A kind of nano-magnesium lithium silicate coated high-nickel positive electrode material and its preparation method and application

A technology of lithium magnesium silicate and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problem of not being able to fully coat, and achieve the effect of reducing the occurrence of side reactions, slowing down the denaturation speed, and improving the storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

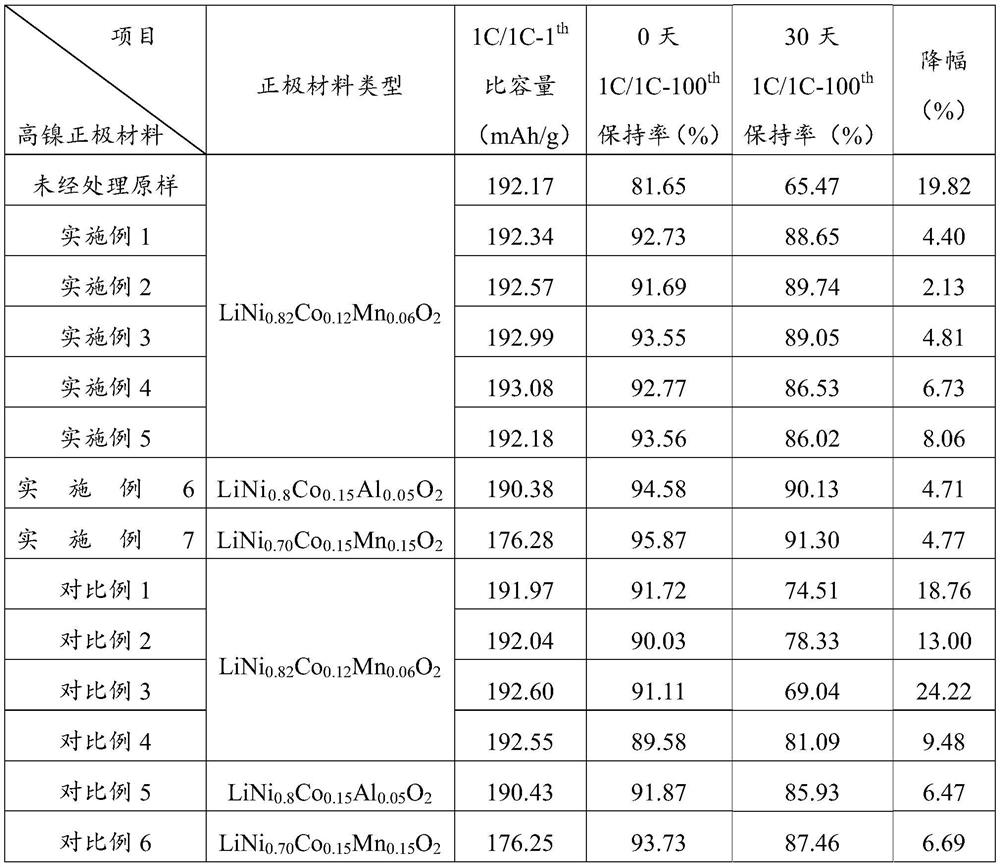

Embodiment 1

[0033] This embodiment provides a nano-lithium magnesium silicate coated high-nickel positive electrode material, the preparation method of which comprises the following steps:

[0034] (1) Preparation of nano-lithium magnesium silicate

[0035] 5.00g of H 2 SiO 3 Add it to a beaker with 1L of pure water, then add 1.79g LiOH·H while stirring 2 O and 2.49g Mg(OH) 2 , continue to stir for 30 minutes after the addition is completed, and finally spray and collect nano-magnesium lithium silicate Li 2 Mg 2 (SiO 3 ) 3 ;

[0036] (2) Mixing

[0037]Combine battery-grade lithium hydroxide with high-nickel cathode material precursor Ni 0.82 co 0.12 mn 0.06 (OH) 2 Add it into a high-speed mixer at a molar ratio of 1.04:1 and mix for 25 minutes until it is evenly mixed to obtain a mixed material;

[0038] (3) Primary roasting

[0039] The mixed material obtained in step (2) is roasted in an oxygen atmosphere roller furnace at 750°C for 12 hours. After the roasting is complet...

Embodiment 2

[0043] This embodiment provides a nano-lithium magnesium silicate coated high-nickel positive electrode material. 2 Mg 2 (SiO 3 ) 3 And a roasted semi-finished product; a roasted semi-finished product and nano-lithium magnesium silicate Li 2 Mg 2 (SiO 3 ) 3 Mix evenly according to the weight ratio of 1:0.0033, then roast in an oxygen atmosphere roller furnace at 320°C for 6 hours, cool naturally to room temperature after roasting, pulverize after being released from the furnace, and pass through a 400-mesh sieve to obtain the described Nano-lithium magnesium silicate coated high-nickel cathode material.

Embodiment 3

[0045] This embodiment provides a nano-lithium magnesium silicate coated high-nickel positive electrode material. 2 Mg 2 (SiO 3 ) 3 And a roasted semi-finished product; a roasted semi-finished product and nano-lithium magnesium silicate Li 2 Mg 2 (SiO 3 ) 3 Mix evenly according to the weight ratio of 1:0.0050, then roast in an oxygen atmosphere roller furnace at 320°C for 6 hours, cool naturally to room temperature after roasting, pulverize after being released from the furnace, and pass through a 400-mesh sieve to obtain the described Nano-lithium magnesium silicate coated high-nickel cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com