Unmanned forklift for intelligent warehouse

A technology of unmanned driving and intelligent robots, which is applied in the field of unmanned forklifts for intelligent warehouses, can solve the problems of scarcity of forklift technicians, high manpower and material resources, and high mobility of personnel, so as to achieve low labor intensity, improve enterprise efficiency, The effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

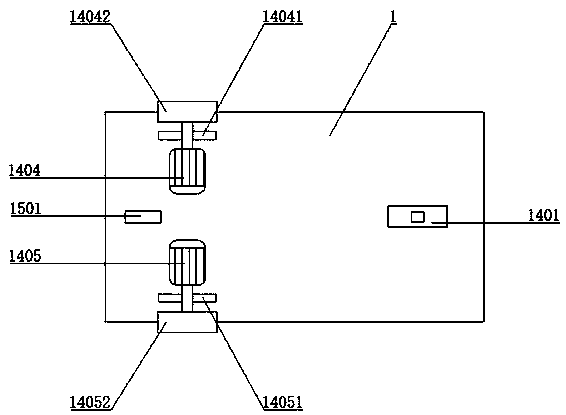

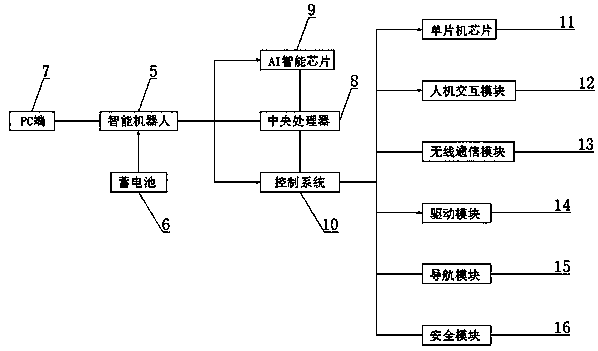

[0042] see Figure 1-8 , an unmanned forklift for an intelligent warehouse, including an intelligent warehouse, a trolley floor 1 and a head 2, the head 2 is fixedly connected to the front end of the trolley floor 1, and a chute 3 is dug into the inner wall of the head 2, and the chute 3 acts as a limiter , the bottom end of the chute 3 is slidably connected with a forklift block 4, the forklift block 4 is used to place goods, and a pressure sensor 401 is embedded in the interior of the forklift block 4 near the upper end, and the pressure sensor 401 is used to sense the gravity of the goods. The bottom plate of the trolley 1 A battery slot 17 is excavated at the upper end of the battery slot 17, and a battery 6 is clamped at the inner end of the battery slot 17. The battery slot 17 is used for installing the battery 6, and the battery 6 is used for power supply. It is used for receiving instructions and feedback instructions at the same time, and also plays a control role. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com