Preparation method of chenopodium quinoa willd and highland barley ferment powder

A technology of enzyme powder and quinoa, applied in the direction of bacteria used in food preparation, functions of food ingredients, food science, etc., can solve problems such as difficult transportation and complicated packaging, so as to facilitate digestion and absorption, increase the number of live bacteria in the product, The effect of high nutrition and health care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of quinoa and highland barley enzyme powder, comprising the following steps:

[0036] (1) Quinoa and highland barley seeds: selection and removal of impurities;

[0037] (2) Sterilization: Soak a certain amount of highland barley and quinoa seeds with 0.1% sodium hypochlorite at a solid-to-liquid ratio of 1:4, and rinse them three times with drinking water after 30 minutes of sterilization;

[0038] (3) Soaking: then soak the sterilized quinoa and highland barley seeds at 25°C for 2 and 9 hours respectively, so that the moisture content in the material reaches about 40%;

[0039] (4) Germination: Drain the excess water, and germinate under the condition of constant temperature and humidity at 25°C and avoid light. The germination time of quinoa and highland barley is 24h and 36h respectively;

[0040] (5) Drying: the germinated seeds are first dried with hot air at a lower temperature to a moisture content of about 15%, then heated and dried to a m...

Embodiment 2

[0047] A preparation method of quinoa and highland barley enzyme powder, comprising the following steps:

[0048] (1) Quinoa and barley seeds: selection and removal of impurities.

[0049] (2) Sterilization: Soak a certain amount of highland barley and quinoa seeds with 0.1% sodium hypochlorite at a solid-to-liquid ratio of 1:4, sterilize for 30 minutes, and then wash.

[0050] (3) Soaking: then soak the sterilized quinoa and highland barley seeds at 25°C for 2h and 9h respectively, so that the moisture content in the material reaches about 40%;

[0051] (4) Germination: Drain excess water, and germinate under the condition of constant temperature and humidity at 25°C and avoid light. The germination time of quinoa and highland barley is 24 and 36 hours respectively.

[0052] (5) Drying: The germinated seeds are first dried with hot air at a lower temperature to a moisture content of about 15%, then heated and dried to a moisture content of about 5%, and ground for later use....

Embodiment 3

[0058] Embodiment 3: the optimization of germination condition

[0059] 1. Optimization of quinoa seed germination conditions

[0060] Prepare quinoa malt with reference to the method of Example 1, set different soaking times, other conditions are the same as Example 1, the results are shown in figure 1 . Depend on figure 1 It can be seen that the content of γ-aminobutyric acid is the highest when soaked for 2 hours.

[0061] Prepare quinoa malt with reference to the method of Example 1, set different germination times, other conditions are the same as Example 1, the results are shown in figure 2 . Depend on figure 2 It can be seen that the content of γ-aminobutyric acid is the highest at 24 hours of germination.

[0062] 2. Optimization of Germination Conditions for Highland Barley Seeds

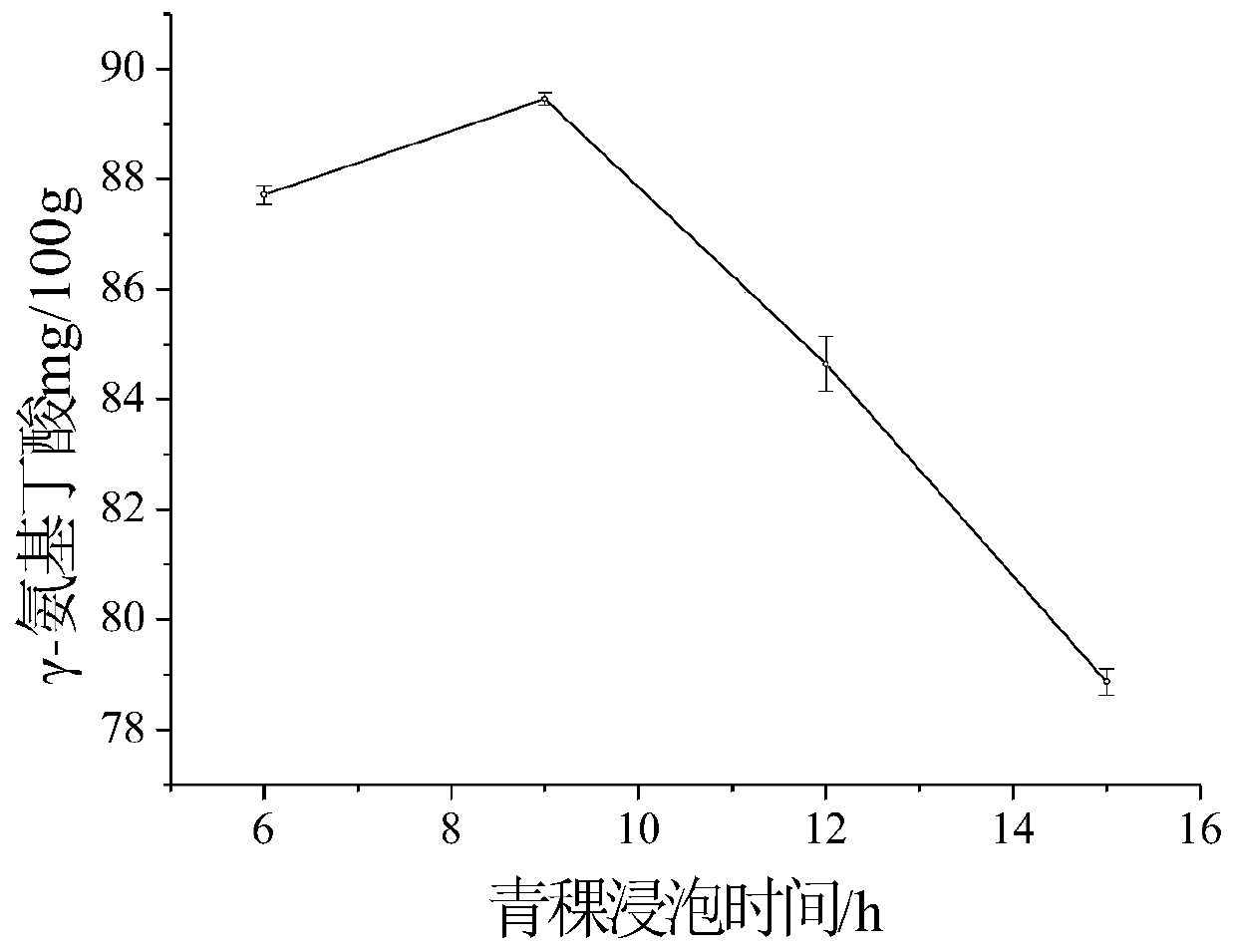

[0063] Prepare highland barley malt with reference to the method of Example 1, set different soaking times, other conditions are the same as Example 1, the results are shown in i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com