Movable mounting base for ship electrical equipment

A technology for electrical equipment and installation bases, applied in the field of movable installation bases, can solve the problems of limited space, large modification and modification workload, etc., and achieve the effect of convenient on-site construction, convenient equipment use, and improved maintenance space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

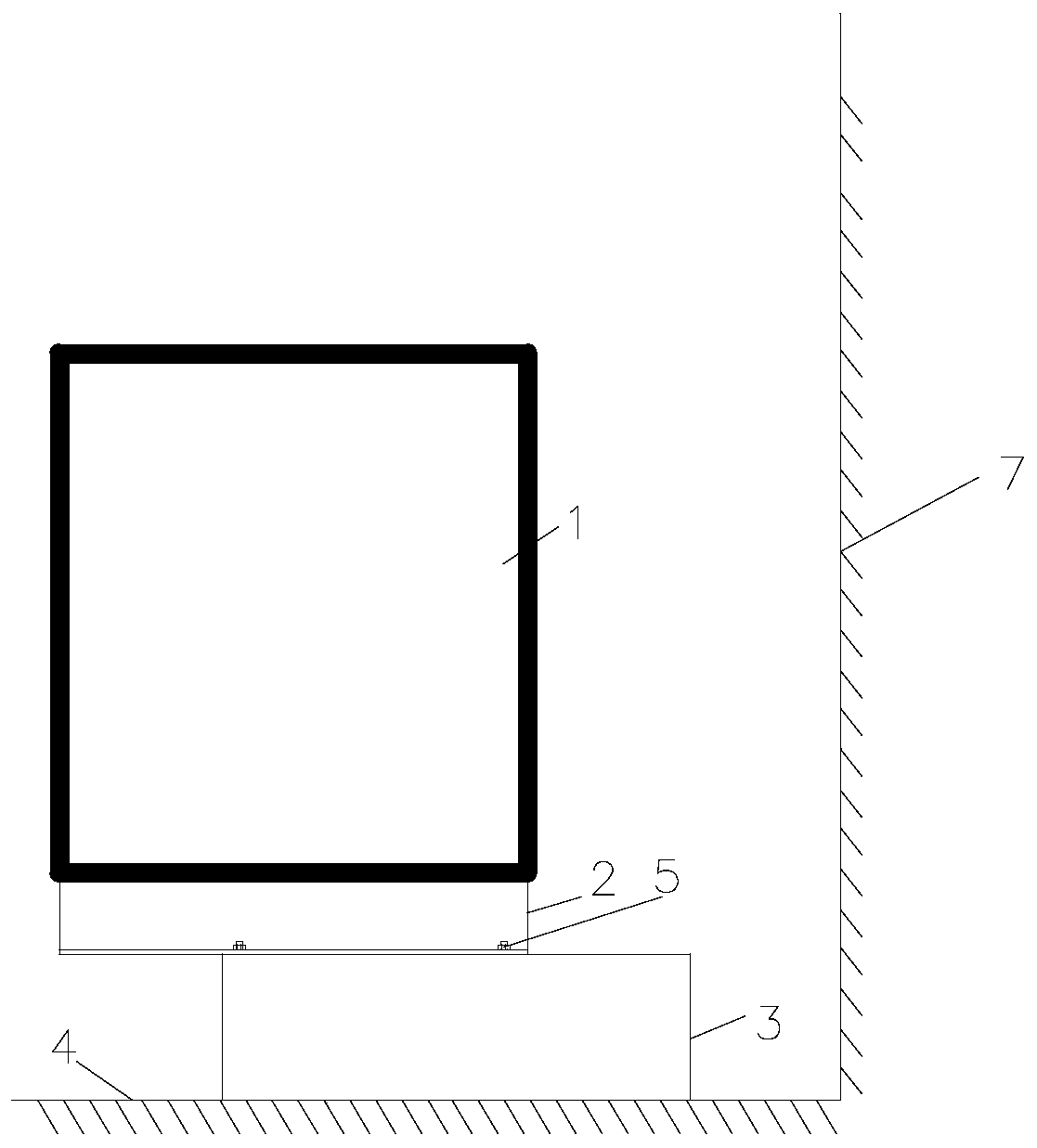

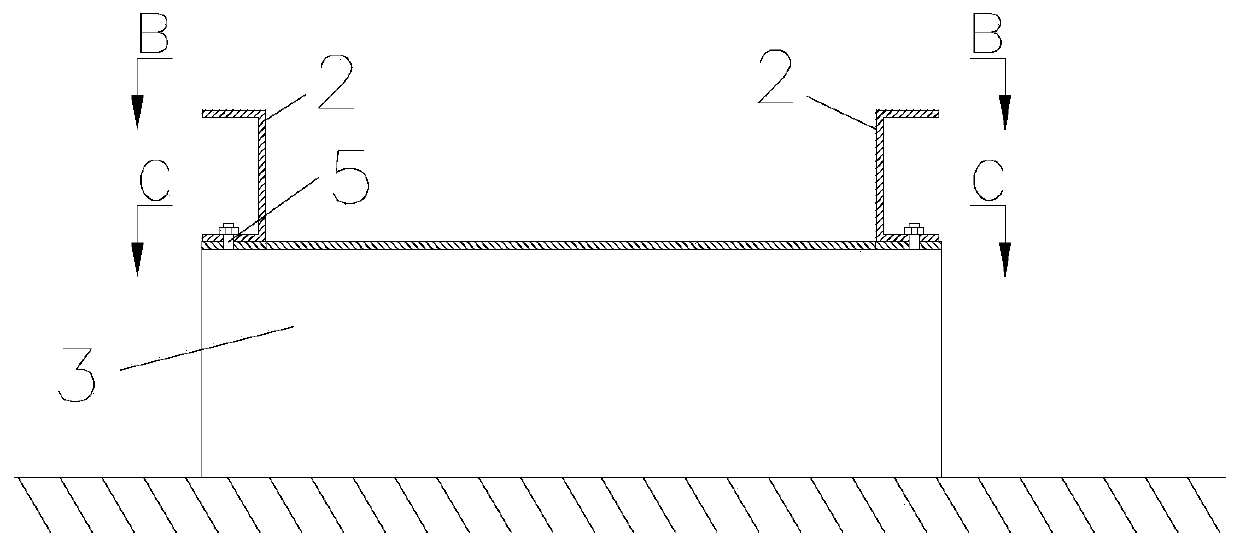

[0032] like figure 1 and figure 2 As shown, this embodiment provides a movable installation base for electrical equipment 1 of a ship. The electrical equipment 1 is placed in the cabin of the ship. The installation base includes a fixed module 3, a mobile module 2 and a connection assembly 5. The fixed module 3 is fixedly installed on the deck 4 of the cabin, the upper end of the fixed module 3 is movably connected with the lower end of the mobile module 2 through the connection assembly 5 , and the electrical equipment 1 is fixedly connected with the upper end of the mobile module 2 .

[0033] The fixed module 3 is fixedly connected with the deck 4, which can be arranged at a position close to the cabin bulkhead 7, and then the electrical equipment 1 is fixedly connected with the mobile module 2, because the mobile module 2 is slidably connected with the fixed module 3, in the working state, such as figure 1 As shown, the electrical equipment 1 is closer to the bulkhead 7, ...

no. 2 approach

[0042] like Image 6 and Figure 7As shown, the mobile module 2 of the present embodiment has the same structure as the mobile module 2 of the previous embodiment, but the fixed module 3 of the present embodiment includes a moving block 10, a fixed block 8 and a supporting block 9, and the lower side of the fixed block 8 is connected to the The deck 4 of the cabin is fixedly connected, the inclined surface of the fixed block 8 is slidably connected with the inclined surface of the moving block 10, and the upper side of the moving block 10 is the upper side of the fixed module 3;

[0043] Both the moving block 10 and the fixed block 8 are right-angled triangular prisms, the inclined surfaces of the two right-angled triangular prisms are slidable, and the right-angled faces and sides of the two right-angled triangular prisms form a rectangular block, and the apex side of the fixed block 8 faces the bulkhead 7 of the cabin , the inclined surface of the fixed block 8 is provided ...

Embodiment approach

[0050] like Image 6 and Figure 7 As shown, this embodiment is actually a supplementary embodiment of the second embodiment. On the basis of the second embodiment, a support assembly 11 is added on the fixed block 8. The support assembly 11 includes a first support plate 14, a second Two support plates 13 and a telescopic support bar 12, the first support plate 14 and the second support plate 13 are arranged in parallel, and the two ends of the telescopic support bar 12 are respectively fixedly connected with the first support plate 14 and the second support plate 13, The first support plate 14 is supported on the bottom surface of the mobile block 10, the second support plate 13 is supported on the bulkhead 7, and the telescopic support rod 12 is a manual air pressure telescopic rod, a manual hydraulic telescopic rod or an electric telescopic rod, which is telescopic. The number of support rods 12 is at least two, and they are all arranged in parallel.

[0051] The reason ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com