A kind of high temperature resistant samarium cobalt permanent magnet and preparation method thereof

A permanent magnet, high temperature resistant technology, used in the manufacture of permanent magnets, magnets, permanent magnets, etc. It can solve the problems of applications that cannot meet high temperature, the magnetic field of samarium cobalt permanent magnets is unstable, and cannot be used in high temperature applications, and achieve excellent anti-corrosion. effect, excellent high temperature resistance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing the high-temperature-resistant samarium-cobalt permanent magnet described in the above technical solution, comprising the following steps:

[0029] Plating copper on the surface of the samarium cobalt permanent magnet substrate to obtain a samarium cobalt permanent magnet covered with copper plating;

[0030] A nano-carbon material layer is deposited on the surface of the samarium-cobalt permanent magnet covered with copper plating to obtain a high-temperature-resistant samarium-cobalt permanent magnet.

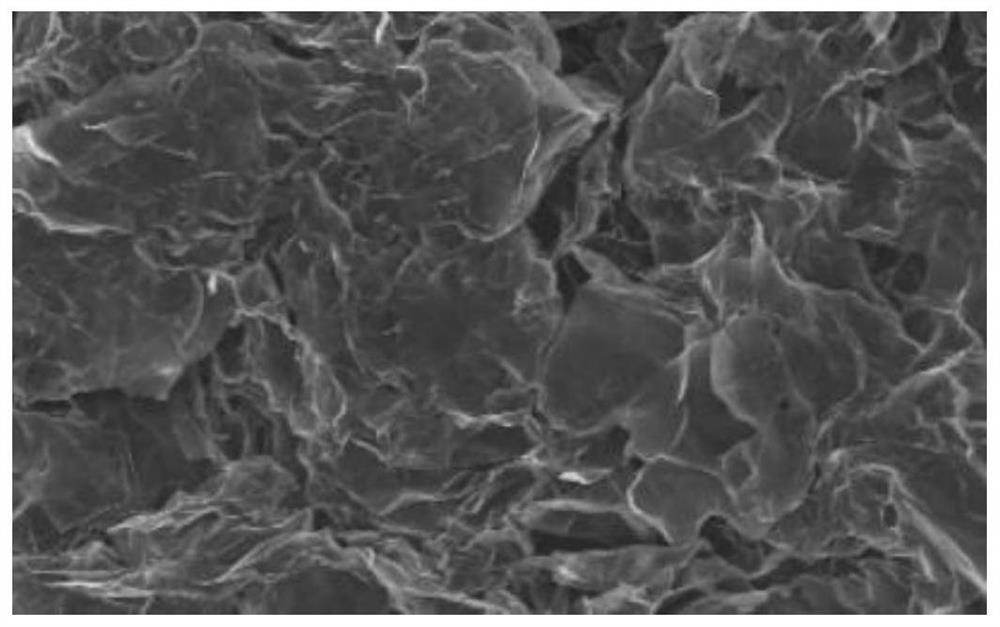

[0031] In the invention, copper is plated on the surface of the samarium-cobalt permanent magnet substrate to obtain the samarium-cobalt permanent magnet covered with the copper coating. The present invention has no special limitation on the preparation method of the samarium-cobalt permanent magnet matrix, and the preparation method of the samarium-cobalt permanent magnet well-known in the art can be adopted, and s...

Embodiment 1

[0040] Referring to the preparation method of Chinese patent CN107316726A embodiment 6, a samarium-cobalt permanent magnet substrate is prepared, wherein the molar ratio of samarium-cobalt is 2:17;

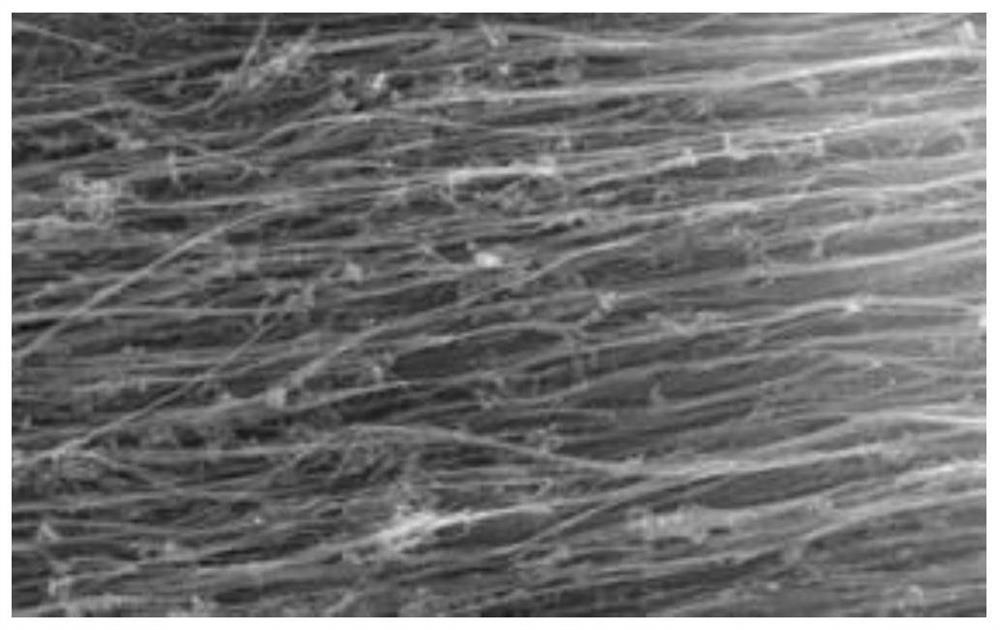

[0041]With reference to the method of Chinese Patent CN101405435B Example 1, copper-plate the surface of the samarium-cobalt permanent magnet substrate to obtain a copper coating. The size of the copper particles in the copper coating is 10-20 nm, and the thickness of the copper coating is 25 μm; Methane was introduced, water vapor was introduced at a rate of 1L / min, protected by high-purity argon, and chemical vapor deposition was carried out at 850°C to obtain a nano-carbon material layer. The thickness of the nano-carbon material layer was 60 μm. High temperature samarium cobalt permanent magnet.

[0042] The service temperature range of the obtained high-temperature-resistant samarium-cobalt permanent magnet is -50 to 500°C, and the salt spray resistance time is 180h (the test...

Embodiment 2

[0044] Referring to the preparation method of Chinese patent CN107316726A embodiment 6, a samarium-cobalt permanent magnet substrate is prepared, wherein the molar ratio of samarium-cobalt is 2:17;

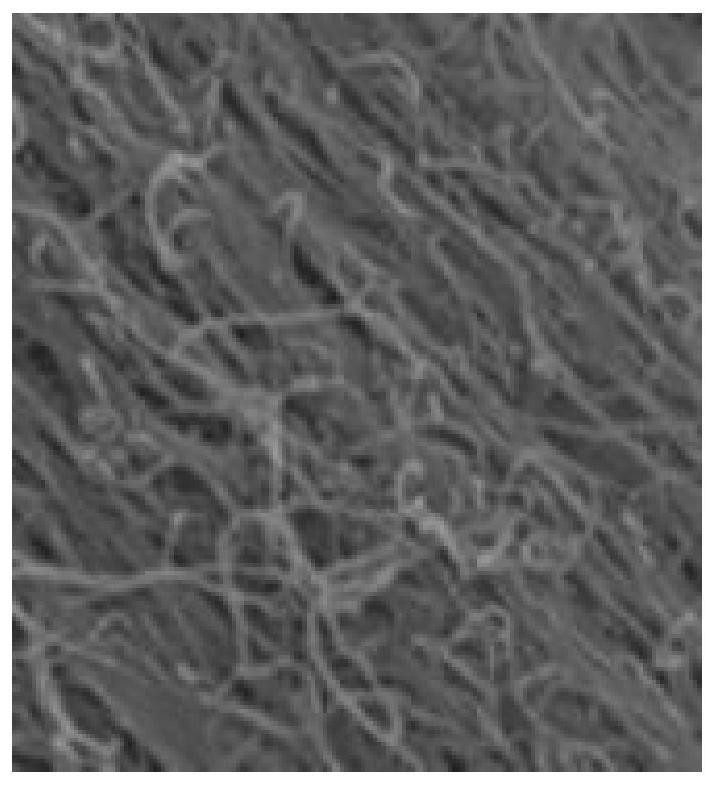

[0045] With reference to the method of Chinese Patent CN101405435B Example 1, copper-plate the surface of the samarium-cobalt permanent magnet substrate to obtain a copper coating. The size of the copper particles in the copper coating is 5 nm, and the thickness of the copper coating is 20 μm; Acetylene was fed with water vapor at a rate of 2L / min, protected by high-purity nitrogen, and chemical vapor deposition was carried out at 850°C to obtain a nano-carbon material layer. The thickness of the nano-carbon material layer was 80 μm, and a high-temperature resistant samarium cobalt was prepared Permanent magnets.

[0046] The service temperature range of the obtained high-temperature-resistant samarium-cobalt permanent magnet is -40 to 600°C, and the salt spray resistance time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com