Active and passive vibration isolation platform and method based on electromagnetic negative stiffness in space with six degrees of freedom

A vibration isolation platform and negative stiffness technology, applied in the field of active and passive vibration isolation platforms with six degrees of freedom in space, can solve problems such as inability to adjust flexibly, and achieve the effects of large driving force, fast response speed and low system resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation.

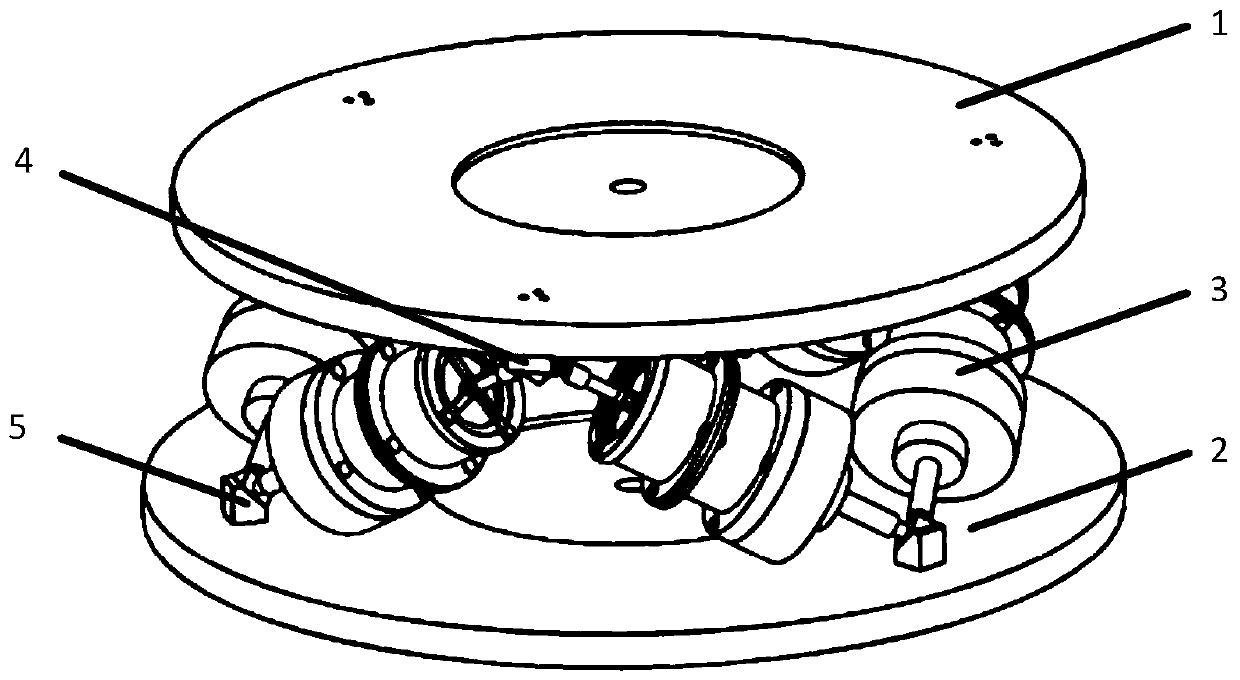

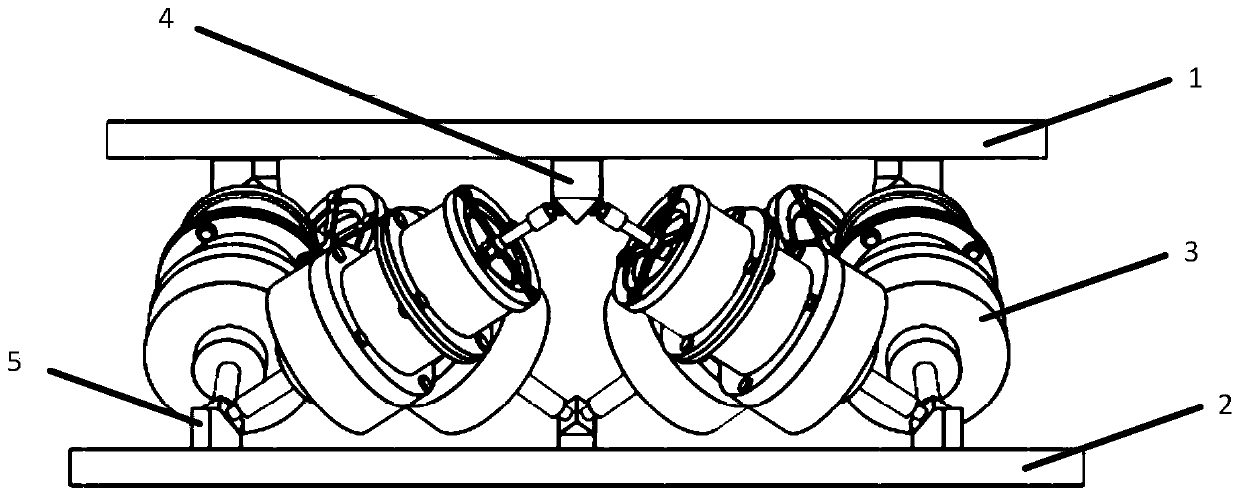

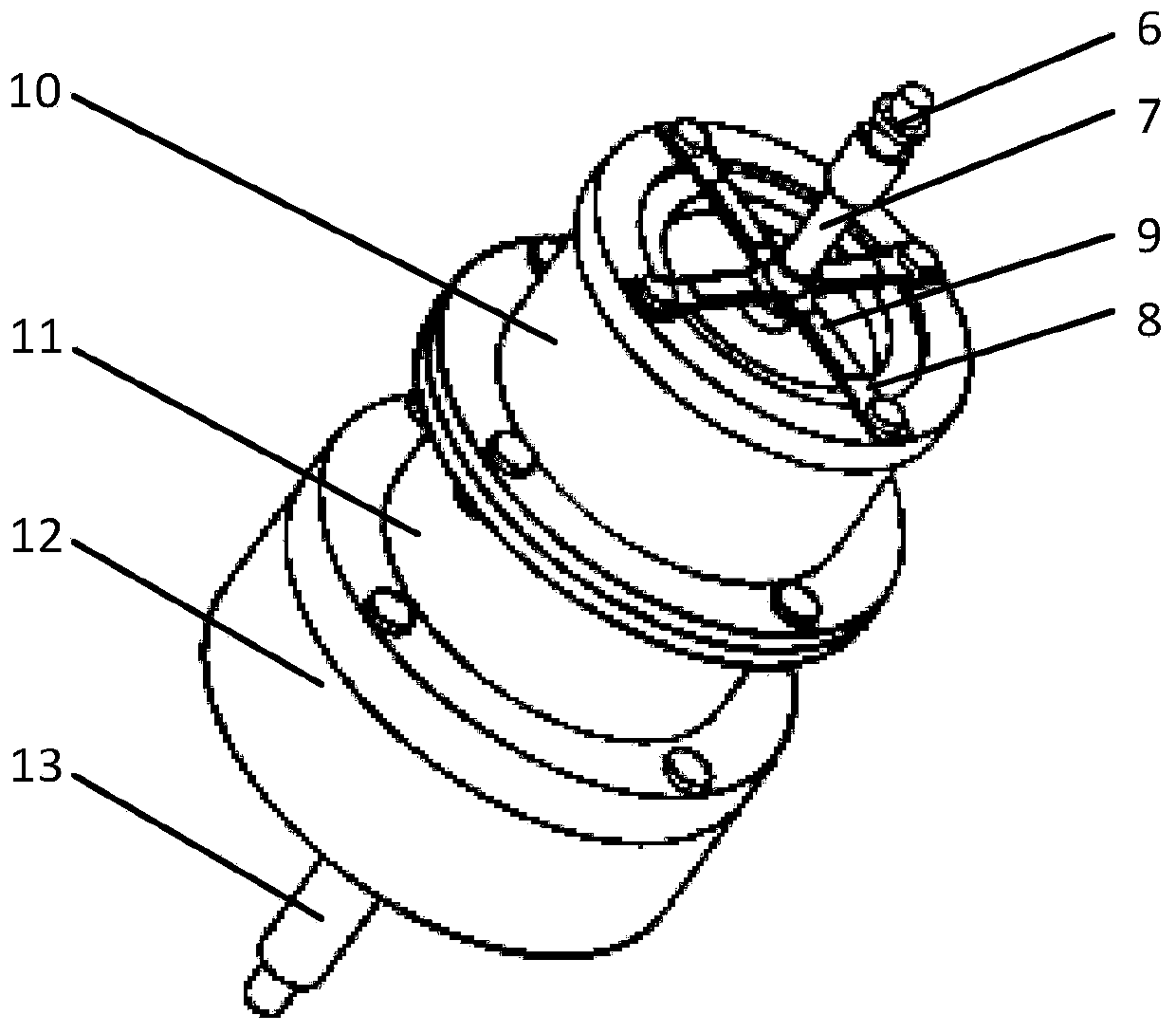

[0022] like figure 1 and figure 2 As shown, the present invention is a space six-degree-of-freedom active and passive vibration isolation platform based on electromagnetic negative stiffness, including a load platform 1, a base platform 2, and six electromagnetic negative stiffness vibration isolators 3 connecting the load platform 1 and the base platform 2. The top of the actuating rod 7 of the electromagnetic negative stiffness vibration isolator 3 is fixedly connected to the universal flexible hinge 6 and connected to the first fixed connection part 4 installed at the lower part of the load platform 1 . The bottom support rod 13 of the electromagnetic negative stiffness vibration isolator 3 is connected with the second fixed connector 5 installed on the foundation platform 2 through threads. Two adjacent electromagnetic negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com