Intelligent card chip mounting visual detection system and detection method

A smart card chip and visual inspection technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as missed inspections and false inspections, and achieve the effects of reducing production costs, improving quality, and eliminating hidden dangers of product defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

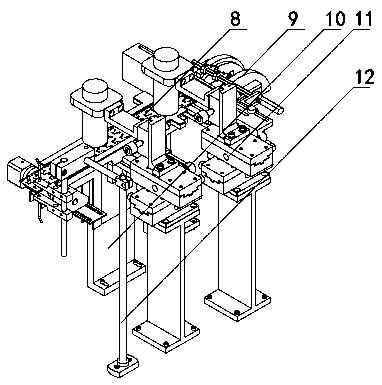

[0056] Figure 1~13 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~13 The present invention will be further described.

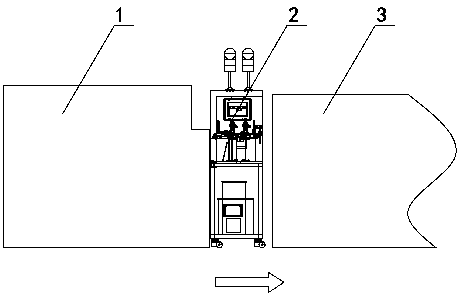

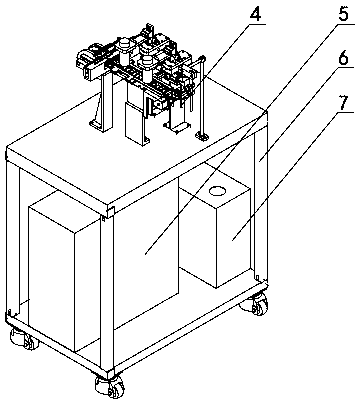

[0057] Such as figure 1 As shown, the smart card chip mounting visual inspection system (hereinafter referred to as the visual inspection system) includes a visual inspection mechanism 2 placed between the placement machine 1 and the curing furnace 3 of the traditional smart card production line. The carrier tape 8 of the chip is inspected and analyzed for defects, and the operating parameters of the chip mounter 1 are adjusted according to the defect feedback, so as to prevent a large number of defective products from entering the curing furnace 3 and effectively avoid economic losses. The direction of the arrow in the figure is The running direction of the carrier tape 8, in this application, is defined as the running direction of the carrier tape 8 from left to right, so other relative positions (directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com