Ashless antioxidant lubricating oil additive, compound lubricating oil additive and lubricating oil composition containing same

A lubricating oil additive and anti-oxidation technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of increased mechanical wear, increased viscosity, increased acidity, etc. Oxidizing properties, effects on deposit formation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0079] See Table 1 for the composition and content of the ashless antioxidant lubricating oil additive. In Table 1, RHY***: product grade of China Petroleum Lubricating Oil Company.

[0080] Table 1 Ashless Antioxidant Lubricating Oil Additive Embodiment Table

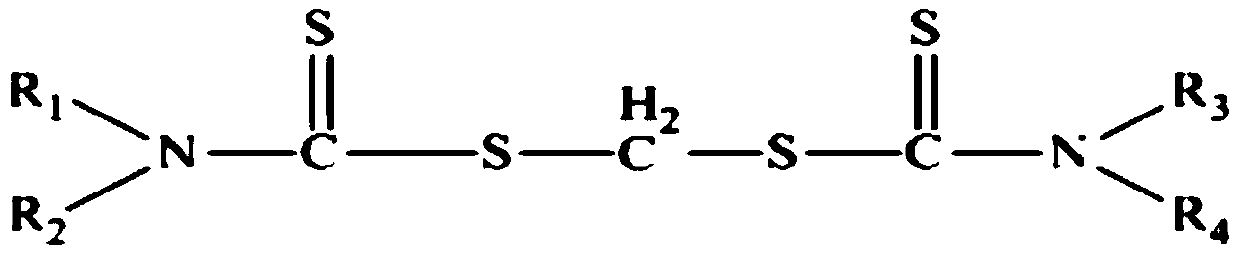

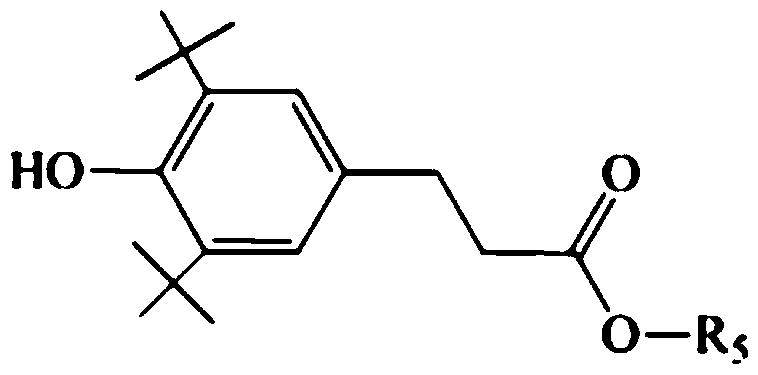

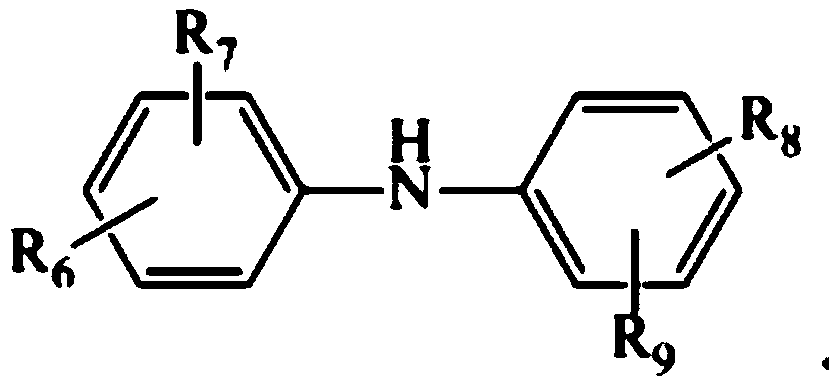

[0081] components Example 1 Example 2 (1) Dibutyldithiocarbamate (RHY512) 0.02% 0.05% (2) Isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate (RHY505) 0.15% 0.10% (3) Butyloctyldiphenylamine (RHY530) 0.15% 0.15% (4) Octylated N-phenyl-a-naphthylamine (RHY532) 0.03% 0.05% Total weight of lubricant 0.35% 0.35%

[0082] The ashless anti-oxidation lubricating oil additive of the present invention can play an excellent anti-oxidation effect when used in various lubricating base oils. While effectively prolonging the oxidation induction period of the oil, it can well control the adverse effects of the acid value increase and viscosity increase caused by the oxidation of t...

Embodiment 3-4

[0084] The ashless antioxidant lubricating oil additives prepared in Example 1 and Example 2 were added to HVIW H150 base oil (from Daqing Petrochemical) at a ratio of 0.35%, respectively, to obtain Example 3 and Example 4.

[0085] Rotating oxygen bomb method (SH / T 0193), pressurized differential scanning calorimetry (PDSC) (SH / T 0719), rapid oxidation stability test method (PetroOxy) (ASTM D7545), static oven oxidation test method ( Self-constructed method, observe the appearance of the oil after testing at 175°C for 96 hours, test the viscosity increase and acid value of the oil at 100°C) to evaluate its anti-oxidation performance, the results are shown in Table 2.

Embodiment 5

[0093] See Table 3 for the components and contents of the ashless antioxidant additive compositions of Example 5, Example 6, Example 7, and Example 8. In Table 3, RHY***: product grade of China Petroleum Lubricating Oil Company.

[0094] Table 3 Ashless Antioxidant Additive Composition Embodiment Table

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com