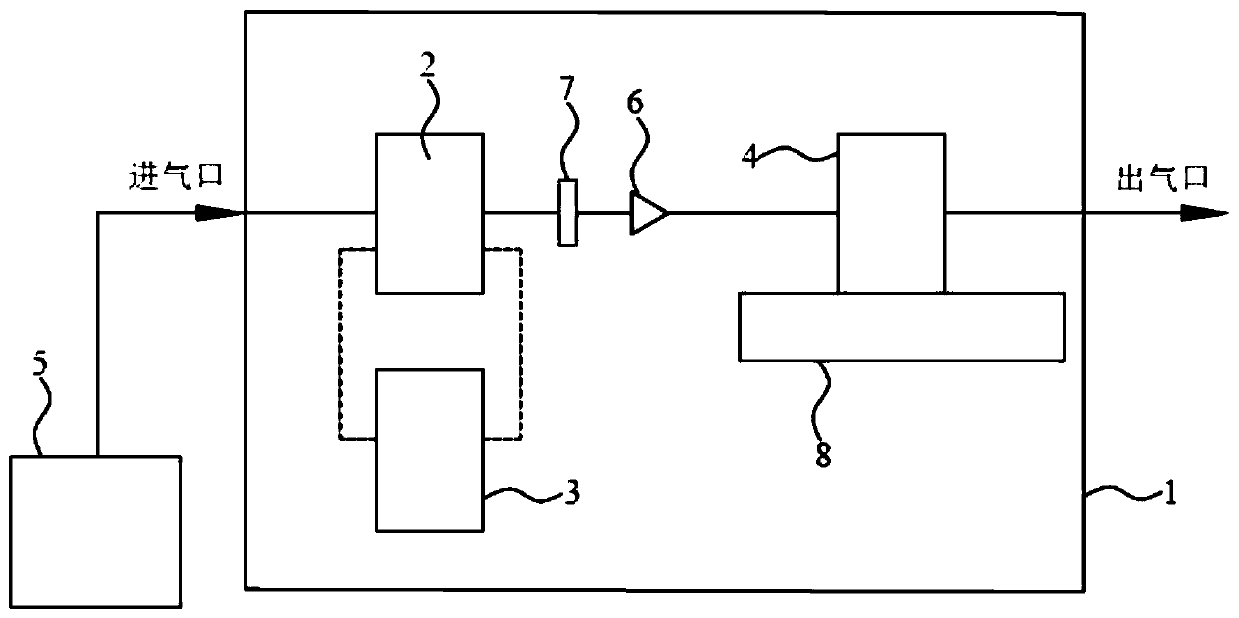

Humidifier humidifying capacity testing device and testing method

A capability testing and humidifier technology, applied in the field of humidifying capability testing devices of humidifiers, can solve problems such as precise control, limitation of input gas flow range, unfavorable input gas temperature, etc., to achieve the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

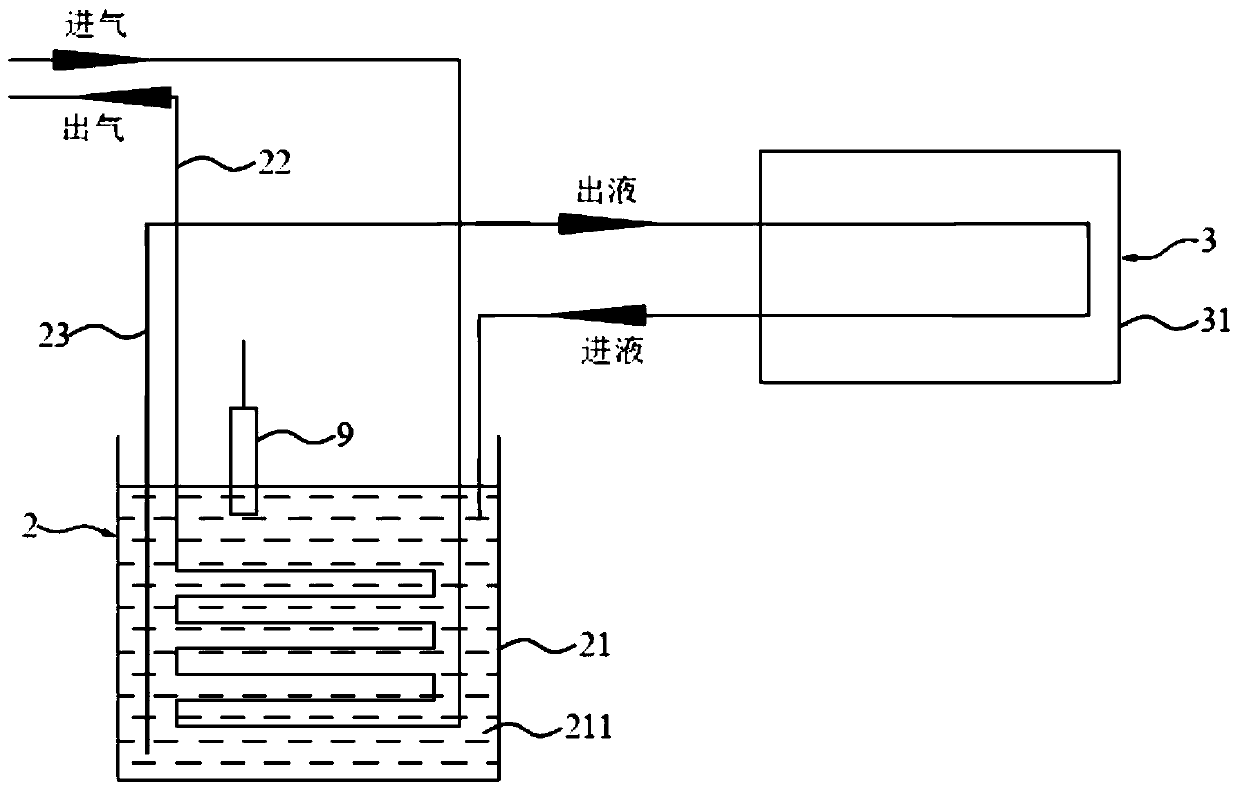

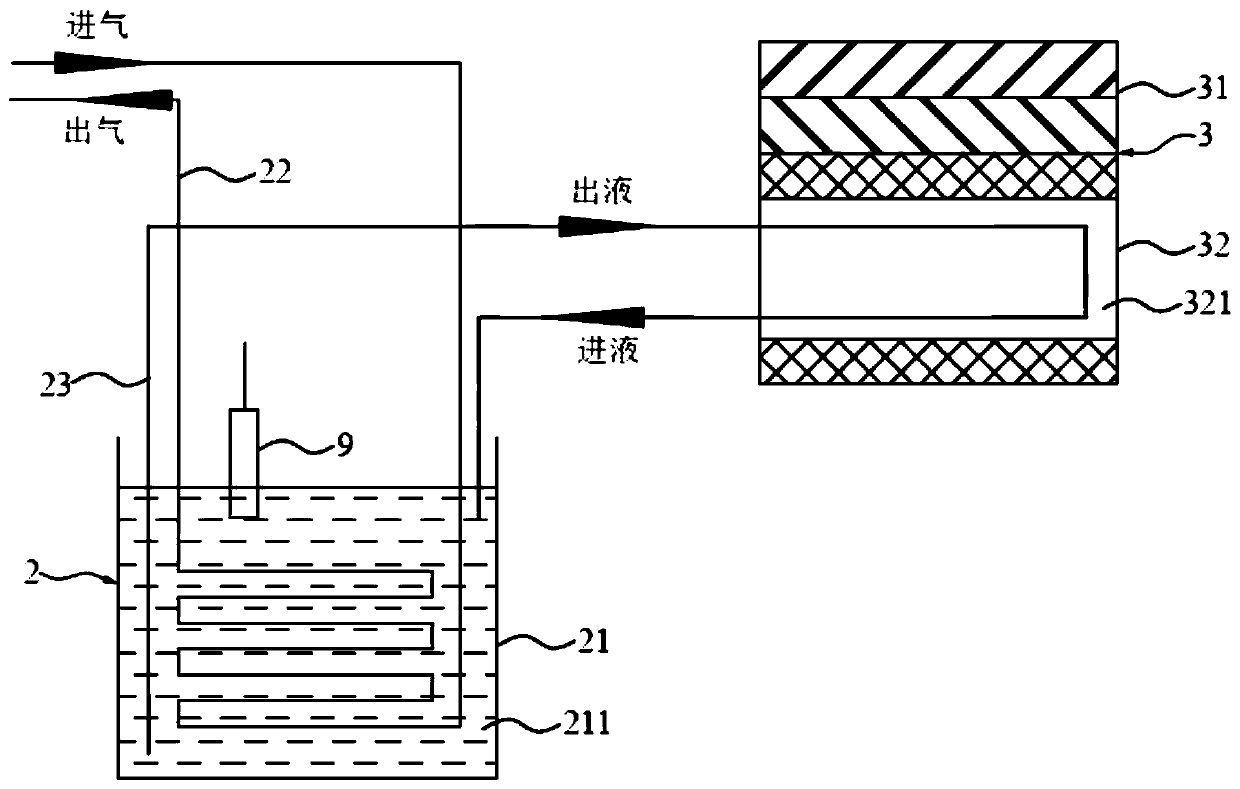

Embodiment Construction

[0064] As mentioned above, the humidifier humidification capacity test device disclosed in the patent application number 201510248962.3 adjusts the temperature of the gas input into the humidifier to be tested through heat exchange between the spiral tube in the gas temperature buffer box and the air. , due to the limitation of the capacity of the heat exchange chamber of the gas temperature buffer box, the flow range of the gas input into the humidifier to be tested may be limited; in addition, due to the small heat capacity and large thermal inertia of the gas, it may be As a result, when the compressor or heater is turned on and off, the temperature of the gas in the heat exchange chamber fluctuates in a large range (generally about ±2 degrees), which is not conducive to the precise control of the temperature of the gas input into the humidifier to be tested.

[0065] Therefore, when it is necessary to input a large flow range of gas into the humidifier under test, firstly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com