mechanism, and the other side of the table top is provided with a mask sleeve setting part 3711;

[0059] A conveying mechanism 34 for storing the ear strap reel and conveying the ear strap, the co...

Embodiment 2

[0087] The operating principle of the mask earband welding machine of the present invention:

[0088] In the initial state, the mask sleeve part 3711 faces the feeding side and faces the manual feeding direction.

[0089] Step 1, the compression mechanism is opened, the mask body is put on the mask sleeve part 3711, the first lifting cylinder 372 on the compression mechanism drives the compression bracket 373 to descend, and the compression rod assembly 374 descends with the compression bracket 373 And press the mask body tightly.

[0090] Step 2, the rotating cylinder 377 drives the mask feeding table to rotate at an angle, so that the mask sleeve part 3711 enters the welding place.

[0091] Step 3, the delivery mechanism 34 transports the ear straps to the ear strap introduction part 324, so that the ear straps enter the wire slot and expose a section outside the wire slot.

[0092] Step 4, the cylinder for pulling ear straps is driven by the linear cylinder 327 to the exp...

Embodiment 3

[0103] The side edge of the bottom mounting plate 321 on the pulling and cutting mechanism 32 of the present invention is provided with two sensing parts, the two sensing parts limit the running distance of the linear cylinder 327, and then determine the length of the ear strap line, and the positions of the two sensing parts can be adjusted , specifically, a row of adjustment holes is provided on the platen 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com