Nanocrystallization homogenizing and sterilizing all-in-one machine

A kind of nanometerization and all-in-one machine technology, which is applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as difficult to achieve, high pressure, influence on homogenization effect, etc., to improve transmission efficiency and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

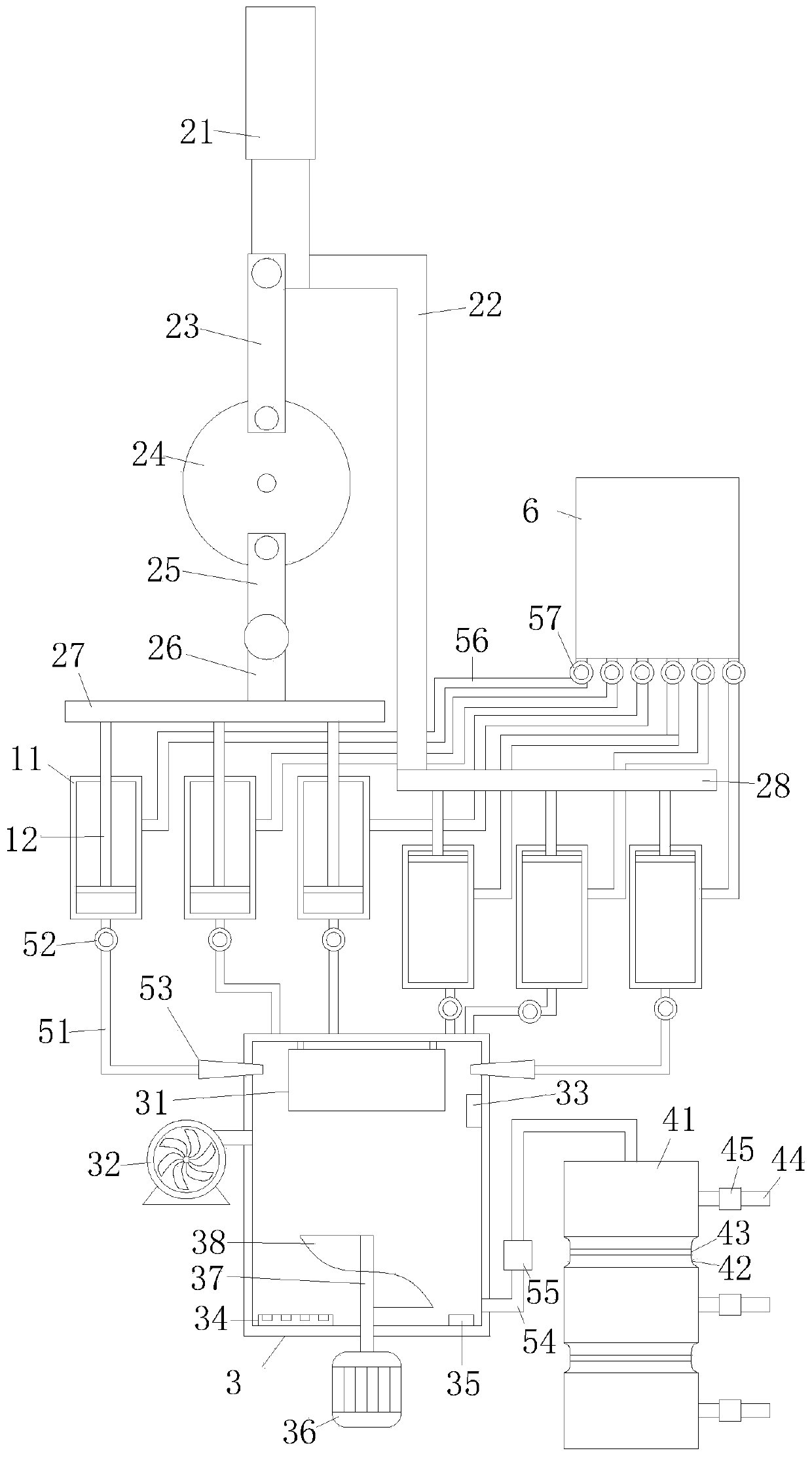

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0019] Such as figure 1 As shown, the embodiment provides a nano-scale homogenization and sterilization integrated machine, including a homogenization component, a transfer cylinder 3, and an output component. The homogenization unit includes multiple pressure pumps and driving devices, and the multiple pressure pumps are arranged horizontally. The pressure pump includes a pressure cylinder 11 and a pressure rod 12. The pressure rod 12 extends through the pressure rod 12 to the inside of the pressure rod 12. The driving device includes a hydraulic cylinder 21 , The first push rod 22, the second push rod 23, the third push rod 25, the fourth push rod 26, the rotating disk 24, the first butt plate 28, the second back plate 27. The hydraulic cylinder 21 is arranged above the pressure pump, the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com