Safety pneumatic integrated control valve and control method

An integrated control valve and safety technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of safety and hidden dangers in the electronic control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

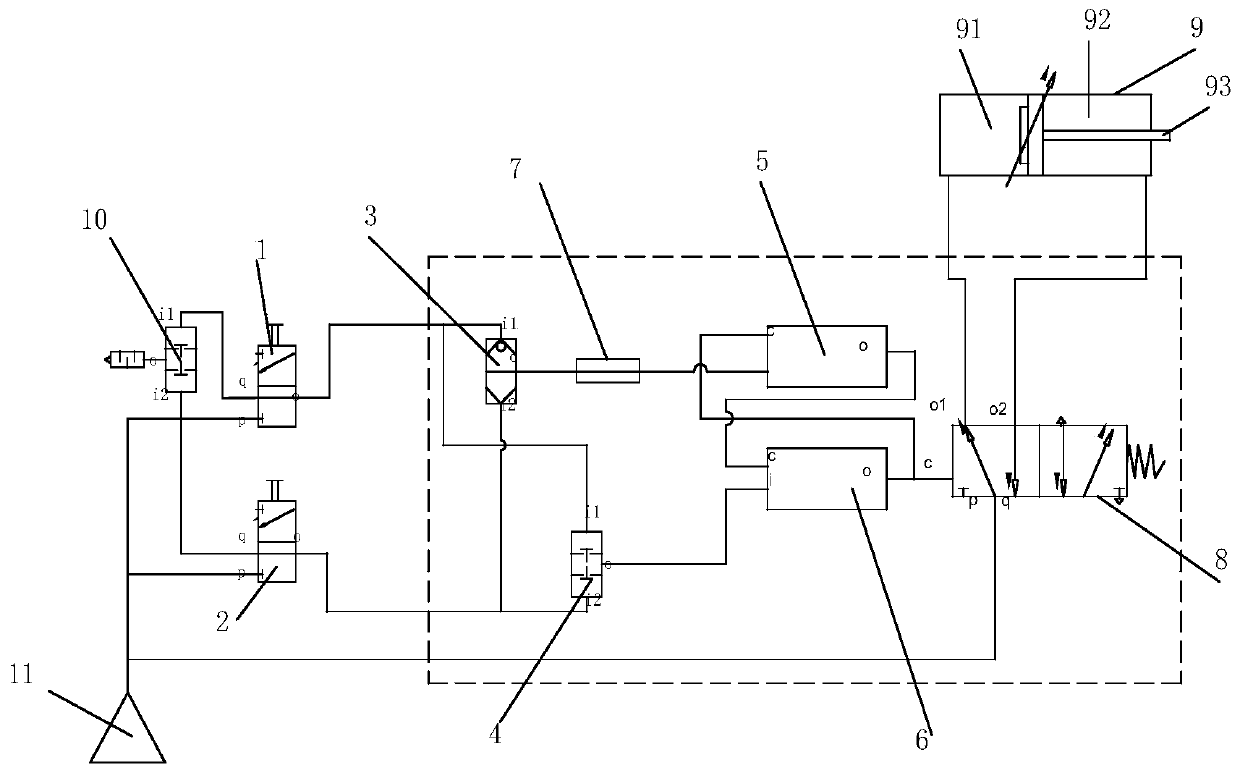

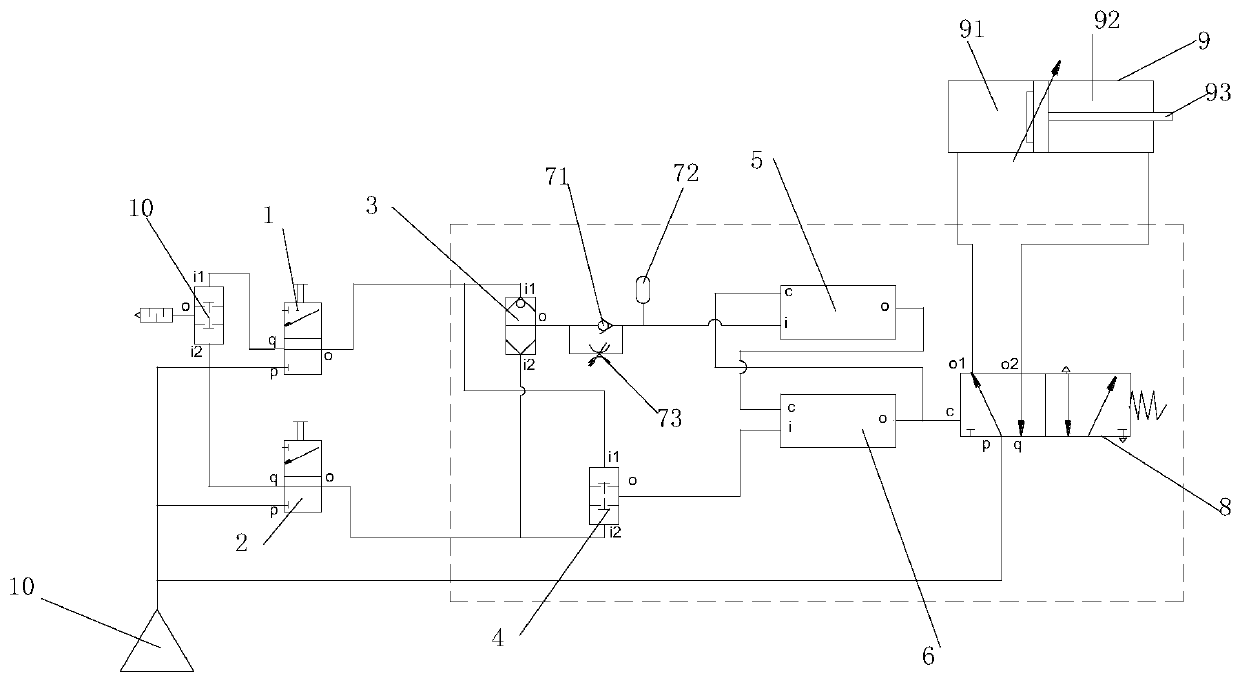

[0041] Such as figure 1 As shown, the present invention provides a preferred embodiment, a safety pneumatic integrated control valve, including two manually operated valves, a first double pressure valve 4, a shuttle valve 3, a forbidden door valve to control the air circuit, a single air control two Position five-way valve 8 and cylinder 9.

[0042] In addition, in order to easily distinguish the various ports of the valve, such as figure 1 As shown, the present invention makes the following marks: o represents the output port, o1 represents the first output port, o2 represents the second output port, i represents the input port, i1 represents the first input port, i2 represents the second input port, p represents the gas Source port, q means exhaust port, and d means air control port.

[0043] Wherein, the manual operation valve is provided with an air source port, an exhaust port and an output port. When the manual operation valve is connected, the air source port is con...

Embodiment 2

[0111] Based on Embodiment 1, the present invention also provides a control method for a safety pneumatic integrated control valve, including the following steps:

[0112] Step (1): When the first manual operation valve and the second manual operation valve are synchronously connected, the pressure first reaches the input port of the second prohibition valve control air circuit of the prohibition valve through the second double pressure valve, so that the second The output port of the ban door valve outputs pressure to the air control end of the single air control two-position five-way valve, and then controls the valve core of the single air control two-position five-way valve to move under the action of pressure against the spring force, so that the single air The air source port of the two-position five-way valve is connected to the first output port of the single-air control two-position five-way valve, and the exhaust port of the single-air control two-position five-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com