Control method and control apparatus of linear motor stage

A linear motor and control device technology, applied in the direction of AC motor control, electric controller, controller with specific characteristics, etc., can solve problems such as difficult to achieve, achieve high-precision and high-speed positioning, easy adjustment, and realization of the design process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail based on drawings showing its embodiments.

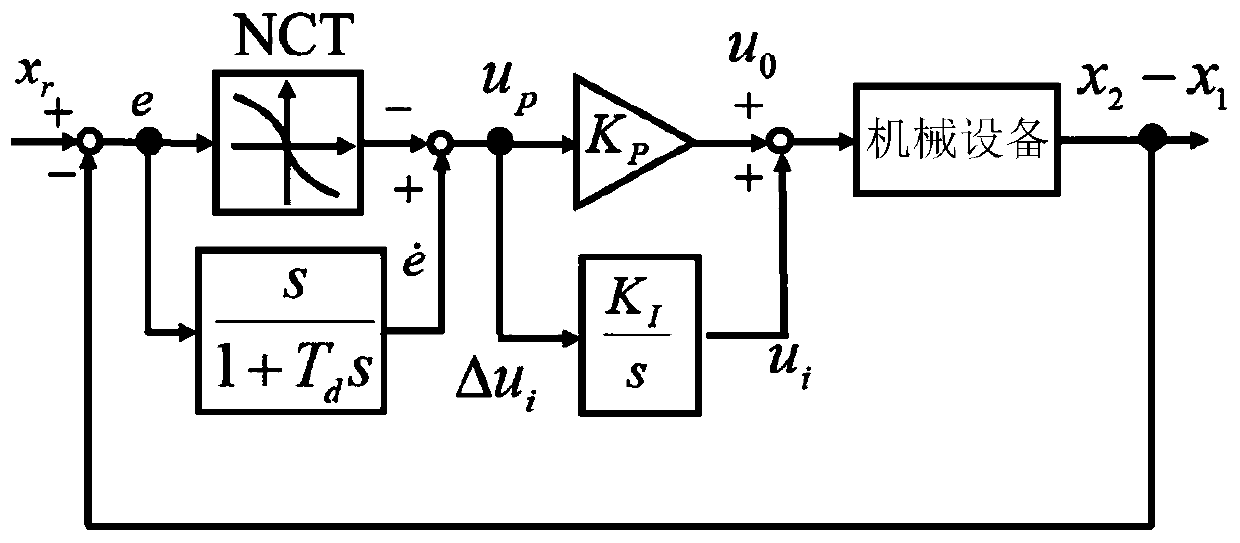

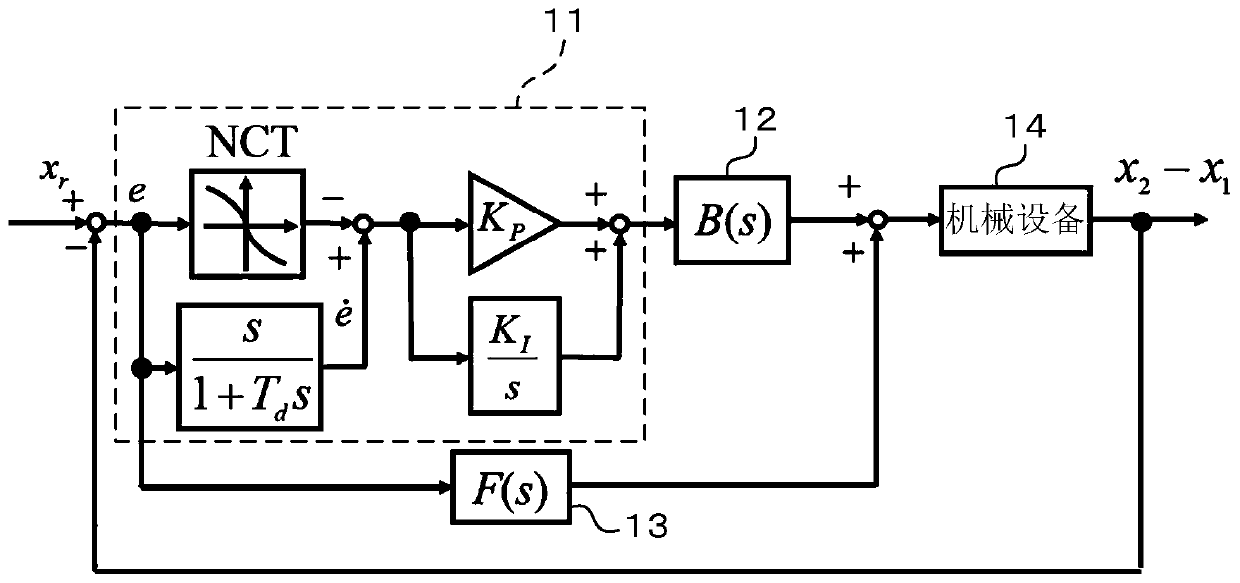

[0037] First, a brief description will be given of the NCTF control system which is the feedback control system which is the basis of the present invention. figure 1 is a block diagram showing the general structure of the NCTF system.

[0038] For the NCTF control system, it is composed of a nominal characteristic trajectory (Nominal CharacteristicTrajectory: NCT) and a PI compensator. The nominal characteristic trajectory is formed according to the desired attenuation characteristics on the phase plane. The movement of the control object (mechanical equipment) is constrained to the NCT, and stops at the origin on the phase plane. NCT is made by simple open-loop experiments, and the optimal value of the gain of the PI compensator is determined through step response and trajectory control experiments. Therefore, the NCTF control system does not require detailed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com